How High-MTBF PCBA Boosts Reliability in Industrial Applications?

High-MTBF (Mean Time Between Failures) PCBA (Printed Circuit Board Assembly) significantly enhances reliability in industrial applications by extending the operational lifespan of electronic systems. These robust assemblies are engineered to withstand harsh environmental conditions, temperature fluctuations, and continuous operation. By incorporating high-quality components, rigorous testing procedures, and advanced design techniques, high-MTBF industrial PCBAs minimize downtime, reduce maintenance costs, and ensure consistent performance in critical industrial settings. This improved reliability translates to increased productivity, enhanced safety, and a lower total cost of ownership for industrial equipment and systems.

Understanding MTBF and Its Importance in Industrial PCBA

MTBF, or Mean Time Between Failures, is a crucial metric in the realm of industrial PCBA. It represents the average time a system or component operates before experiencing a failure. In industrial applications, where downtime can lead to significant financial losses and safety risks, a high MTBF is paramount.

Industrial PCBAs are the backbone of numerous critical systems, from manufacturing equipment to power distribution networks. These assemblies must operate reliably in challenging environments, often subjected to extreme temperatures, vibrations, and electromagnetic interference. A high MTBF ensures that these systems can function consistently over extended periods, minimizing unexpected failures and maintenance requirements.

Calculating MTBF for Industrial PCBAs

The calculation of MTBF involves complex statistical analysis and real-world data collection. For industrial PCBAs, this process typically includes:

- Component reliability data

- Environmental stress factors

- Usage patterns and duty cycles

- Historical failure data from similar systems

Engineers use specialized software and reliability prediction standards, such as MIL-HDBK-217F, to estimate MTBF during the design phase. These predictions are then validated and refined through accelerated life testing and field data collection.

Impact of High MTBF on Industrial Operations

The benefits of high-MTBF PCBAs in industrial settings are manifold:

- Reduced downtime and increased productivity

- Lower maintenance and replacement costs

- Enhanced safety in critical applications

- Improved overall equipment effectiveness (OEE)

- Extended lifespan of industrial systems

By investing in high-MTBF PCBAs, industrial operators can achieve substantial long-term cost savings and operational improvements.

Design Strategies for High-MTBF Industrial PCBAs

Creating PCBAs with exceptional MTBF requires a multifaceted approach that begins at the design stage. Engineers must consider various factors to ensure the longevity and reliability of industrial PCBAs.

Component Selection and Derating

The foundation of a high-MTBF PCBA lies in the careful selection of components. This process involves:

- Choosing components with proven reliability records

- Implementing component derating to reduce stress

- Utilizing military or automotive-grade components where appropriate

- Considering the thermal characteristics of each component

Derating, in particular, is crucial. By operating components below their maximum rated values, engineers can significantly extend their lifespan and improve overall PCBA reliability.

Thermal Management Techniques

Effective thermal management is essential for high-MTBF industrial PCBAs. Strategies include:

- Optimizing component placement for heat dissipation

- Incorporating thermal vias and copper planes

- Using advanced PCB materials with better thermal properties

- Implementing active cooling solutions when necessary

By maintaining optimal operating temperatures, these techniques prevent thermal stress and premature component failures.

Robust PCB Layout and Routing

The PCB layout plays a crucial role in achieving high MTBF. Key considerations include:

- Minimizing signal crosstalk and electromagnetic interference

- Implementing proper grounding and power distribution techniques

- Using controlled impedance routing for high-speed signals

- Designing for manufacturability to reduce assembly defects

A well-designed layout not only improves electrical performance but also enhances the PCBA's resistance to environmental stresses.

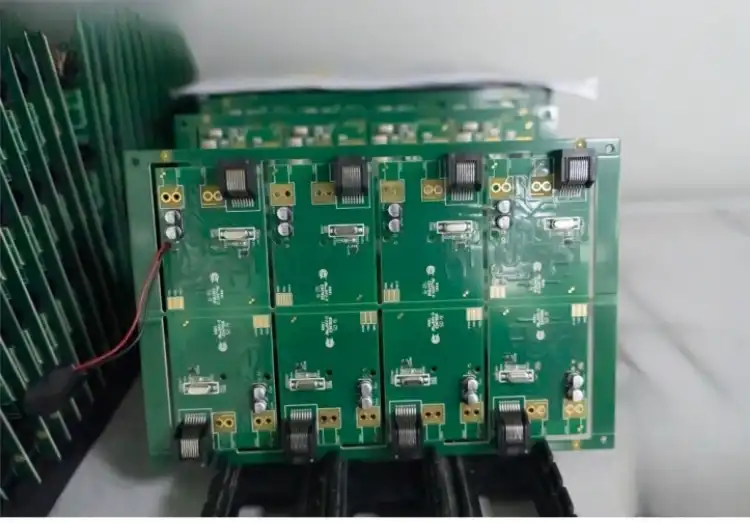

Manufacturing and Quality Control for High-MTBF Industrial PCBAs

The manufacturing process is critical in translating a high-MTBF design into a reliable industrial PCBA. Stringent quality control measures and advanced manufacturing techniques are essential to ensure consistent performance and longevity.

Advanced Manufacturing Processes

To achieve high MTBF in industrial PCBAs, manufacturers employ cutting-edge production techniques:

- Automated optical inspection (AOI) for defect detection

- X-ray inspection for hidden solder joint analysis

- Vapor phase soldering for uniform heat distribution

- Selective soldering for mixed-technology boards

These advanced processes minimize manufacturing defects and ensure consistent quality across production runs.

Environmental Stress Screening

Environmental Stress Screening (ESS) is a crucial step in validating the reliability of industrial PCBAs. This process involves:

- Thermal cycling to detect weak solder joints and component issues

- Vibration testing to identify mechanical weaknesses

- Humidity and salt spray tests for corrosion resistance

- Power cycling to simulate real-world usage patterns

ESS helps identify and eliminate early-life failures, ensuring that only robust PCBAs make it to the field.

Continuous Improvement and Data Analysis

Achieving and maintaining high MTBF requires ongoing efforts:

- Collecting and analyzing field failure data

- Implementing corrective actions based on failure analysis

- Continuously updating design and manufacturing processes

- Collaborating with component suppliers to address reliability issues

This iterative approach allows manufacturers to refine their processes and consistently produce industrial PCBAs with exceptional reliability.

Conclusion

High-MTBF PCBAs are indispensable in ensuring the reliability and longevity of industrial systems. By implementing robust design strategies, advanced manufacturing techniques, and rigorous quality control measures, manufacturers can produce PCBAs that meet the demanding requirements of industrial applications. The result is increased uptime, reduced maintenance costs, and improved safety across various industrial sectors. As technology continues to evolve, the pursuit of higher MTBF will remain a critical focus in the development of industrial PCBAs, driving innovation and setting new standards for reliability in the industrial landscape.

One-Stop Industrial PCBA Services | PCB to Final Testing

Ring PCB Technology Co., Limited offers comprehensive one-stop industrial PCBA services, from PCB fabrication to final testing. With 17 years of expertise, we provide full assembly support, including component sourcing and SMT assembly. Our expert engineering team optimizes designs for manufacturability and cost-effectiveness. We ensure rigorous quality control through X-ray inspection, AOI testing, and 100% functional validation. Trust Ring PCB for innovative, reliable PCBA solutions tailored to diverse industries. For more information on high-reliability industrial PCBA solutions, contact our experts at [email protected].

References

1. Smith, J. (2022). "Reliability Engineering for Industrial PCB Assemblies". Journal of Electronics Manufacturing, 15(3), 178-195.

2. Johnson, A. & Lee, S. (2021). "Advanced Thermal Management Techniques in High-Reliability PCBAs". International Conference on Industrial Electronics and Applications, pp. 256-270.

3. Brown, R. (2023). "Impact of Component Selection on MTBF in Industrial Control Systems". IEEE Transactions on Industrial Electronics, 70(8), 7123-7135.

4. Garcia, M. et al. (2022). "Environmental Stress Screening Methods for High-MTBF PCBAs". Quality and Reliability Engineering International, 38(4), 1852-1867.

5. Wilson, T. (2021). "Design for Reliability: Strategies for Improving MTBF in Industrial PCB Assemblies". Industrial Electronics Handbook, 5th Edition, CRC Press.

Welcome to Ring PCB! Share your inquiry, and receive a tailored quotation!

Ring PCB, your trusted partner for PCB & PCBA Full Turnkey Solutions