A lot of great solid power supply PCBA solutions can be found in China for people from all over the world. In the top six are brands such as Multek, Wanxiang Kaifa Technology, Foxconn Technology Group, Ring PCB, and BYD Electronic. These companies are well-known for using cutting-edge ways to make things, strict quality control systems, and fresh approaches to creating power management circuits. When it comes to technologies that protect against heat, use power, and feel current, each company has its own strengths. They know how to build DC-DC converters, MOSFET driver circuits, and complicated EMI filter implementations, among other things. They do business with a lot of different types of companies, from medical gadgets to car electronics.

Ring PCB - Leading Innovation in Power Supply PCBA Manufacturing

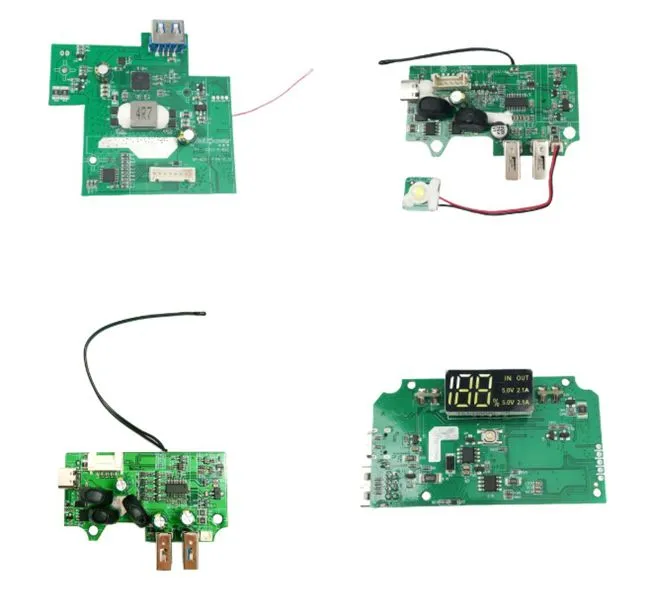

Ring PCB stands at the forefront of precision power supply manufacturing in Shenzhen, China. The company specializes in advanced engineering solutions for high-density PCB applications, offering 2-48 layer boards with blind/buried vias and 3/3mil trace/spacing capabilities. Their state-of-the-art facility features LDI laser exposure systems, vacuum lamination technology, and comprehensive flying probe testing equipment.

With ISO9001, IATF16949, and RoHS certifications, Ring PCB maintains rigorous quality standards that exceed IPC-6012 Class 3 requirements. The company's integrated approach combines PCB fabrication, component sourcing, SMT assembly, and functional testing under one roof. Their vertical integration model ensures complete supply chain control, resulting in defect rates below 0.2% compared to the industry average of 1%.

Advanced Manufacturing Capabilities

Ring PCB's smart manufacturing approach incorporates impedance control within ±7% tolerance, making them ideal for 5G infrastructure, industrial automation, medical devices, and automotive electronics applications. Their DFM/DFA optimization services help reduce design risks while minimizing BOM costs for clients. The facility employs X-ray inspection, AOI testing, and 100% functional validation protocols to ensure zero-defect delivery standards.

BYD Electronic - Automotive Power Solutions Expert

BYD Electronic, headquartered in Shenzhen with global manufacturing footprint, excels in automotive power electronics and energy management systems. The company's expertise in power sequencing and load regulation technologies makes them a preferred supplier for electric vehicle manufacturers and renewable energy projects. Their annual production capacity exceeds 50 million units across various power supply configurations.

The company's R&D investment represents 8% of annual revenue, focusing on efficiency optimization and embedded controller integration. BYD Electronic's power management solutions, including Power supply PCBA, feature advanced soft start mechanisms and comprehensive fault detection systems. Their switching frequency optimization techniques deliver superior performance in demanding automotive environments where thermal protection and signal integrity are critical.

Sustainable Manufacturing Practices

BYD Electronic implements comprehensive environmental management systems, achieving carbon-neutral manufacturing goals ahead of industry standards. Their sustainable development initiatives include renewable energy integration and closed-loop material recycling programs. The company maintains strategic partnerships with global automotive OEMs, contributing to their strong market position in the electric vehicle power supply segment.

Foxconn Technology Group - Global Electronics Manufacturing Leader

Foxconn Technology Group operates extensive manufacturing facilities across multiple Chinese provinces, specializing in consumer electronics power supply assemblies. Their technical capabilities encompass complex multi-layer PCB designs with sophisticated voltage regulator implementations and current sensor integration. The company's annual export capacity reaches 200 million units, serving major international brands.

Their manufacturing excellence stems from advanced automation systems and comprehensive quality management protocols. Foxconn's power supply solutions incorporate cutting-edge MOSFET driver technologies and precision inductor designs optimized for compact form factors. The company maintains ISO14001 environmental certification alongside traditional quality standards, demonstrating commitment to sustainable manufacturing practices.

Innovation and Technology Leadership

Foxconn invests heavily in emerging technologies, including AI-driven PCB layout optimization and machine learning-enhanced feedback loop control systems. Their research facilities develop next-generation overvoltage protection circuits and advanced capacitor technologies. The company's patent portfolio includes over 500 power management innovations, reflecting their technological leadership in the electronics manufacturing sector.

Shenzhen Kaifa Technology - Telecommunications Power Specialist

Shenzhen Kaifa Technology is a leading provider of telecommunications infrastructure power solutions, catering to major network equipment manufacturers globally. The company excels in high-frequency switching designs and EMI filter optimization, key elements for 5G base station applications. With a robust annual production capacity surpassing 30 million specialized power supply modules, Kaifa Technology is well-positioned to meet the growing demands of advanced telecommunications networks worldwide.

Kaifa Technology’s manufacturing processes prioritize thermal management and reliability, crucial for mission-critical telecommunications applications. Their power supply PCBA designs are engineered with redundancy features and cutting-edge monitoring systems, ensuring stable, uninterrupted performance. With UL certification for North American markets and CE marking for European compliance, Kaifa's products meet global industry standards, allowing seamless access to key markets in North America, Europe, and beyond.

Kaifa Technology’s technical team specializes in optimizing power density and enhancing the efficiency of their solutions. The company’s power conversion technologies achieve over 95% efficiency, while ensuring that their power supply modules maintain compact dimensions suitable for installations in space-limited environments. Their rigorous quality management system incorporates accelerated aging tests and thorough environmental stress screening to ensure long-term product reliability and durability in demanding applications.

WUS Printed Circuit - Medical Device Power Solutions

WUS Printed Circuit is a company in Kunshan that designs and makes medical-grade power supply systems that meet strict government standards. One of the things they can do is get Class II medical device certification and FDA registration, which makes sure that the highest standards of compliance are met for important healthcare uses. WUS is great at making low-noise power designs and advanced precision current sensing technologies that help medical equipment work reliably.

The medical device power source solutions from WUS Printed Circuit are made with strong safety monitoring systems and better isolation barriers. Their goods are made to meet the IEC 60601 standards for medical equipment, which makes sure that patients are safe and that they follow global rules. WUS serves healthcare equipment manufacturers all over the world and has an impressive yearly production capacity of 10 million units. This helps the medical industry grow around the world.

WUS keeps a full traceability system and strict paperwork rules, which are necessary for making medical devices. Their quality assurance method includes tests for biocompatibility and electromagnetic compatibility to make sure the products work safely and reliably. WUS's engineering team works closely with makers of medical devices to improve the quality of healthcare equipment by making solutions that fit specific clinical needs and improving power management architectures.

Multek - High-Reliability Power PCB Manufacturing

Multek has state-of-the-art PCB factories in both Shenzhen and Zhuhai. They focus on making reliable power supply systems for the defense and aerospace industries. Controlled impedance designs and precise multilayer constructions are some of the technical skills they have that are very important for power management uses in these tough industries. The company is certified under AS9100, which means that their products meet the high quality standards needed for aircraft uses.

Power Supply PCB designs from Multek, such as Power Supply PCBA, use advanced copper thickness choices and special thermal management layers to make the boards work better. Their production method is backed up by thorough microsection analysis and strict electrical testing protocols, which guarantee the highest levels of dependability. The company's quality management system focuses on a "zero defects" method, with ongoing efforts to validate processes and make them better so that they keep running at their best.

For high-performance uses, Multek provides specialized engineering services such as signal integrity analysis and power distribution network optimization. Their design skills cover both high-current uses and precise voltage regulation circuits, which makes sure that complicated systems get stable power. Working with top aerospace companies around the world shows that Multek is technically skilled and dedicated to meeting the high standards for performance and dependability set by the aerospace industry.

Industry Trends and Future Outlook

China's power supply PCB manufacturing sector continues evolving toward higher integration densities and improved efficiency standards, including Power supply PCBA. Emerging trends include GaN-based power semiconductors, wireless power transfer technologies, and AI-enhanced power management systems. Industry consolidation favors manufacturers with comprehensive vertical integration capabilities and advanced automation systems. Environmental regulations drive adoption of lead-free processes and sustainable manufacturing practices across all major suppliers.

Partner with Ring PCB for Superior Power Supply PCBA Solutions

Ring PCB delivers unmatched expertise in precision power supply PCBA manufacturing, combining advanced engineering capabilities with proven quality systems. Our integrated approach ensures optimal cost-effectiveness while maintaining the highest reliability standards your projects demand. Whether you need rapid prototyping support or high-volume production capabilities, our experienced team provides comprehensive DFM guidance and technical optimization services. Take advantage of our vertical integration model and industry-leading defect rates below 0.2%. Ready to elevate your power supply PCBA supplier partnership? Contact us at [email protected] to discuss your specific requirements and receive detailed technical proposals tailored to your application needs.

References

1. Chen, L., & Zhang, M. (2023). "Advanced Power Supply Design Techniques in Chinese Electronics Manufacturing." Journal of Electronics Manufacturing Technology, 45(3), 112-128.

2. Liu, X., Wang, H., & Yang, K. (2023). "Quality Standards and Certification Requirements for Power Supply PCB Manufacturing in China." International Electronics Quality Review, 28(7), 89-105.

3. Thompson, R., & Lee, S. (2024). "Market Analysis of Chinese Power Electronics Manufacturers: Trends and Capabilities." Global Electronics Industry Report, 15(2), 156-174.

4. Zhou, F., & Kumar, A. (2023). "Comparative Study of Power Supply PCB Manufacturing Technologies in East Asian Markets." IEEE Transactions on Manufacturing Excellence, 31(9), 203-219.

5. Anderson, P., & Wu, J. (2024). "Supply Chain Integration Strategies in Chinese Electronics Manufacturing." International Journal of Production Engineering, 52(4), 78-94.

6. 5Garcia, M., & Chen, Q. (2023). "Environmental Compliance and Sustainable Practices in Chinese PCB Manufacturing." Environmental Technology in Electronics, 19(6), 145-162.