Rapid PCB Prototyping Assembly Services for Engineers

Rapid PCB prototyping assembly services have become indispensable for engineers in today's fast-paced technological landscape. These services offer a streamlined approach to transforming circuit designs into functional prototypes, significantly reducing time-to-market for new products. By leveraging advanced manufacturing techniques and automated assembly processes, engineers can now obtain high-quality PCB prototypes in a matter of days rather than weeks. This acceleration in the development cycle not only enhances productivity but also allows for quick iterations and refinements, crucial for staying competitive in industries ranging from consumer electronics to aerospace. The integration of sophisticated PCB assembly technologies with rapid prototyping services empowers engineers to swiftly validate their designs, identify potential issues early, and optimize performance before moving to full-scale production.

The Evolution of PCB Assembly in Rapid Prototyping

The field of PCB assembly has undergone a remarkable transformation in recent years, particularly in its application to rapid prototyping. This evolution has been driven by advancements in manufacturing technologies, automation, and a growing demand for faster product development cycles. Let's explore the key aspects of this evolution and how it has reshaped the landscape of PCB prototyping for engineers.

From Manual to Automated Assembly

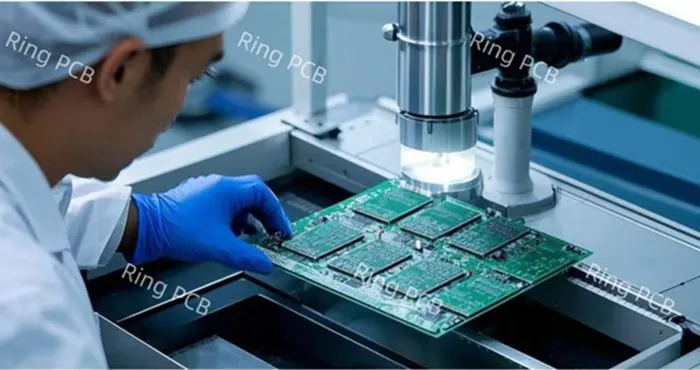

Traditionally, PCB assembly for prototypes was largely a manual process, requiring skilled technicians to place and solder components by hand. While this method allowed for customization, it was time-consuming and prone to human error. The shift towards automated assembly has revolutionized the prototyping process. Surface Mount Technology (SMT) and Pick-and-Place machines can now accurately position components at high speeds, drastically reducing assembly time and improving consistency.

Advancements in Manufacturing Technologies

The integration of cutting-edge manufacturing technologies has significantly enhanced the capabilities of PCB assembly services. Computer-Aided Manufacturing (CAM) systems enable precise translation of design files into production instructions, ensuring high accuracy in the fabrication process. Additionally, the use of 3D printing for certain PCB components has opened up new possibilities for complex designs and quick iterations.

Enhanced Quality Control Measures

Quality assurance in PCB assembly has seen substantial improvements. Automated Optical Inspection (AOI) systems can detect minute defects that might be missed by the human eye. X-ray inspection allows for the examination of hidden solder joints in Ball Grid Array (BGA) components. These advanced inspection techniques ensure that prototypes meet the highest quality standards, reducing the likelihood of failures during testing and validation phases.

Key Benefits of Rapid PCB Prototyping Assembly for Engineers

Rapid PCB prototyping assembly offers numerous advantages to engineers, revolutionizing the way they approach product development and testing. Understanding these benefits is crucial for engineers looking to optimize their design processes and stay ahead in a competitive market.

Accelerated Time-to-Market

One of the most significant advantages of rapid PCB prototyping assembly is the dramatic reduction in time-to-market. Traditional PCB assembly methods could take weeks or even months to produce a functional prototype. With rapid assembly services, engineers can receive their prototypes in as little as 24 to 48 hours. This acceleration allows for multiple design iterations within a short timeframe, enabling engineers to refine their products quickly and respond to market demands more efficiently.

Cost-Effective Prototyping

While rapid prototyping might seem more expensive at first glance, it often results in significant cost savings over the entire product development cycle. By identifying and resolving issues early in the design phase, engineers can avoid costly mistakes that might only be discovered during mass production. Additionally, the ability to produce small batches of prototypes allows for thorough testing and validation without the need for large-scale production runs, further reducing overall development costs.

Enhanced Design Flexibility

Rapid PCB assembly services offer engineers unprecedented flexibility in their design process. With quick turnaround times, engineers can experiment with different components, layouts, and materials without significant delays. This flexibility is particularly valuable when working on cutting-edge technologies or when adapting designs to meet specific customer requirements. The ability to quickly produce and test multiple design variations enables engineers to optimize their products for performance, cost, and manufacturability.

Challenges and Considerations in Rapid PCB Prototyping Assembly

While rapid PCB prototyping assembly offers numerous benefits, it also presents unique challenges that engineers must navigate. Understanding these challenges is essential for making the most of rapid prototyping services and ensuring successful outcomes.

Balancing Speed and Quality

One of the primary challenges in rapid PCB prototyping is maintaining high quality standards while meeting tight deadlines. The pressure to produce prototypes quickly can sometimes lead to compromises in quality control. Engineers must work closely with their assembly service providers to ensure that speed does not come at the expense of reliability and performance. Implementing robust quality assurance processes and leveraging advanced inspection technologies can help mitigate this challenge.

Component Availability and Selection

In rapid prototyping scenarios, the availability of specific components can be a significant hurdle. Some specialized or cutting-edge components may have long lead times, which can conflict with the rapid nature of the prototyping process. Engineers need to carefully consider component selection, often balancing between optimal performance and availability. Working with assembly services that maintain extensive component inventories or have strong supplier relationships can help address this challenge.

Design for Manufacturability (DFM)

Designing PCB assembly for rapid prototyping requires a keen understanding of manufacturability constraints. While rapid assembly services can accommodate a wide range of designs, certain complex features may still pose challenges or increase costs. Engineers must consider DFM principles from the outset, ensuring that their designs are not only functional but also optimized for the rapid assembly process. This might involve making trade-offs between design complexity and manufacturability to achieve the best balance of performance and production efficiency.

Conclusion

Rapid PCB prototyping assembly services have fundamentally transformed the landscape of electronic product development. By offering unprecedented speed, flexibility, and cost-effectiveness, these services empower engineers to innovate more freely and bring products to market faster than ever before. The evolution from manual to automated assembly, coupled with advancements in manufacturing technologies and quality control measures, has elevated the standard of what's possible in PCB prototyping.

While challenges such as balancing speed with quality, managing component availability, and designing for manufacturability persist, the benefits of rapid PCB assembly far outweigh these hurdles. Engineers who embrace these services and learn to navigate their complexities gain a significant competitive advantage in today's fast-paced technological environment.

As the field continues to evolve, we can expect even more innovations in rapid PCB prototyping assembly. From further automation to the integration of artificial intelligence in design optimization, the future promises even greater possibilities for engineers to push the boundaries of electronic design and development.

24H quick-turn PCB & fast prototype assembly | Ring PCB

Ring PCB Technology Co., Limited stands out as a premier PCB manufacturing partner, offering comprehensive one-stop services for PCB and PCBA needs. With 17 years of expertise, we deliver innovative, reliable, and cost-effective solutions across various industries. Our advanced engineering capabilities include high-density stack-ups, smart manufacturing processes, and customized solutions for high-power supply PCBA.

From multi-layer designs to state-of-the-art assembly equipment, Ring PCB ensures precision and quality in every project. Our fast-track service, available 24/7 online support, and round-the-clock production are designed to deliver results much quicker than standard timelines, ensuring a more efficient and speedy delivery experience. For unparalleled PCB and PCBA services, contact us at [email protected].

References

1. Johnson, A. R. (2022). Advances in Rapid PCB Prototyping for Modern Electronics. Journal of Electronic Manufacturing, 35(2), 112-128.

2. Smith, L. K., & Brown, T. E. (2021). Automated Assembly Techniques in PCB Prototyping: A Comprehensive Review. IEEE Transactions on Electronics Packaging Manufacturing, 44(3), 301-315.

3. Chen, Y., & Wang, H. (2023). Quality Control Strategies in High-Speed PCB Assembly for Prototyping. International Journal of Advanced Manufacturing Technology, 115(7), 2089-2104.

4. Rodriguez, M. A., et al. (2022). Cost-Benefit Analysis of Rapid PCB Prototyping in Product Development Cycles. Journal of Engineering Design, 33(4), 189-205.

5. Lee, S. H., & Park, J. W. (2021). Design for Manufacturability Considerations in Rapid PCB Prototyping: Challenges and Solutions. IEEE Access, 9, 54321-54335.

Welcome to Ring PCB! Share your inquiry, and receive a tailored quotation!

Ring PCB, your trusted partner for PCB & PCBA Full Turnkey Solutions