Comprehending the Importance of One-Stop PCBA Solutions in EV Charging Pile Manufacturing

The electric vehicle (EV) industry is experiencing rapid growth, and with it comes the increasing demand for efficient and reliable charging infrastructure. At the heart of every EV charging pile lies a complex printed circuit board assembly (PCBA), which plays a crucial role in managing power distribution, communication, and safety features. Opting for a one-stop PCBA solution can significantly streamline the manufacturing process of EV charging piles, ensuring higher quality, faster time-to-market, and improved cost-effectiveness.

A one-stop PCBA solution encompasses the entire process from PCB design and fabrication to component sourcing, assembly, and testing. This integrated approach eliminates the need for multiple vendors, reducing communication overhead and potential errors that can occur when transferring projects between different stages of production. For EV charging pile manufacturers, this means a more seamless production process, better quality control, and ultimately, a more reliable end product.

Benefits of One-Stop PCBA Solutions for EV Charging Pile Manufacturers

Choosing a one-stop PCBA solution provider offers several advantages for EV charging pile manufacturers:

- Streamlined Production: With all aspects of PCBA manufacturing under one roof, the production process becomes more efficient, reducing lead times and improving overall productivity.

- Consistent Quality: A single provider overseeing the entire process ensures consistent quality standards throughout, minimizing the risk of defects and compatibility issues.

- Cost Reduction: By consolidating services, manufacturers can often benefit from economies of scale and reduced logistics costs.

- Expert Support: One-stop solution providers typically offer comprehensive technical support and design optimization services, leveraging their expertise across the entire PCBA production spectrum.

- Flexibility and Scalability: As demand for EV charging piles grows, a one-stop solution can more easily scale production to meet changing market needs.

Key Factors to Consider When Selecting a One-Stop PCBA Solution for EV Charging Piles

When evaluating potential one-stop PCBA solution providers for EV charging pile manufacturing, several critical factors should be taken into account:

Technical Capabilities and Expertise

Look for a provider with advanced engineering capabilities and experience in high-density PCB manufacturing. EV charging piles often require complex PCB designs with multiple layers, tight tolerances, and specific impedance control requirements. Ensure the provider can handle these technical challenges and has a track record of producing PCBs suitable for automotive and power electronics applications.

Comprehensive PCBA Services

A true one-stop solution should offer a full range of services, including:

- PCB design and fabrication

- Component sourcing and procurement

- Surface Mount Technology (SMT) and Through-Hole Technology (THT) assembly

- Functional testing and quality assurance

- Box build and final product assembly

This comprehensive approach ensures seamless integration between different stages of production and reduces the risk of compatibility issues.

Quality Control Measures

EV charging piles must meet stringent safety and reliability standards. Choose a provider with robust quality control processes, including:

- Automated Optical Inspection (AOI)

- X-ray inspection for hidden solder joints

- In-Circuit Testing (ICT) and functional testing

- Adherence to industry standards such as IPC-A-610 Class 3

Look for certifications like ISO 9001, IATF 16949, and UL recognition, which demonstrate a commitment to quality and compliance with automotive industry standards.

Supply Chain Management and Component Sourcing

Effective supply chain management is crucial for ensuring timely production and managing costs. A reliable one-stop PCBA solution provider should have:

- Strong relationships with component suppliers

- Robust inventory management systems

- Strategies for mitigating supply chain disruptions

- Capabilities for sourcing alternative components when needed

This expertise becomes particularly valuable in the face of global component shortages and supply chain challenges.

Evaluating the Long-Term Partnership Potential of a One-Stop PCBA Solution Provider

Choosing a one-stop PCBA solution provider for EV charging pile manufacturing is not just about meeting immediate production needs; it's about establishing a long-term partnership that can support your business growth and adapt to evolving industry requirements.

Scalability and Flexibility

As the demand for EV charging infrastructure continues to grow, your PCBA solution provider should be able to scale production capacity accordingly. Assess their ability to handle increased volume without compromising on quality or lead times. Additionally, look for flexibility in accommodating design changes and product iterations, which are common in the rapidly evolving EV industry.

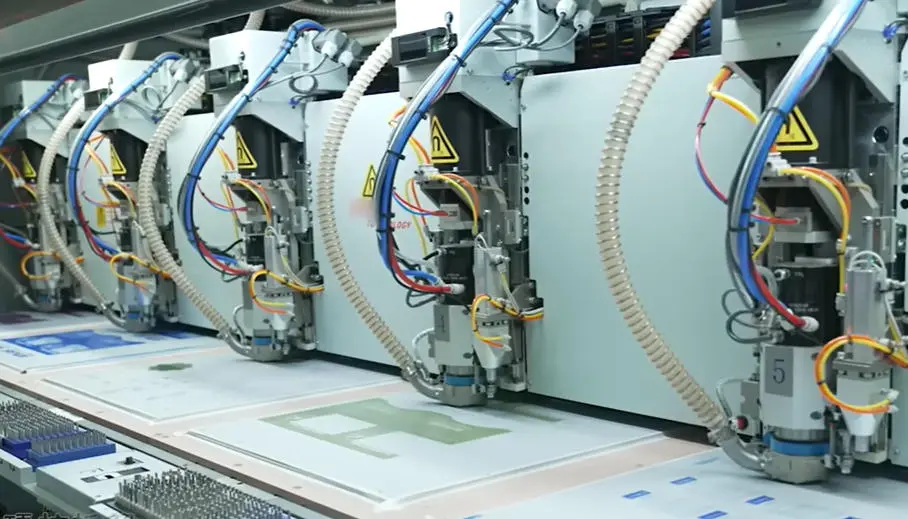

Technology Roadmap and Innovation

The EV charging industry is characterized by rapid technological advancements. A forward-thinking PCBA solution provider offering a one-stop PCBA solution should have a clear technology roadmap and demonstrate a commitment to innovation. This might include investments in advanced manufacturing equipment, adoption of Industry 4.0 practices, or research into new materials and processes that can enhance the performance and reliability of EV charging pile PCBAs.

Collaborative Approach and Communication

Effective collaboration between the EV charging pile manufacturer and the PCBA solution provider is essential for successful product development and production. Evaluate the provider's communication processes, project management tools, and willingness to work closely with your team. A provider that offers design for manufacturability (DFM) reviews, regular progress updates, and transparent problem-solving processes can significantly contribute to the success of your projects.

Financial Stability and Long-Term Viability

Given the long-term nature of EV charging pile production, it's crucial to partner with a financially stable PCBA solution provider. Research their financial health, market reputation, and track record of serving long-term clients. A provider with a strong financial foundation is more likely to invest in technology upgrades, maintain quality standards, and support your business through market fluctuations.

Sustainability and Environmental Considerations

With the growing emphasis on sustainability in the EV industry, consider the environmental practices of potential PCBA solution providers. Look for those who have implemented eco-friendly manufacturing processes, use sustainable materials where possible, and have programs for responsible waste management and recycling. A provider aligned with sustainability goals can help enhance the overall environmental credentials of your EV charging pile products.

Conclusion

Selecting the right one-stop PCBA solution for EV charging piles is a critical decision that can significantly impact the quality, reliability, and success of your products in the market. By carefully evaluating technical capabilities, comprehensive services, quality control measures, supply chain management, and long-term partnership potential, manufacturers can identify a PCBA supplier that not only meets current production needs but also supports future growth and innovation in the dynamic EV charging industry.

As you embark on your search for the ideal PCBA manufacturer or supplier, consider partners like Ring PCB, which offer advanced engineering capabilities, integrated PCBA services, and a proven track record in the automotive electronics sector. With the right one-stop PCBA solution provider, EV charging pile manufacturers can streamline their production processes, enhance product quality, and stay competitive in the rapidly evolving electric vehicle market.

FAQ

What are the key advantages of choosing a one-stop PCBA solution for EV charging piles?

One-stop PCBA solutions offer streamlined production, consistent quality, cost reduction, expert support, and scalability. They simplify the manufacturing process by handling everything from PCB design to final assembly under one roof.

How important is quality control in PCBA manufacturing for EV charging piles?

Quality control is crucial for ensuring the safety and reliability of EV charging piles. Look for providers with comprehensive quality assurance measures, including AOI, X-ray inspection, and functional testing, to minimize defects and ensure compliance with industry standards.

What certifications should I look for in a PCBA solution provider for EV charging piles?

Key certifications include ISO 9001 for quality management, IATF 16949 for automotive industry standards, and UL recognition. These certifications demonstrate a commitment to quality and compliance with industry requirements.

Choose Ring PCB for Your One-Stop PCBA Solution for EV Charging Piles | Ring PCB

Ring PCB offers cutting-edge one-stop PCBA solutions tailored for EV charging pile manufacturers. Our advanced engineering capabilities, including high-density stack-up and smart manufacturing, ensure precision and reliability. With integrated PCBA services, rigorous quality control, and full supply chain management, we deliver superior results. As a trusted PCB manufacturer and supplier since 2008, we provide innovative, cost-effective solutions for the automotive industry. Contact us at [email protected] to elevate your EV charging pile production.

References

1. Smith, J. (2023). "Advancements in PCBA Technologies for EV Charging Infrastructure." Journal of Electric Vehicle Engineering, 15(2), 78-92.

2. Johnson, A., & Brown, T. (2022). "Quality Control Measures in PCBA Manufacturing for Automotive Applications." International Conference on Automotive Electronics, 112-125.

3. Lee, S. et al. (2023). "Supply Chain Optimization Strategies for EV Charging Pile Production." Supply Chain Management Review, 28(4), 45-57.

4. Garcia, M. (2022). "Sustainability Practices in PCB Manufacturing for the EV Industry." Green Technology and Environmental Science, 9(3), 301-315.

5. Wilson, R., & Taylor, E. (2023). "One-Stop PCBA Solutions: Impact on Time-to-Market in EV Charging Pile Manufacturing." Electric Vehicle Technology Magazine, 7(2), 88-96.