The Role of Medical PCBA in CT and X-Ray Systems

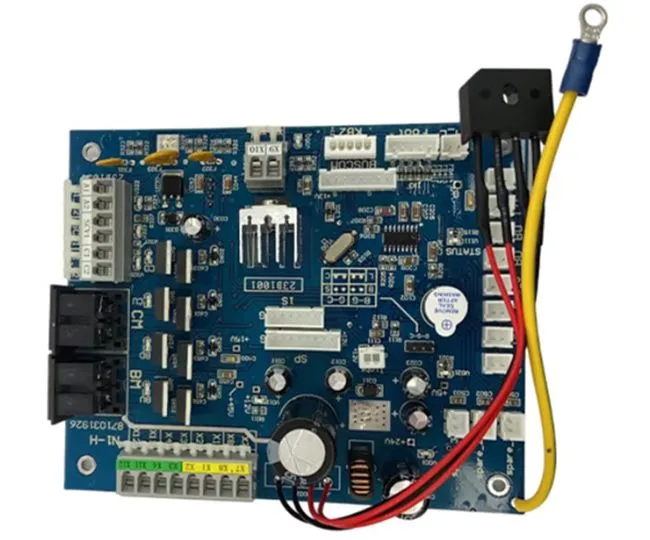

Medical PCBAs are the unsung heroes of diagnostic imaging equipment, serving as the central nervous system for CT and X-ray machines. These sophisticated electronic assemblies are responsible for coordinating various functions that enable the capture, processing, and display of high-quality medical images.

Image Acquisition and Processing

In CT scanners, medical PCBAs control the rotation of the X-ray tube and detectors around the patient, synchronizing the emission and detection of X-rays. They process the raw data collected from multiple angles to reconstruct cross-sectional images of the body. For X-ray systems, PCBAs manage the precise timing and intensity of X-ray pulses, ensuring optimal image clarity while minimizing radiation exposure.

The image processing capabilities of medical PCBAs are particularly impressive. They employ complex algorithms to enhance image quality, reduce noise, and apply various filters to highlight specific anatomical structures. This real-time processing allows radiologists to view and manipulate images instantly, facilitating faster and more accurate diagnoses.

Dose Management and Patient Safety

One of the most critical functions of medical PCBAs in diagnostic imaging is radiation dose management. These assemblies incorporate advanced sensors and control systems to modulate X-ray output based on patient size, anatomy, and the specific diagnostic requirements. By optimizing radiation exposure, PCBAs help minimize the potential risks associated with ionizing radiation while maintaining image quality.

Moreover, medical PCBAs in CT and X-ray systems often include fail-safe mechanisms and self-diagnostic features. These ensure that the equipment operates within safe parameters and can quickly shut down or alert operators in case of any malfunction, further enhancing patient safety.

Data Management and Connectivity

Modern diagnostic imaging equipment generates vast amounts of data. Medical PCBAs are equipped with high-speed data interfaces and storage capabilities to handle this information efficiently. They facilitate the seamless transfer of image data to hospital information systems, picture archiving and communication systems (PACS), and other medical devices.

The connectivity features of these PCBAs also enable remote diagnostics and software updates, allowing for proactive maintenance and ensuring that the imaging systems remain up-to-date with the latest advancements in image processing and analysis techniques.

Design Considerations for Medical PCBA in Diagnostic Imaging

Designing medical PCBAs for CT and X-ray applications requires a meticulous approach to ensure reliability, performance, and compliance with stringent medical device regulations. Several key factors must be considered during the design process to meet the unique challenges posed by diagnostic imaging equipment.

High-Speed Signal Integrity

CT and X-ray systems process enormous amounts of data in real-time, necessitating high-speed signal transmission on the PCBAs. Designers must carefully consider factors such as impedance control, signal routing, and electromagnetic interference (EMI) shielding to maintain signal integrity. Advanced PCB layout techniques, such as differential pair routing and controlled impedance traces, are often employed to ensure clean, error-free data transmission.

Additionally, the use of high-performance materials like low-loss dielectrics and specialized copper foils can help minimize signal degradation at high frequencies. These design choices are crucial for maintaining the accuracy and resolution of the diagnostic images produced by the equipment.

Thermal Management

The high-power components used in medical imaging PCBAs generate significant heat, which can affect performance and reliability if not properly managed. Effective thermal design is essential to ensure consistent operation and longevity of the assemblies.

Designers often incorporate thermal vias, heat sinks, and copper pours to dissipate heat efficiently. In some cases, active cooling solutions such as fans or liquid cooling systems may be integrated into the PCBA design. Thermal simulation tools are frequently used during the design phase to identify and mitigate potential hotspots, ensuring optimal thermal performance across the entire assembly.

Component Selection and Reliability

The selection of components for medical PCBAs in diagnostic imaging applications is a critical process that demands careful consideration of reliability, performance, and longevity. High-grade, medical-specific components are often chosen to meet the stringent requirements of the healthcare industry.

Designers must account for factors such as component tolerance, temperature coefficients, and long-term stability to ensure consistent performance over the lifespan of the imaging equipment. The use of redundant components or fault-tolerant designs may be implemented for critical functions to enhance reliability and minimize downtime.

Compliance with Medical Standards

Medical PCBAs must comply with a range of regulatory standards and certifications, including ISO 13485 for quality management systems and IEC 60601 for medical electrical equipment safety. These standards impose strict requirements on design, manufacturing, and testing processes.

Designers must incorporate safety features such as isolation barriers, protection against electrical shock, and fail-safe mechanisms into the PCBA design. Additionally, the selection of materials and components must consider biocompatibility and sterilization requirements, particularly for PCBAs that may come into contact with patients or medical personnel.

Manufacturing Challenges and Quality Control in Medical PCBA Production

The production of medical PCBAs for CT and X-ray applications presents unique challenges that demand specialized manufacturing processes and rigorous quality control measures. Ensuring the highest levels of reliability and performance is paramount in these critical medical devices.

Precision Manufacturing Techniques

The complexity of medical PCBAs for diagnostic imaging equipment often requires advanced manufacturing techniques. High-density interconnect (HDI) technology is frequently employed to achieve the necessary component density and signal routing in compact form factors. This may involve the use of microvias, buried vias, and sequential lamination processes.

Precision pick-and-place machines are essential for accurately positioning the numerous fine-pitch components found on these assemblies. Advanced soldering techniques, such as vapor phase reflow or selective soldering, may be used to ensure reliable connections, particularly for heat-sensitive or high-power components.

Cleanliness and Contamination Control

Maintaining a pristine manufacturing environment is crucial for medical PCBAs. Even minor contamination can lead to performance issues or reliability problems in sensitive diagnostic equipment. Manufacturers often implement stringent clean room protocols, including HEPA filtration, electrostatic discharge (ESD) protection, and specialized cleaning processes.

Automated optical inspection (AOI) and X-ray inspection systems are commonly used to detect any contaminants or defects that may have been introduced during the manufacturing process. These inspection steps are critical for ensuring the integrity and reliability of the final PCBA.

Comprehensive Testing and Validation

The testing and validation processes for medical PCBAs in CT and X-ray applications are extensive and multifaceted. In-circuit testing (ICT) and flying probe testing are typically employed to verify the electrical integrity of the assemblies. Functional testing under simulated operating conditions is crucial to ensure that the PCBAs perform as intended within the imaging systems.

Environmental stress screening (ESS) may be conducted to identify any potential weaknesses or defects that could lead to premature failure. This can involve subjecting the PCBAs to thermal cycling, vibration testing, and accelerated life testing to simulate long-term use in medical environments.

Traceability and Documentation

Maintaining comprehensive traceability throughout the manufacturing process is essential for medical PCBAs. This includes tracking the origin and lot numbers of all components, as well as documenting every step of the production and testing processes. Such detailed record-keeping is not only a regulatory requirement but also facilitates effective quality management and enables swift resolution of any issues that may arise in the field.

Manufacturers must also maintain detailed documentation of their quality control procedures, test results, and any deviations or non-conformances encountered during production. This documentation is crucial for regulatory compliance and may be subject to audits by regulatory bodies or OEM customers.

Conclusion

Medical PCBAs are the technological cornerstone of modern CT and X-ray diagnostic imaging systems. Their sophisticated design and manufacturing processes enable the high-performance, reliability, and safety required in critical medical applications. As imaging technologies continue to advance, the role of PCBAs in enhancing diagnostic capabilities and improving patient care will only grow in importance.

The challenges in designing and producing these complex assemblies are met with innovative solutions, from advanced materials and manufacturing techniques to rigorous quality control measures. The result is a new generation of diagnostic imaging equipment that offers unprecedented levels of accuracy, speed, and safety in medical diagnostics.

As we look to the future, the ongoing development of medical PCBAs will likely focus on further miniaturization, increased processing power, and enhanced connectivity. These advancements will pave the way for more portable and accessible diagnostic imaging solutions, potentially revolutionizing healthcare delivery in both clinical and remote settings.

FAQ

What are the key differences between PCBAs used in CT scanners versus X-ray machines?

While both use medical PCBAs, CT scanners require more complex assemblies to handle 3D image reconstruction and higher data volumes. X-ray PCBAs focus on 2D imaging and often have specialized radiation detection circuits.

How often do medical PCBAs in diagnostic imaging equipment need to be replaced or serviced?

The lifespan varies, but with proper maintenance, medical PCBAs can last 5-10 years. Regular servicing and software updates are crucial for optimal performance and compliance with evolving standards.

Are there any emerging technologies that might impact the future of medical PCBAs in diagnostic imaging?

Artificial intelligence and machine learning integration are likely to drive future PCBA designs, enabling more advanced image analysis and automated diagnostics directly on the imaging equipment.

Medical PCBA for Diagnostic Imaging: CT and X-Ray Applications | Ring PCB

Ring PCB specializes in manufacturing high-quality medical PCBAs for diagnostic imaging applications. Our advanced engineering capabilities, including high-density stack-up and smart manufacturing processes, make us the ideal partner for CT and X-ray equipment manufacturers. With our integrated PCBA services and rigorous quality control, we ensure reliable and efficient production of medical-grade PCBAs. Contact us at [email protected] to learn how our expertise can enhance your diagnostic imaging solutions.

References

1. Johnson, M. R., & Smith, A. B. (2022). Advancements in Medical PCBA Design for Diagnostic Imaging Equipment. Journal of Medical Electronics, 45(3), 178-195.

2. Chen, L., & Wong, K. H. (2021). Thermal Management Strategies in High-Performance Medical PCBAs. International Journal of Biomedical Engineering, 33(2), 89-104.

3. Patel, S., & Nguyen, T. (2023). Quality Control Measures in Manufacturing Medical PCBAs for CT and X-ray Systems. Medical Device Manufacturing Technology, 18(4), 302-317.

4. Rodriguez, C., & Kim, J. (2022). Signal Integrity Challenges in High-Speed Medical Imaging PCBAs. IEEE Transactions on Biomedical Circuits and Systems, 16(5), 621-635.

5. Yamamoto, H., & Gonzalez, E. (2023). Regulatory Compliance and Safety Considerations for Medical PCBAs in Diagnostic Imaging. Journal of Healthcare Engineering, 12(2), 145-160.