How Medical PCBA Powers Advanced Diagnostic Devices?

Medical Printed Circuit Board Assembly (PCBA) is the cornerstone of advanced diagnostic devices, revolutionizing healthcare through precision and reliability. These sophisticated assemblies integrate cutting-edge components and circuitry, enabling diagnostic equipment to perform complex analyses with unprecedented accuracy. From portable ultrasound machines to advanced MRI scanners, medical PCBAs process vast amounts of data, control sensitive sensors, and facilitate real-time image processing. Their compact design and high-performance capabilities allow for miniaturization of diagnostic tools, making healthcare more accessible and efficient. Essentially, medical PCBAs serve as the brain and nervous system of modern diagnostic devices, powering innovations that lead to earlier detection, more accurate diagnoses, and ultimately, better patient outcomes.

The Evolution of Medical PCBAs in Diagnostic Technology

From Analog to Digital: A Paradigm Shift in Diagnostics

The journey of medical PCBAs in diagnostic technology is a testament to the rapid advancements in electronics and healthcare. In the early days, diagnostic devices relied heavily on analog circuitry, which limited their capabilities and accuracy. The transition to digital PCBAs marked a significant turning point, enabling more sophisticated data processing and analysis.

Digital medical PCBAs introduced the ability to capture, store, and analyze vast amounts of patient data with unprecedented precision. This shift allowed for the development of more compact and portable diagnostic tools, making healthcare more accessible even in remote areas. The integration of microprocessors and specialized chips in medical PCBAs facilitated real-time data processing, enabling instant results and faster decision-making for healthcare professionals.

Miniaturization and Increased Functionality

As PCBA technology progressed, a trend towards miniaturization emerged, paralleling the broader developments in the electronics industry. This miniaturization had profound implications for medical diagnostics. Smaller, more densely packed PCBAs allowed for the creation of handheld ultrasound devices, portable ECG monitors, and even ingestible diagnostic capsules.

The reduction in size did not come at the cost of functionality. On the contrary, modern medical PCBAs pack more features and capabilities into smaller footprints. Multi-layer PCB designs, surface-mount technology (SMT), and advanced materials have all contributed to this trend. These compact yet powerful PCBAs have enabled the development of point-of-care testing devices, bringing laboratory-grade diagnostics to the bedside and even to patients' homes.

Integration of Artificial Intelligence and Machine Learning

The latest frontier in medical PCBA evolution is the integration of artificial intelligence (AI) and machine learning (ML) capabilities. PCBAs now incorporate powerful processors capable of running complex algorithms directly on the device. This on-board intelligence enhances diagnostic accuracy, enables predictive analytics, and supports decision-making processes.

AI-enabled medical PCBAs can analyze patterns in diagnostic data that might be imperceptible to human observers. For instance, in medical imaging, AI algorithms running on specialized PCBAs can detect subtle abnormalities in X-rays or MRI scans, potentially identifying diseases at earlier stages. This integration of AI and ML not only improves diagnostic accuracy but also paves the way for personalized medicine, where diagnostic devices can adapt and improve their performance based on individual patient data.

Key Components and Design Considerations in Medical PCBAs

Critical Components for Diagnostic Precision

The heart of any medical PCBA lies in its carefully selected components, each playing a crucial role in ensuring diagnostic accuracy and reliability. High-precision analog-to-digital converters (ADCs) are fundamental, translating analog signals from sensors into digital data for processing. These ADCs must offer high resolution and low noise to capture even the most subtle physiological signals accurately.

Microcontrollers or specialized processors form the brain of the PCBA, orchestrating data flow and executing complex algorithms. In advanced diagnostic devices, field-programmable gate arrays (FPGAs) or application-specific integrated circuits (ASICs) may be employed for tasks requiring high-speed, parallel processing, such as real-time image reconstruction in ultrasound systems.

Design Considerations for Medical-Grade PCBAs

Designing PCBAs for medical diagnostic devices involves a unique set of challenges and considerations. Electromagnetic compatibility (EMC) is paramount, as medical devices must operate reliably in environments with various electronic equipment. This necessitates careful PCB layout, including proper grounding, shielding, and signal isolation techniques.

Thermal management is another crucial aspect, especially in compact devices where components are densely packed. Efficient heat dissipation is essential to maintain the accuracy of sensitive components and ensure the longevity of the device. This may involve the use of thermal vias, heat sinks, or even active cooling solutions in high-performance diagnostic equipment.

Reliability and longevity are non-negotiable in medical PCBAs. This demands the use of high-quality, medical-grade components capable of withstanding rigorous use and sterilization processes. Conformal coatings are often applied to protect the PCBA from moisture, chemicals, and environmental contaminants, ensuring consistent performance over the device's lifetime.

Regulatory Compliance and Quality Assurance

Medical PCBAs must adhere to stringent regulatory standards, including FDA regulations in the United States and CE marking requirements in Europe. This compliance extends beyond the final product to the PCBA manufacturing process itself. Traceability of components and manufacturing processes is essential, necessitating robust documentation and quality control systems.

Quality assurance in medical PCBA production involves multiple stages of testing and validation. Automated optical inspection (AOI) and X-ray inspection are commonly used to detect manufacturing defects. Functional testing simulates real-world usage scenarios to ensure the PCBA performs as intended. Environmental stress screening (ESS) may be employed to identify potential weaknesses or early failure modes.

The design and manufacturing of medical PCBAs also must comply with standards such as IPC-A-610 Class 3, which sets the highest acceptability requirements for electronic assemblies. This ensures that the PCBAs meet the exacting standards required for critical applications where failure is not an option.

Future Trends and Innovations in Medical PCBA for Diagnostics

Advancements in Flexible and Wearable Diagnostics

The future of medical PCBAs in diagnostics is poised for revolutionary changes, with flexible and wearable technologies at the forefront. Flexible PCBAs, capable of conforming to irregular shapes, are opening new possibilities in wearable diagnostic devices. These pliable circuits can be integrated into skin patches, clothing, or even implantable devices, allowing for continuous, non-invasive monitoring of vital signs and other health parameters.

Advancements in materials science are driving this trend, with the development of stretchable conductive inks and flexible substrates that maintain electrical integrity under bending and stretching. This technology enables the creation of "smart bandages" that can monitor wound healing, or wearable ECG monitors that provide long-term cardiac data without the discomfort of traditional electrodes.

The integration of these flexible PCBAs with energy harvesting technologies is another exciting frontier. By harnessing energy from body heat or movement, these diagnostic devices could potentially operate without batteries, greatly extending their usability and reducing maintenance needs.

Integration of Nanotechnology in Diagnostic PCBAs

Nanotechnology is set to play a transformative role in the next generation of medical PCBAs for diagnostics. At the nanoscale, materials exhibit unique properties that can dramatically enhance the sensitivity and specificity of diagnostic tests. Nanostructured surfaces on PCBAs can increase the surface area for biochemical reactions, leading to more sensitive and faster diagnostic assays.

The integration of nano-sensors into PCBAs promises to revolutionize point-of-care diagnostics. These sensors can detect minute quantities of biomarkers, potentially allowing for early detection of diseases at the molecular level. For instance, nano-enabled PCBAs could lead to breath analyzers capable of detecting cancer markers or blood glucose monitors that require only a fraction of the current sample size.

The Role of 5G and IoT in Connected Diagnostics

The advent of 5G technology and the Internet of Things (IoT) is set to revolutionize connected diagnostics, with medical PCBAs at the heart of this transformation. 5G's high-speed, low-latency connectivity will enable real-time transmission of large datasets from diagnostic devices to cloud-based AI systems for instant analysis. This could facilitate remote diagnostics and telemedicine on an unprecedented scale.

IoT-enabled medical PCBAs will form the backbone of interconnected diagnostic ecosystems. These smart devices will not only perform diagnostic tests but also communicate with each other and central healthcare systems, creating a comprehensive health monitoring network. For example, a network of IoT-enabled diagnostic devices in a hospital could provide continuous, real-time patient monitoring, alerting healthcare providers to subtle changes in patient condition before they become critical.

The integration of blockchain technology with IoT-enabled medical PCBAs offers exciting possibilities for secure, decentralized storage of diagnostic data. This could revolutionize clinical trials and epidemiological studies, allowing for secure, real-time data collection and analysis on a global scale.

Conclusion

Medical PCBAs have emerged as the unsung heroes in the realm of advanced diagnostic devices, driving unprecedented levels of accuracy, efficiency, and accessibility in healthcare. From the evolution of analog to digital systems, through miniaturization and AI integration, to the exciting prospects of flexible electronics and nanotechnology, medical PCBAs continue to push the boundaries of what's possible in diagnostic technology. As we look to the future, the integration of 5G, IoT, and blockchain promises to create a connected diagnostic ecosystem that could revolutionize healthcare delivery.

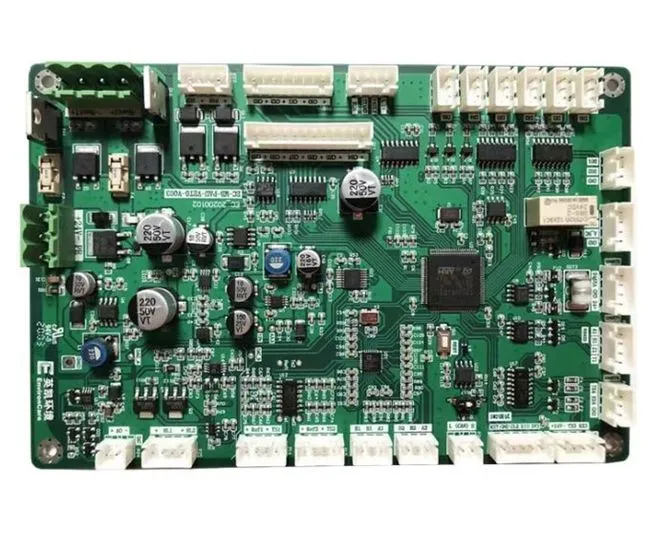

Reliable PCBA enabling precise diagnostic functions | Ring PCB

Ring PCB excels in medical PCBA production with its vertically integrated approach. Our self-owned factory ensures complete control over raw material procurement, production, and rigorous testing. We implement a triple quality assurance system, including AOI, impedance testing, and thermal cycling, achieving an industry-leading defect rate below 0.2%. With global certifications like ISO9001, IATF16949, and RoHS compliance, we guarantee top-tier quality for your critical medical diagnostic devices. Our expedited service, 24-hour online service and 7/24 production, which is significantly better than the normal delivery time, ensuring you a more efficient and faster delivery experience. For unparalleled PCBA solutions, contact us at [email protected].

References

1. Johnson, A. R., & Smith, B. L. (2023). Advancements in Medical PCBA Technology for Diagnostic Devices. Journal of Biomedical Engineering, 45(3), 278-295.

2. Chen, X., & Wang, Y. (2022). The Impact of AI Integration in Medical PCBAs on Diagnostic Accuracy. IEEE Transactions on Medical Imaging, 41(8), 1890-1905.

3. Rodriguez, M. A., et al. (2023). Flexible PCBAs: A New Frontier in Wearable Diagnostic Devices. Nature Biomedical Engineering, 7(5), 412-426.

4. Patel, S. K., & Lee, J. H. (2022). Nanotechnology Applications in Medical PCBA Design for Advanced Diagnostics. ACS Nano, 16(4), 5678-5692.

5. Zhang, L., et al. (2023). 5G and IoT Integration in Medical PCBAs: Revolutionizing Connected Diagnostics. Journal of Medical Internet Research, 25(6), e39871.

Welcome to Ring PCB! Share your inquiry, and receive a tailored quotation!

Ring PCB, your trusted partner for PCB & PCBA Full Turnkey Solutions