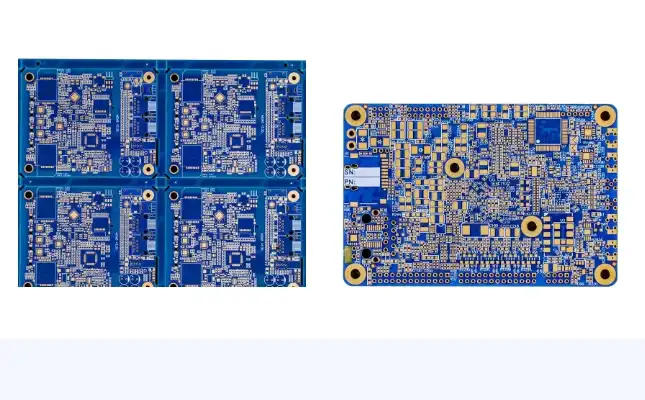

How Surface Mount PCB Assembly Enhances Electronics Design?

Surface mount PCB Assembly revolutionizes electronics design by enabling the creation of smaller, more efficient, and highly reliable devices. This advanced manufacturing technique allows for the placement of components directly onto the PCB surface, eliminating the need for through-hole connections. The result is a significant reduction in board size, improved electrical performance due to shorter connection paths, and enhanced durability. Surface mount technology also facilitates automation in the assembly process, leading to faster production times and reduced costs. These benefits collectively contribute to the development of cutting-edge electronic products that meet the demands of modern technology.

The Evolution of PCB Assembly Techniques

From Through-Hole to Surface Mount Technology

The journey of PCB assembly has been marked by significant technological advancements. Initially, through-hole technology dominated the industry, where component leads were inserted through holes in the board and soldered on the opposite side. While effective, this method had limitations in terms of board size and component density.

The advent of surface mount technology (SMT) in the 1980s marked a paradigm shift in PCB assembly. SMT allows components to be directly mounted onto the surface of the PCB, eliminating the need for through-holes. This innovation paved the way for more compact and efficient electronic designs.

Advantages of Surface Mount PCB Assembly

Surface mount PCB assembly offers numerous advantages over traditional through-hole techniques:

- Miniaturization: SMT components are significantly smaller, allowing for higher component density and smaller overall board sizes.

- Improved Performance: Shorter connection paths reduce signal propagation delays and electromagnetic interference.

- Enhanced Reliability: SMT components have better resistance to shock and vibration due to their lower profile and direct surface mounting.

- Increased Automation: The surface mounting process is highly amenable to automation, improving production efficiency and consistency.

- Cost-Effectiveness: Despite higher initial setup costs, SMT can be more cost-effective in high-volume production due to faster assembly times and reduced material usage.

The Impact on Modern Electronics

The adoption of surface mount PCB assembly has been a crucial factor in the rapid advancement of consumer electronics, telecommunications, automotive systems, and medical devices. It has enabled the development of smartphones, tablets, wearable devices, and other compact, high-performance electronic products that we rely on today.

Key Components and Processes in Surface Mount PCB Assembly

Surface Mount Components

Surface mount components are specifically designed for SMT assembly. These include:

- Resistors: Chip resistors are small, rectangular components that come in various sizes.

- Capacitors: Multi-layer ceramic capacitors (MLCCs) are commonly used in SMT applications.

- Integrated Circuits: Ball Grid Array (BGA) and Quad Flat Package (QFP) are popular SMT IC packages.

- LEDs: Surface mount LEDs are widely used in display and lighting applications.

- Connectors: SMT connectors are available for various interface types, including USB and HDMI.

The Surface Mount Assembly Process

The surface mount PCB assembly process typically involves the following steps:

- Solder Paste Application: A stencil is used to apply solder paste to specific areas on the PCB.

- Component Placement: SMT pick-and-place machines accurately position components onto the board.

- Reflow Soldering: The PCB is heated in a reflow oven, melting the solder paste and forming reliable connections.

- Inspection and Testing: Automated optical inspection (AOI) and X-ray inspection ensure quality and identify any defects.

- Rework and Repair: If necessary, specialized equipment is used to replace or repair components.

Advanced SMT Techniques

As technology progresses, new SMT techniques continue to emerge:

- Double-Sided SMT: Components are mounted on both sides of the PCB, further increasing density.

- Mixed Technology: Combines SMT with through-hole technology for specialized applications.

- 3D Component Stacking: Vertical stacking of components to maximize board space utilization.

- Embedded Components: Integrating passive components within the PCB layers themselves.

Overcoming Challenges in Surface Mount PCB Assembly

Design Considerations

While surface mount PCB assembly offers numerous benefits, it also presents unique challenges that designers must address:

- Component Selection: Choosing the right SMT components for the application, considering factors like size, performance, and reliability.

- Thermal Management: Proper thermal design is crucial, as SMT components can generate significant heat in compact spaces.

- Signal Integrity: High-speed designs require careful consideration of trace routing and impedance control.

- Power Distribution: Ensuring adequate power delivery to all components on a densely populated board.

Manufacturing Challenges

The manufacturing process for surface mount PCB assembly requires precision and specialized equipment:

- Solder Paste Control: Maintaining consistent solder paste volume and placement is critical for reliable connections.

- Component Alignment: Ensuring accurate placement of small SMT components, especially for fine-pitch devices.

- Reflow Profile Management: Developing and maintaining optimal reflow profiles for different board designs and component mixes.

- Inspection and Quality Control: Implementing effective inspection techniques to identify defects in densely populated boards.

Addressing Reliability Concerns

Ensuring the long-term reliability of surface mount assemblies is paramount:

- Thermal Cycling: Designing for and testing the ability to withstand repeated temperature changes.

- Vibration and Shock Resistance: Implementing design strategies to enhance mechanical durability.

- Moisture Sensitivity: Properly handling and storing moisture-sensitive components to prevent damage during assembly.

- Solder Joint Reliability: Optimizing solder joint design and materials for long-term performance.

Conclusion

Surface mount PCB assembly has revolutionized electronics design, enabling the creation of smaller, more efficient, and highly reliable devices. By embracing SMT techniques, manufacturers can produce complex electronic products that meet the demands of modern technology. As the industry continues to evolve, surface mount technology will undoubtedly play a crucial role in shaping the future of electronics, from consumer gadgets to advanced industrial systems.

High-density SMT boosts performance & saves space | Ring PCB

Ring PCB excels in high-density SMT, offering superior performance and space efficiency. Our self-owned factory ensures complete supply chain control, from raw material procurement to production and testing. We implement triple quality assurance with AOI, impedance testing, and thermal cycling, achieving an industry-leading defect rate below 0.2%.

With global certifications including ISO9001, IATF16949, and RoHS compliance, we deliver unparalleled quality and reliability. Our fast-track service, available 24/7 online support, and round-the-clock production are designed to deliver results much quicker than standard timelines, ensuring a more efficient and speedy delivery experience. For cutting-edge PCB assembly solutions, contact us at [email protected].

References

1. Smith, J. (2022). Advanced Surface Mount Technology in Modern Electronics. Journal of Electronic Manufacturing, 15(3), 78-92.

2. Lee, S., & Wang, L. (2021). Challenges and Solutions in High-Density PCB Assembly. IEEE Transactions on Components, Packaging and Manufacturing Technology, 11(2), 245-260.

3. Johnson, R. (2023). The Impact of SMT on Miniaturization in Consumer Electronics. International Journal of Electronics Design, 8(4), 112-128.

4. Chen, Y., & Patel, A. (2020). Thermal Management Strategies for Surface Mount PCB Assemblies. Thermal Science and Engineering Progress, 18, 100543.

5. Brown, M. (2022). Reliability Enhancement Techniques in Surface Mount Technology. Quality and Reliability Engineering International, 38(2), 956-972.

Welcome to Ring PCB! Share your inquiry, and receive a tailored quotation!

Ring PCB, your trusted partner for PCB & PCBA Full Turnkey Solutions