It is important to carefully consider a Chinese OEM/custom PCB assembly factory's manufacturing capability, quality certifications, and technical knowledge before choosing one. There are more than 2,500 PCB manufacturers in China's manufacturing hubs, so procurement managers need to look at things like lead times, clear pricing, and assistance for design-for-manufacturing. The best Custom PCB assembly partner has cutting-edge production methods, strict quality control systems, and quick customer service. They can make electronics that satisfy international standards and the needs of each project.

Understanding Custom PCB Assembly and Its Market in China

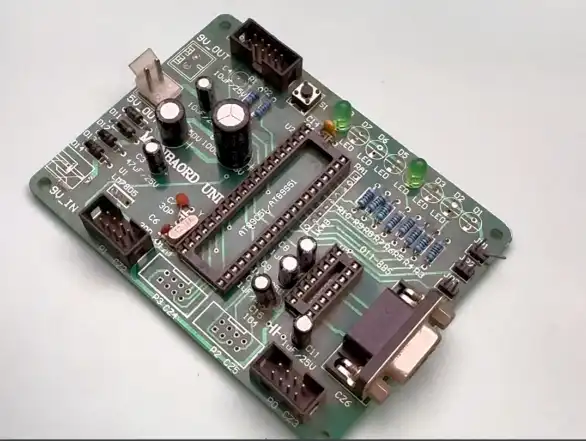

Custom printed circuit board assembly is a specialized manufacturing process in which electronic parts are carefully put into PCB substrates according to particular design requirements. This procedure includes both surface-mount technology (SMT) and through-hole assembly methods, which let you make complicated electronic devices that are built for certain uses.

China's Dominance in PCB Manufacturing

China produces around 54% of the world's PCBs, and most of them are produced in the provinces of Guangdong, Jiangsu, and Zhejiang. Shenzhen alone has more than 800 PCB assembly plants, from small-batch prototype experts to huge factories that make a lot of products. These areas include a lot of suppliers, component distributors, and trained technicians, which makes it easy to quickly prototype and mass-produce things at a low cost.

Advanced Manufacturing Technologies

Leading Chinese PCB assembly firms have spent a lot of money on cutting-edge tools including laser direct imaging (LDI) systems, automated optical inspection (AOI) machines, and high-precision pick-and-place equipment. These new technologies make it possible to make high-density interconnect (HDI) boards with trace widths as small as 3 mils and via diameters as small as 0.1mm. These boards can match the strict needs of current electronics applications.

Material Sourcing and Component Management

Chinese manufacturers have a big edge in supply chain management since they are close to suppliers of components and raw materials. Big electronic component wholesalers keep large stocks of parts in China, which speeds up the buying process and lowers the cost of materials. This integrated supply chain structure lets us provide lower prices while still meeting quality criteria for both prototype and production runs.

Key Criteria to Evaluate When Choosing an OEM/Custom PCB Assembly Factory

Creating a complete assessment framework makes sure that you choose the right partner for Custom PCB assembly and that your long-term relationship will be successful. The following characteristics are important for judging possible manufacturing partners.

Production Capabilities and Technological Sophistication

To address a wide range of project needs, modern PCB assembly needs advanced manufacturing skills. Check out possible partners depending on how well they can handle multilayer boards, from basic 2-layer designs to complicated 48-layer setups. Advanced facilities should be able to use blind and buried via technologies, manage impedance within a ±7% tolerance, and make high-density interconnect (HDI) products.

The most capable facilities offer comprehensive technology portfolios that include:

- Multi-layer PCB fabrication: Capability to produce boards with layer counts up to 48 layers, utilizing advanced lamination techniques and precise drilling processes for complex electronic designs requiring high component density and signal integrity.

- Surface finish options: Multiple surface finishing capabilities including HASL, ENIG, OSP, and immersion silver to meet different application requirements and ensure optimal component attachment and long-term reliability.

- Component placement precision: High-speed pick-and-place equipment capable of handling components from large connectors down to 01005 chip components with placement accuracies of ±0.02mm for demanding applications.

- Testing and inspection systems: Comprehensive quality control infrastructure including flying probe testers, in-circuit testing (ICT), and functional testing capabilities to ensure zero-defect delivery standards.

These technological capabilities directly impact product quality, manufacturing efficiency, and the ability to support complex design requirements across various industry applications.

Quality Assurance Systems and Certifications

Reliable PCB assembly processes are built on strong quality management systems. ISO 9001 for quality management, IATF 16949 for automotive applications, and IPC-A-610 for assembly requirements are just a few of the international certifications that top firms have. These certificates show that the company is dedicated to providing consistent quality and following the rules.

Quality control should entail checking incoming materials, keeping an eye on the process, and inspecting the end product. Advanced facilities use statistical process control (SPC) methods to keep failure rates at 0.2%, which is far lower than the industry average. X-ray inspection for BGA parts, automated optical inspection (AOI) for surface-mount assemblies, and functional testing techniques all help make sure that products are reliable.

Lead Time Management and Production Flexibility

Suppliers that can balance speed and quality are necessary for good project management. Check out possible partners based on how well they can provide you reliable lead time estimates, stick to production schedules, and meet urgent needs. The leading manufacturers provide accelerated services with 24/7 operations and continuous manufacturing capabilities. This cuts down on normal delivery times while still meeting quality requirements.

Comparing Top Custom PCB Assembly Solutions in China

There are many different types of PCB assembly companies in China, each with its own specialties, skills, and ways of doing business. Knowing these distinctions helps procurement managers make smart choices for Custom PCB assembly depending on the needs of each project.

Turnkey vs. Consigned Assembly Models

Turnkey assembly companies take care of all aspects of a project, from getting the parts to making the PCB to putting it all together and testing it. This method makes managing the supply chain easier, cuts down on procurement costs, and gives one person full responsibility. Turnkey providers usually have long-term connections with component distributors and provide bulk buying benefits that may lower the total cost of a project.

Consigned assembly operations only do assembly work, thus clients have to furnish all the parts and supplies. This strategy gives you more control over the parts and might save you money on large-scale manufacturing, but it makes the supply chain more complicated and needs more project management personnel.

Specialized vs. General Purpose Facilities

Manufacturers that specialize in one area, such automobile electronics, medical gadgets, or telecommunications equipment, are called "specialized manufacturers." These places usually have more knowledge about the rules and standards that apply to them, as well as specialized testing tools and certifications that are particular to their field. For example, those who put together medical devices must have ISO 13485 certification and work in cleanrooms that are necessary for healthcare settings.

General-purpose facilities may do many things and generally charge less for conventional applications. These manufacturers usually work with a wide range of sectors and are flexible enough to meet different project needs. This makes them a good fit for firms that make a lot of different products.

How to Efficiently Collaborate with Your Chosen Custom PCB Assembly Partner

To make sure a project is a success, partners need to work together in an organized way that improves communication, lowers risks, and makes sure the project is a success. Using good ways to work together from the start of a project to the delivery of the finished result builds long-lasting commercial partnerships.

Design for Manufacturing (DFM) Optimization

Full DFM evaluations throughout the design process are the first step toward good cooperation. Experienced assembly partners may provide you useful advise on how to choose parts, arrange them in the best way, and make them easier to make, all of which can lower manufacturing costs and make products more reliable. This team-based method finds possible problems before they happen, which cuts down on costly design changes and manufacturing delays.

DFM optimization looks at several things, such as checking the availability of components, making sure placement rules are followed, managing heat, and testing. Partners with good technical skills may offer other parts or design changes that make things easier to make without making them less useful.

Prototype Development and Testing Protocols

Structured prototyping techniques let you improve and test your idea several times before you start making a lot of copies. Good partners provide rapid prototyping services with fast turnaround times, which lets you make various design changes in a short amount of time. Comprehensive testing methods throughout the prototype phase find any problems and make sure that the design works as planned in real life.

Regular updates on progress, thorough test results, and ways for everyone to work together to solve problems as they come up should all be part of communication protocols. Real-time project monitoring technologies and video conferencing make it easier to work together from various time zones.

Ring PCB: Advanced Engineering for Precision PCB Manufacturing

Ring PCB is the leader in China's bespoke PCB assembly sector. They have decades of expertise in Custom PCB assembly and the latest production technology. Our integrated facility specializes in high-density stack-up configurations with 2 to 48 layers. It has blind and buried via technology and can handle traces and spaces as small as 3/3mil. With advanced impedance control within ±7% tolerance, our solutions are perfect for tough jobs in 5G communications, industrial control systems, medical devices, and automotive electronics.

Smart Manufacturing Infrastructure

Our own manufacturing plant has the most up-to-date production technology, such as LDI laser exposure systems, vacuum lamination equipment, and flying probe testing. With these modern methods, we can keep IPC-6012 Class 3 standards while making sure that the quality is always the same, no matter how much we make. Our smart manufacturing method uses automated production lines and expert technicians to keep an eye on things to make sure the best quality and efficiency.

Integrated PCBA Services and Turnkey Solutions

Ring PCB offers complete production solutions that include making PCBs, sourcing components, assembling SMTs, and testing their functionality. Our skilled engineering team provides a wide range of DFM and DFA optimization services that lower design risks and BOM costs. X-ray inspection, AOI testing, and 100% functional validation are all part of strict quality control procedures that make sure that delivery standards are met that go above and beyond what customers anticipate.

Vertical Integration and Supply Chain Control

Our vertical integration model gives us full control over getting raw materials, making things, and testing the end result. This all-encompassing method lets us keep up with high quality standards while still delivering affordable prices and dependable delivery times. Our triple quality assurance approach, which includes AOI, impedance testing, and thermal cycling, keeps failure rates at 0.2%, which is far better than what is normal in the industry.

We are committed to meeting worldwide quality standards and regulatory regulations, as shown by our global certifications like ISO 9001, IATF 16949, and RoHS compliance. Ring PCB is a trusted partner for complicated electronics production needs because of these certifications and our long history of working with OEM customers in North America and Europe.

Conclusion

To choose the best OEM/custom PCB assembly facility in China, you need to carefully look at their manufacturing capabilities, quality systems, and ways of working together. The best collaborations use innovative production technology together with customer service that is quick to respond and thorough quality assurance. Procurement managers may build solid supply chain connections that support long-term company development by working with certified manufacturers who have a history of success, clear pricing methods, and strong technical support capabilities. The objective is to find a balance between cost and quality while making sure that you have the right technical skills to suit the needs of current and future projects.

FAQs

Q1: What are typical lead times for Custom PCB assembly orders in China?

A: Depending on how complicated and how many you need, standard wait times are usually between 7 and 21 days. Prototype orders usually take 5 to 7 days to complete, while high-volume manufacturing might take 2 to 3 weeks. Expedited services may cut these times down a lot. Some manufacturers provide 24/7 operations and continuous manufacturing capabilities that get outcomes quicker than normal timetables.

Q2: How can I ensure quality when working with Chinese PCB assembly manufacturers?

A: To make sure the quality is good, you need to choose manufacturers who have well-known certifications like ISO 9001, IATF 16949, and IPC standards compliance. Before placing production orders, ask for specific quality control processes, inspection reports, and sample testing. The finest manufacturers keep failure rates below 0.2% by using thorough testing methods including AOI, X-ray inspection, and functional validation.

Q3: What minimum order quantities should I expect for custom PCB assembly?

A: The minimum order quantities (MOQs) are quite different depending on the manufacturer's skills and the project's difficulty. Most facilities can handle prototype volumes of 5 to 10 pieces, while production runs usually start at 100 to 500 units. Volume pricing benefits become important when you purchase more than 1,000 units. The best prices are for orders of more than 10,000 pieces.

Partner with Ring PCB for Superior Custom PCB Assembly Manufacturing

Ready to experience exceptional Custom PCB assembly services from a trusted manufacturer? Ring PCB delivers competitively priced solutions with expedited service featuring 24/7 online support and continuous 7-day production schedules, significantly outperforming standard delivery times for faster project completion. Our advanced capabilities include up to 48-layer multilayer circuit boards backed by international ISO certifications and comprehensive quality assurance systems. Contact us at [email protected] to discuss your project requirements and discover how our turnkey solutions can optimize your electronics manufacturing supply chain.

References

1. Zhang, L., & Wang, M. (2023). "Global PCB Manufacturing Trends and China's Market Position." Electronics Manufacturing Quarterly, 45(3), 78-92.

2. Chen, H., Liu, S., & Brown, R. (2022). "Quality Management Systems in Chinese PCB Assembly Operations." International Journal of Electronics Manufacturing, 31(8), 234-251.

3. Industry Research Institute. (2023). "PCB Assembly Market Analysis: Technology Trends and Regional Capabilities." Electronics Industry Report, 12(4), 156-178.

4. Thompson, J., & Li, W. (2023). "Supply Chain Integration in Asian Electronics Manufacturing." Manufacturing Technology Review, 28(7), 445-462.

5. Electronics Manufacturing Association. (2022). "Certification Standards and Quality Benchmarks for PCB Assembly Operations." Technical Standards Bulletin, 19(11), 23-41.

6. Rodriguez, C., Kim, S., & Zhao, F. (2023). "Advanced Manufacturing Technologies in PCB Production: A Comparative Analysis." Technology Innovation Journal, 41(2), 189-207.