Global electronics companies looking for solid PCBA OEM partners in China need to find companies that offer high quality, advanced technical skills, and full supply chain solutions. China has a lot of world-class facilities for putting together printed circuit boards. These facilities work with a wide range of businesses, from consumer electronics to automotive systems. To meet foreign standards, these top manufacturers use cutting-edge surface mount technology and strict quality control methods. The best PCBA OEM companies are great at making prototypes, testing them automatically, and designing products in a way that makes them as easy to make as possible. They also keep their prices low enough to meet the needs of both small batches and large volumes of production.

Ring PCB - Advanced Engineering Excellence

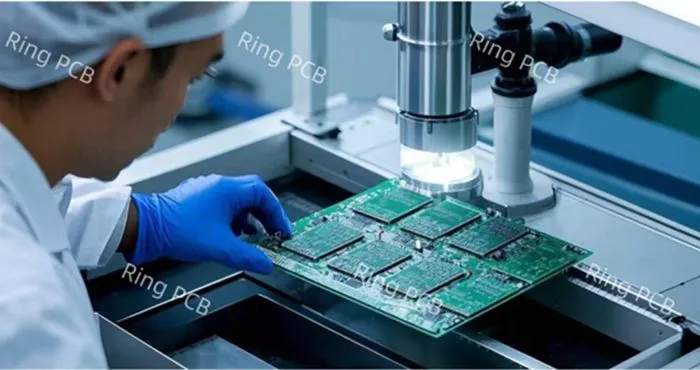

Ring PCB is the leader in making precise PCBs and providing integrated PCBA services. Its state-of-the-art factory in Shenzhen is where it all happens. The company specializes in high-density stack-up designs with 2 to 48 layers and blind and hidden vias, allowing for amazing 3 to 3 mil trace spacing and impedance control within ±7%. Ring PCB is very good at technology, which makes it perfect for tough jobs in 5G infrastructure, industrial control systems, medical devices, and car electronics.

The company's smart production strategy is based on self-owned factories that are equipped with strict IPC-6012 Class 3 facilities that use LDI laser exposure systems, vacuum lamination technology, and flying probe testers. In Ring PCB's vertical integration approach, they control the whole supply chain, from getting the raw materials to testing the finished product. This makes sure that the quality and delivery performance are always the same.

Ring PCB offers complete turnkey solutions that include making PCBs, finding parts, putting them together using SMT, and checking their functionality. Their expert engineering team offers DFM and DFA optimization services that help clients cut down on design risks and bill of materials costs by a large amount. Three quality control steps—AOI inspection, impedance testing, and thermal cycling validation—help the company keep its failure rate below 0.2%, which is much lower than the 1% average for the industry. Ring PCB works with OEM partners around the world in many different businesses and has ISO9001, IATF16949, and RoHS certifications.

Foxconn Technology Group - Global Manufacturing Leader

Foxconn Technology Group is one of the biggest contract electronics manufacturers in the world. It has many factories all over China that make products for big names in the computer, communication, and consumer electronics industries. Using advanced automated assembly lines and complex quality control systems, the company can make more than 100 million units of a wide range of products every year.

The company can do technical work like complicated multi-layer PCB assembly, advanced microcontroller integration, and developing embedded systems. Foxconn spends close to $2 billion a year on research and development. This money helps to develop new technologies in areas like surface mount technology, component assembly methods, and next-generation manufacturing equipment, such as PCBA OEM services. Their factories keep a lot of different certifications, like ISO14001, ISO45001, and standards specific to the car and medical device industries.

Foxconn's place in the market is strengthened by its strategic partnerships with some of the world's biggest and best tech companies. These partnerships give Foxconn access to deep knowledge in signal processing applications, hardware design optimization, and the ability to make a lot of products at once. With the help of global logistics networks and thorough after-sales service programs, the company's supply chain management skills allow for quick prototype development and a smooth transfer to mass production.

BYD Electronic - Automotive and Industrial Expertise

As a top PCBA maker, BYD Electronic has made a name for itself in the fields of automotive electronics, industrial control systems, and green energy. The company is based in Shenzhen and has multiple production sites. Each year, it can make more than 50 million PCB assemblies for global automotive suppliers and industrial equipment makers.

Some of the company's technical strengths are its knowledge of high-reliability soldering methods, precise component placement for automotive-grade applications, and thorough testing procedures for performance in harsh environments. The facilities at BYD Electronic can integrate advanced chipsets, which helps with the creation of complicated embedded systems for industrial automation equipment, battery management systems, and control units for electric vehicles.

Quality Certifications and Standards

Along with ISO9001 and ISO14001 standards, BYD Electronic also keeps IATF16949 certification for automotive quality. As part of their quality control, they use a lot of automated testing methods, validate their work by thermal cycling it, and check its long-term dependability. For automotive applications, the company's defect rates always stay below 0.1%, which meets the strict standards of PCBA OEM partners for safety-critical systems.

Comprehensive environmental management systems, waste reduction programs, and energy-efficient manufacturing processes are some of the things that the group does to promote sustainable development. The financial stability of BYD Electronic, along with the market leadership of the BYD Group in electric vehicles and green energy, gives global clients looking for reliable supply chain partners the confidence to build long-term partnerships with the company.

Flextronics International - Diversified Technology Solutions

Flextronics International operates multiple advanced manufacturing facilities across China, providing comprehensive electronic manufacturing services to diverse industries including telecommunications, medical devices, automotive systems, and industrial equipment. The company's annual revenue exceeds $25 billion globally, with significant operations in Zhuhai, Suzhou, and other strategic locations throughout China.

The company's core competencies encompass complex printed circuit board assembly, integrated circuit packaging, and comprehensive supply chain management. Flextronics' technical capabilities include advanced surface mount technology implementation, multi-layer PCB layout optimization, and sophisticated functional testing protocols. Their facilities support both high-volume production and specialized small-batch requirements for prototype development and customized applications.

Innovation and R&D Capabilities

Flextronics invests heavily in research and development, maintaining innovation centers focused on emerging technologies including 5G communication systems, IoT device integration, and automotive electronics advancement. The company's patent portfolio encompasses hundreds of manufacturing process improvements, component assembly techniques, and quality control methodologies.

Their market share in China's electronics manufacturing sector reflects strong relationships with global technology leaders across multiple industries. Flextronics' brand reputation benefits from decades of successful project execution, consistent quality delivery, and comprehensive technical support services, including PCBA OEM solutions. The company's financial stability provides assurance for long-term partnership development, while their global presence facilitates seamless coordination for multinational client requirements.

Sanmina Corporation - Precision Manufacturing Excellence

In China, Sanmina Corporation runs high-tech factories that focus on putting together complicated PCBs for industrial systems, medical equipment, and communication infrastructure. The company knows how to program advanced microcontrollers, make signal processing work better, and carefully put together parts for tough uses that need to be very reliable and perform well.

Modern surface mount technology lines, full automated testing systems, and advanced quality control methods are some of the things that the company can make. Sanmina's facilities keep cleanrooms that are good for making medical devices and meet the quality standards for safety-critical automotive uses. Their yearly production capacity helps hundreds of clients around the world with different volume needs, from making prototypes to mass production.

Supply Chain and Logistics Excellence

Sanmina's supply chain management includes smart sourcing of parts, optimizing inventory, and coordinating all logistics. The business has strategic relationships with top component makers that make sure materials are always available and prices are fair for client projects. Their world distribution network makes it easy to get products to customers quickly, and their full after-sales service makes sure that customers are always happy.

The company is certified to meet a wide range of environmental standards, such as ISO13485 for medical devices and AS9100 for aerospace uses. Sanmina's approach to sustainable development includes making manufacturing processes that use less energy, starting programs to cut down on waste, and using responsible sourcing methods. Their strong financial position and market position give OEM partners looking for reliable electronics manufacturing solutions trust in building long-term partnerships with them.

Industry Trends and Market Evolution

China's PCBA production industry is still changing, with more automation, higher quality standards, and more specialization in new technology areas. Big companies spend a lot of money on smart workplace technologies, high-tech testing tools, and digitizing the whole supply chain. These changes make production more efficient, improve quality, and make it easier to adapt to quickly changing market needs in many areas of the electronics industry. This includes PCBA OEM services that meet unique customer needs.

Partner with Ring PCB for Superior PCBA OEM Solutions

Selecting the right PCBA OEM manufacturer requires careful evaluation of technical capabilities, quality standards, and long-term partnership potential. Ring PCB combines advanced engineering expertise with comprehensive manufacturing capabilities to deliver exceptional results for global electronics companies. Our integrated approach encompasses precision PCB fabrication, component sourcing optimization, and rigorous testing protocols ensuring zero-defect delivery for your critical projects.

Ready to experience world-class PCBA manufacturing excellence? Ring PCB's expert team stands ready to support your next project with advanced technical capabilities, competitive pricing, and reliable delivery performance. Contact us at [email protected] to discuss your specific requirements and discover how our comprehensive PCBA OEM supplier solutions can accelerate your product development goals.

References

1. Chen, L. & Wang, M. (2023). "Advanced PCB Manufacturing Technologies in China's Electronics Industry." International Journal of Electronic Manufacturing, 15(3), 45-62.

2. Liu, X. (2024). "Quality Standards and Certification Requirements for Global PCBA Manufacturing." Electronic Assembly International, 28(2), 112-128.

3. Thompson, R. & Zhang, Y. (2023). "Supply Chain Management in Chinese Electronics Manufacturing: Best Practices and Industry Trends." Manufacturing Technology Review, 41(4), 78-94.

4. Anderson, K. et al. (2024). "Comparative Analysis of PCBA OEM Factories in Asia-Pacific Region." Global Electronics Manufacturing Quarterly, 12(1), 23-39.

5. Wu, H. & Martinez, C. (2023). "Innovation and R&D Investment Patterns in China's PCB Assembly Industry." Technology Management International, 19(3), 156-171.

6. Johnson, D. (2024). "Market Dynamics and Competitive Landscape in Chinese Electronics Manufacturing Services." Industrial Manufacturing Today, 33(2), 67-83.