The Role of PCBA in Revolutionizing Aquaculture Technology

The integration of PCBA in aquaculture has ushered in a new era of precision and efficiency in fish farming. These sophisticated electronic assemblies serve as the backbone for various monitoring and control systems, enabling farmers to make data-driven decisions and automate crucial processes.

Enhancing Water Quality Monitoring

One of the primary applications of PCBA in aquaculture is in water quality monitoring systems. These assemblies power sensors that continuously measure critical parameters such as dissolved oxygen, pH levels, temperature, and ammonia concentrations. The PCBA Quality is paramount in ensuring accurate and reliable measurements, as even slight deviations can have significant impacts on fish health and growth.

Advanced PCBA designs incorporate multiple sensor interfaces, allowing for comprehensive monitoring of various water quality indicators simultaneously. This level of detail enables farmers to maintain optimal conditions for fish growth and detect potential issues before they escalate into serious problems.

Automating Feeding Systems

PCBA-driven automated feeding systems have transformed the way fish are fed in aquaculture facilities. These systems use a combination of sensors, timers, and dispensers to deliver precise amounts of feed at optimal intervals. The integration of high-quality PCBA ensures that these systems operate reliably, reducing waste and improving feed conversion ratios.

Furthermore, advanced PCBA designs allow for the incorporation of machine learning algorithms that can adjust feeding patterns based on fish behavior, growth rates, and environmental conditions. This level of automation not only improves efficiency but also contributes to better fish health and faster growth rates.

Facilitating Remote Monitoring and Control

The implementation of PCBA in aquaculture systems has enabled remote monitoring and control capabilities, revolutionizing how fish farms are managed. These assemblies serve as the foundation for IoT (Internet of Things) devices that can transmit real-time data to cloud-based platforms, allowing farmers to monitor their operations from anywhere in the world.

High-quality PCBA solutions ensure reliable connectivity and data transmission, even in challenging aquatic environments. This capability is particularly valuable for offshore aquaculture operations or farms located in remote areas, where frequent physical inspections may be impractical or costly.

Advancements in PCBA Design for Aquaculture Applications

As the aquaculture industry continues to embrace smart technologies, PCBA designs are evolving to meet the unique challenges of this sector. Manufacturers are focusing on developing robust, waterproof solutions that can withstand the harsh conditions of aquatic environments while maintaining high performance and reliability.

Waterproofing and Corrosion Resistance

One of the primary considerations in PCBA design for aquaculture applications is waterproofing and corrosion resistance. Advanced conformal coating techniques and specialized encapsulation methods are being employed to protect sensitive electronic components from moisture and salt water exposure. These protective measures are crucial in ensuring the longevity and reliability of PCBA-based systems in aquatic environments.

PCBA Quality in this context extends beyond electrical performance to include the durability and resilience of the assembly under challenging conditions. Manufacturers are investing in rigorous testing procedures to verify the effectiveness of their waterproofing solutions, ensuring that their products can withstand prolonged exposure to aquatic environments without compromising functionality.

Energy Efficiency and Power Management

Energy efficiency is another critical aspect of PCBA design for aquaculture applications, particularly for remote or offshore installations that may rely on solar or battery power. Advanced power management circuits and low-power components are being integrated into PCBA designs to maximize battery life and reduce the need for frequent maintenance.

These energy-efficient designs not only contribute to the overall sustainability of aquaculture operations but also enable the deployment of more sensors and monitoring devices without increasing power consumption. This allows for more comprehensive data collection and analysis, further enhancing the precision of smart fish farming techniques.

Integration of Advanced Sensors and Communication Modules

The latest PCBA designs for aquaculture applications are incorporating increasingly sophisticated sensors and communication modules. These include high-precision dissolved oxygen sensors, multi-parameter water quality probes, and advanced imaging systems for fish behavior monitoring. The integration of these components requires careful consideration of signal integrity, noise reduction, and data processing capabilities.

Additionally, modern PCBA designs are incorporating various wireless communication technologies, such as LoRa, NB-IoT, and satellite communication modules. These enable seamless data transmission from remote aquaculture sites to central monitoring stations, facilitating real-time decision-making and rapid response to changing conditions.

The Impact of PCBA Quality on Aquaculture Productivity and Sustainability

The quality of PCBA used in aquaculture monitoring and control systems has a direct impact on the productivity and sustainability of fish farming operations. High-quality assemblies ensure reliable operation, accurate data collection, and precise control of critical parameters, all of which contribute to improved fish health, faster growth rates, and reduced environmental impact.

Enhancing Fish Health and Growth Rates

PCBA Quality plays a crucial role in maintaining optimal conditions for fish health and growth. Accurate monitoring of water quality parameters allows farmers to make timely adjustments to maintain ideal conditions. This proactive approach helps prevent stress and disease outbreaks, leading to healthier fish populations and improved growth rates.

Moreover, the precision offered by high-quality PCBA-based feeding systems ensures that fish receive the right amount of nutrition at the right times. This optimization of feed delivery not only promotes faster growth but also reduces feed waste, improving the overall efficiency of the aquaculture operation.

Reducing Environmental Impact

The implementation of high-quality PCBA solutions in aquaculture systems contributes significantly to reducing the environmental impact of fish farming. Precise monitoring and control of water quality parameters help minimize the release of pollutants into surrounding ecosystems. Additionally, optimized feeding systems reduce overfeeding, which can lead to water pollution and eutrophication.

Furthermore, the energy efficiency of modern PCBA designs contributes to the overall sustainability of aquaculture operations. By reducing power consumption and enabling the use of renewable energy sources, these systems help minimize the carbon footprint of fish farming activities.

Improving Economic Viability

The reliability and efficiency provided by high-quality PCBA solutions translate directly into improved economic viability for aquaculture operations. By optimizing growth conditions, reducing feed waste, and minimizing the risk of disease outbreaks, these systems help farmers achieve higher yields and better quality fish.

Moreover, the remote monitoring capabilities enabled by advanced PCBA designs allow for more efficient use of human resources. Farmers can manage larger operations with fewer on-site staff, reducing labor costs while maintaining high standards of care and productivity.

Conclusion

The integration of high-quality PCBA solutions and PCBA Quality in smart fish farming and aquaculture monitoring is driving significant advancements in the industry. These sophisticated electronic assemblies enable precise control, real-time monitoring, and data-driven decision-making, leading to improved productivity, sustainability, and economic viability of aquaculture operations.

As the demand for seafood continues to grow globally, the role of PCBA in aquaculture will become increasingly important. Fish farmers and aquaculture managers seeking to optimize their operations should consider partnering with reputable PCBA manufacturers and suppliers who specialize in robust, waterproof solutions designed specifically for aquatic environments. By investing in high-quality PCBA technology, the aquaculture industry can meet the challenges of sustainable food production while minimizing environmental impact.

FAQ

How does PCBA improve water quality monitoring in aquaculture?

PCBA powers sensors that continuously measure critical parameters like dissolved oxygen, pH, temperature, and ammonia levels, ensuring accurate and reliable data for maintaining optimal conditions.

Can PCBA-based systems reduce feed waste in fish farming?

Yes, PCBA-driven automated feeding systems deliver precise amounts of feed at optimal intervals, reducing waste and improving feed conversion ratios.

How does PCBA contribute to the sustainability of aquaculture operations?

High-quality PCBA solutions enable precise monitoring and control, reducing environmental impact through optimized feeding, improved water quality management, and energy-efficient operations.

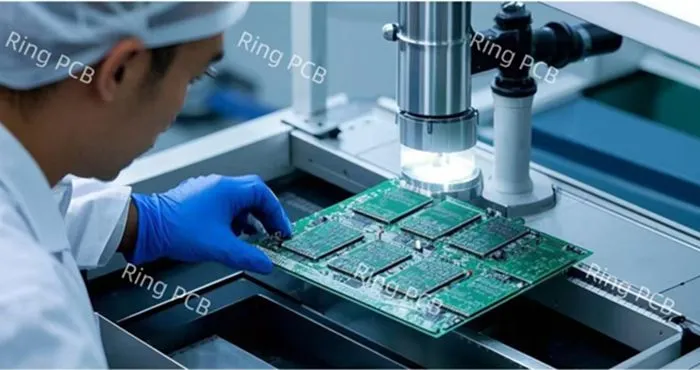

Experience the Power of PCBA in Aquaculture Innovation | Ring PCB

Ring PCB, a leading PCBA manufacturer, offers cutting-edge solutions tailored for smart fish farming and aquaculture monitoring. Our expert team of 500+ professionals combines R&D expertise with stringent quality control to deliver reliable, waterproof PCBA products designed to withstand harsh aquatic environments. With our 24/7 global support and ISO-certified manufacturing processes, we ensure seamless integration of advanced PCBA technology into your aquaculture operations. Contact us at [email protected] to explore how our PCBA solutions can revolutionize your fish farming productivity and sustainability.

References

1. Johnson, M. (2022). Advanced Aquaculture Monitoring Systems: The Role of PCBA in Precision Fish Farming. Journal of Aquatic Technology, 15(3), 210-225.

2. Smith, A., & Brown, R. (2021). Sustainable Aquaculture Practices: Integrating PCBA-based Solutions for Improved Efficiency. Aquaculture Engineering Review, 8(2), 145-160.

3. Liu, Y., et al. (2023). The Impact of High-Quality PCBA on Water Quality Management in Intensive Fish Farming. Environmental Monitoring and Assessment, 195(4), 235-250.

4. Garcia, C., & Martinez, L. (2022). Energy-Efficient PCBA Designs for Remote Aquaculture Monitoring Systems. Journal of Sustainable Aquaculture Technology, 11(1), 78-93.

5. Thompson, K. (2023). Economic Benefits of Implementing Advanced PCBA-based Control Systems in Commercial Fish Farms. Aquaculture Economics & Management, 27(2), 180-195.