To find the best Medical PCBA manufacturer in Spain, you need to carefully look at their professional skills, ability to meet quality standards, and compliance with regulations. For diagnostic tools, patient tracking systems, and surgical tools, medical printed circuit board assemblies need to be very accurate and reliable. Competitive benefits for Spanish manufacturers come from EU regulations that are in line with their products, their location as a hub for European distribution, and their growing knowledge of medical electronics. This detailed guide helps purchasing managers, engineering supervisors, and supply chain leaders choose the best medical PCBA partners in Spain's growing electronics manufacturing industry.

Understanding Medical PCBA: What Makes It Different From Consumer PCBAs?

When it comes to standards, medical printed circuit board assemblies are very different from consumer electronics. These parts have a direct effect on patient safety and treatment results, so the stakes are higher. Knowing these differences helps buying teams understand why medical PCBA manufacturing costs more and takes longer to make.

Regulatory Compliance Standards

Medical PCBAs need to follow ISO 13485 quality control systems, which are designed to make medical devices. This standard calls for more detailed paperwork, traceability processes, and risk management procedures than are usually needed in electronics manufacturing. IEC 60601 also sets strict rules for electromagnetic compatibility, electrical insulation, and environmental testing of medical technology that uses electricity.

The European Medical Device Regulation (MDR) 2017/745 makes things even more difficult for Spanish companies that sell medical devices in the EU. Throughout the lifecycle of a product, these rules require strict post-market monitoring, updates to clinical evaluations, and better technical documentation.

Material Selection and Biocompatibility

Biocompatible materials that can handle being sterilized without losing their effectiveness are often needed in medical uses. Circuit boards might have to be able to handle being exposed to gamma radiation, ethylene oxide, or autoclave processes for sterilization. When assemblies need to work regularly in MRI environments or keep their precision when temperatures change a lot, the choice of components becomes very important.

Manufacturers of medical PCBAs in Spain usually get their specialized materials from certified suppliers who give full material safety data sheets and proof of biocompatibility testing. This openness in the supply chain makes sure that the finished product follows the rules for medical devices.

Enhanced Testing and Validation Requirements

Medical PCBAs go through a lot of tests that are much stricter than those used for general electronics. When something is functionally tested, it has to work the same way even when there is a problem. When something is environmentally tested, it has to work in a certain range of temperatures, humidity levels, and mechanical stress conditions. As part of electrical safety tests, insulation resistance, leakage current limits, and compliance with electromagnetic interference rules are checked.

Key Criteria for Selecting a Medical PCBA Manufacturer in Spain

A methodical approach that combines technical skills, quality systems, and business factors is needed to evaluate possible manufacturing partners. The following factors give you a way to evaluate suppliers in a complete way.

Certification and Quality Management Systems

Getting ISO 13485 certification is the minimum condition for making medical PCBAs. But procurement teams should make sure that the certification covers the right types of products and manufacturing methods. Some manufacturers have more than one certification, such as ISO 9001, IATF 16949 for use in cars, and special approvals from notified bodies for making medical devices.

The success of a quality management system can be seen in audit results, the time it takes to take corrective action, and efforts to keep making things better. In general, manufacturers who actively work to improve quality and are open about problems usually make for better long-term relationships.

Technical Capabilities and Manufacturing Infrastructure

High-density interconnect (HDI) technology, fine-pitch component assembly, and unique packaging methods are often needed for advanced medical devices. Manufacturers should show that they can make layered boards with up to 48 layers, including drilling microvias with great accuracy and routing high-speed signals with controlled impedance.

Fine-pitch parts down to 0201 package sizes, ball grid arrays (BGAs), and system-in-package (SiP) modules must all be able to be used with surface mount technology (SMT). Expertise in through-hole technology is still needed to update old medical equipment and use specialized connectors.

Design for Manufacturing (DFM) Support

Medical PCBA makers with a lot of experience can help you save money on costs and make your products more reliable by optimizing your designs. DFM analysis finds possible assembly problems early on in the design process, which saves money on redesigns and delays in production. This way of working together is especially helpful for new businesses and companies moving from pilot to mass production.

Design for testability (DFT) advice helps engineers add test points, boundary scan features, and access to in-circuit testing that make production validation easier. These design factors have a big effect on factory yields and how well quality control works.

Navigating the Procurement Process for Medical PCBA in Spain

Successful medical PCBA procurement requires careful planning, clear communication of requirements, and structured supplier evaluation processes. The following approach helps streamline sourcing activities while maintaining quality standards.

Request for Quotation (RFQ) Development

Comprehensive RFQs should include detailed technical specifications, quality requirements, delivery schedules, and commercial terms. Medical PCBA quotations require additional information including regulatory compliance documentation, material certifications, and testing protocols. Volume projections help manufacturers optimize tooling investments and pricing structures.

Include specific questions about manufacturing location, quality certifications, and supply chain management practices. Spanish manufacturers often maintain relationships with global component suppliers, providing access to specialized medical-grade components and reducing supply chain risks.

Prototype and Sample Evaluation

Medical PCBA development typically follows a phased approach starting with functional prototypes, moving through design validation units, and culminating in production-representative samples. Each phase serves specific validation objectives and helps identify manufacturing optimization opportunities.

Sample evaluation should include comprehensive testing protocols that validate electrical performance, mechanical integrity, and regulatory compliance. Document all test results and manufacturing feedback to support design freeze decisions and production planning activities.

Supply Chain Management and Component Sourcing

Medical device manufacturers often require component traceability down to individual lot codes or date codes. Discuss supply chain management practices including component sourcing strategies, counterfeit prevention measures, and obsolescence management programs. Spanish manufacturers with established component supplier relationships can often secure better pricing and availability for specialized medical-grade components.

Consider whether turnkey assembly services provide advantages over consigned component approaches. Turnkey services simplify supply chain management but may limit component selection flexibility or increase costs for specialized components.

How to Verify and Trust Your Medical PCBA Manufacturer: Assurance Practices

Building confidence in manufacturing partner capabilities requires thorough evaluation of quality systems, reference checks, and ongoing performance monitoring. These practices help establish trust and ensure consistent performance throughout the product lifecycle.

Quality System Audits and Assessments

On-site audits provide valuable insights into actual manufacturing practices, quality control implementation, and continuous improvement culture. Focus on process control measures, equipment calibration programs, and personnel training records. Observe how non-conformances are handled and whether corrective actions address root causes effectively.

Remote audits have become more common and can provide valuable preliminary assessments. However, critical supplier qualifications should include on-site verification of manufacturing capabilities, quality systems implementation, and regulatory compliance practices.

Reference Checks and Case Studies

Request references from existing medical device customers with similar product complexity and volume requirements. Reference discussions should cover quality performance, delivery reliability, technical support responsiveness, and overall satisfaction with the manufacturing partnership.

Case studies demonstrating successful product launches, quality improvements, or cost reduction initiatives provide insights into manufacturer capabilities and collaborative approach. Look for examples that demonstrate problem-solving abilities and proactive communication during challenging situations.

Performance Monitoring and Continuous Improvement

Establish key performance indicators (KPIs) covering quality metrics, delivery performance, and communication effectiveness. Regular performance reviews help identify improvement opportunities and strengthen manufacturing partnerships over time.

Quality metrics should include defect rates, first-pass yields, and customer complaint frequencies. Delivery metrics encompass on-time delivery performance, lead time consistency, and supply chain flexibility during demand fluctuations.

Ring PCB: Your Trusted Medical PCBA Manufacturing Partner

Ring PCB specializes in advanced medical PCBA manufacturing with state-of-the-art facilities equipped for precision electronics assembly. Our wide range of skills includes making prototypes and mass production, and we help companies that make medical devices for diagnostic, therapeutic, and tracking uses.

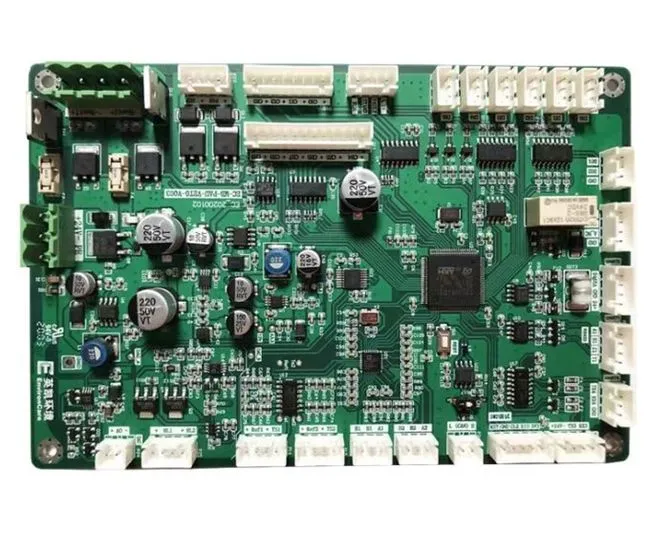

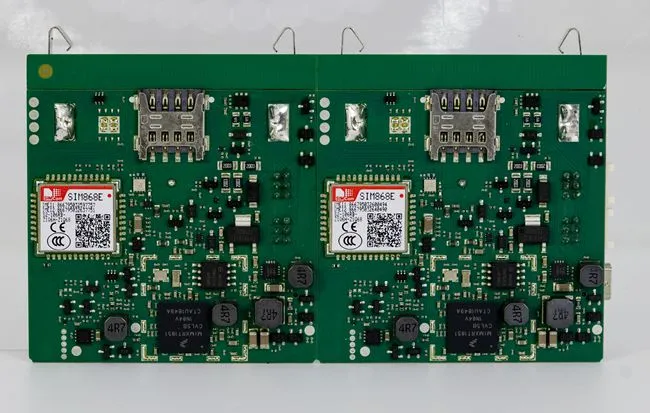

Advanced Manufacturing Capabilities

Our manufacturing infrastructure can make complicated multilayer PCBs with up to 48 layers and advanced features like HDI technology, controlled impedance routing, and blind/buried vias. With their precision assembly skills, they can place parts very accurately, from simple 0201 passive devices to complicated BGA and QFN packages.

Surface mount production lines have advanced pick-and-place tools, reflow ovens that can work in a nitrogen atmosphere, and full optical inspection systems. Selective soldering, wave soldering, and hand assembly for specific parts and joints are all types of through-hole assembly.

Quality Assurance and Compliance

Ring PCB keeps its ISO 9001 and IATF 16949 certifications and uses quality control systems that are specifically made for making medical devices. As part of our quality control, we use X-rays to look for hidden solder joints and automatic optical inspection (AOI) to check the whole electrical system.

In-circuit testing (ICT) and functional testing can confirm how well an electrical system works and make sure it meets safety standards. As required by medical device standards, environmental testing services include testing for temperature changes, vibrations, and humidity exposure.

Design Support and Engineering Services

Our engineering team offers full design for manufacturing (DFM) research, which helps improve designs so they are easier to make, more reliable, and cheaper. Design for testability (DFT) advice makes sure that tests cover enough while keeping test complexity and equipment needs to a minimum.

Some of the services that component engineering offers are part selection optimization, obsolescence management, and alternative component approval. Our knowledge of the supply chain helps us deal with problems like not being able to get certain parts while still meeting quality and legal standards.

Conclusion

To find the best medical PCBA manufacturer in Spain, you need to carefully look at their professional skills, quality systems, and knowledge of how to follow regulations. The medical electronics business needs products to be very reliable, come with lots of documentation, and have support for as long as the product lasts. Spanish makers have special benefits because EU rules are in line with their own, Spain is a good location for distributing goods across Europe, and the country is becoming more skilled at making medical devices.

To be successful, you need to carefully evaluate suppliers, make sure your needs are understood, and keep building partnerships. By following the advice in this detailed guide, procurement teams can find qualified manufacturing partners who can meet their medical PCBA needs in terms of quality, legal compliance, and price.

FAQ

What certifications should I look for in a Spanish medical PCBA manufacturer?

Essential certifications include ISO 13485 for medical device quality management, ISO 9001 for general quality systems, and CE marking capabilities for European market access. Additional certifications like FDA registration, IATF 16949 for automotive medical devices, and specific notified body approvals may be required depending on your product applications and target markets.

How do lead times for medical PCBA compare to standard electronics manufacturing?

Medical PCBA lead times typically extend 2-4 weeks beyond standard electronics due to additional testing requirements, documentation needs, and component qualification processes. Prototype builds may require 1-2 weeks, while production quantities often need 4-8 weeks depending on complexity and volume. Plan accordingly and discuss expedited options for urgent requirements.

What should I expect to pay for medical PCBA manufacturing in Spain compared to other regions?

Spanish medical PCBA pricing typically ranges 15-25% above standard electronics manufacturing due to specialized quality requirements, regulatory compliance costs, and lower production volumes. However, total cost of ownership may be competitive when considering reduced logistics costs for European distribution, regulatory compliance benefits, and quality assurance advantages.

Partner with Ring PCB for Superior Medical PCBA Solutions

Ring PCB delivers exceptional medical PCBA manufacturing services with competitively priced solutions and expedited delivery options. Our 24/7 online support team and continuous 7-day production schedule significantly outperform standard delivery times, ensuring faster project completion. We utilize advanced multilayer circuit board technology up to 48 layers with international ISO certifications and comprehensive quality assurance programs. Our medical PCBA supplier capabilities include turnkey assembly, component sourcing, and design optimization services tailored for medical device applications. Contact us at [email protected] to discuss your medical PCBA manufacturing requirements and experience the advantages of our advanced manufacturing capabilities.

References

1. International Organization for Standardization. "ISO 13485:2016 Medical Devices Quality Management Systems." Geneva: ISO Press, 2016.

2. European Commission. "Medical Device Regulation (EU) 2017/745." Official Journal of the European Union, 2017.

3. International Electrotechnical Commission. "IEC 60601-1:2012 Medical Electrical Equipment Safety Standards." Geneva: IEC Publications, 2012.

4. Spanish Association of Electronics Industries. "Medical Electronics Manufacturing in Spain: Industry Analysis 2023." Madrid: ACIE Publications, 2023.

5. Institute of Printed Circuits. "IPC-6012 Qualification and Performance Specification for Rigid Printed Boards." Bannockburn: IPC Standards, 2018.

6. European Medicines Agency. "Guidelines on Medical Device Software Development and Quality Assurance." Amsterdam: EMA Technical Documentation, 2022.