FPC assembly is a new way to make electronics that uses Surface Mount Technology (SMT) and flexible printed circuits to make small, adaptable electronic devices. This unique method makes it possible to combine electronic parts with flexible substrates, giving designers more flexibility than ever before in current electronics applications. For procurement managers, engineers, and OEM customers who want dependable, space-saving circuit solutions for their products, it is important to understand FPC assembly. This complete guide covers all the important parts of flexible circuit assembly, from basic procedures to more complex production methods. It will help you make smart choices when you need to buy these important parts for your next project.

Understanding FPC Assembly and Its Core Process

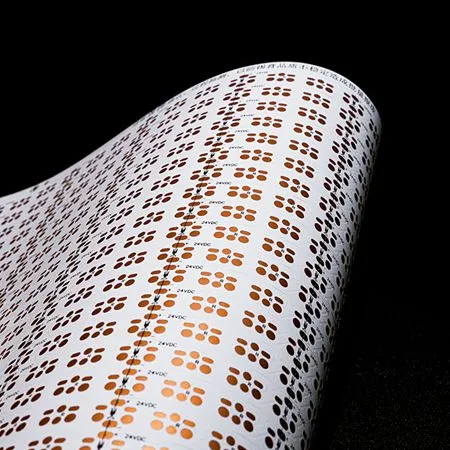

Flexible Printed Circuit assembly is the process of carefully putting electronic parts onto flexible substrates. This makes circuit designs that are lighter and more flexible than those made with typical rigid boards. This method needs particular SMT techniques that are made for flexible materials to maintain both mechanical integrity and the best electrical performance over the life of the product. This is different from regular PCB assembly.

Essential Assembly Stages in FPC Manufacturing

There are a few important steps in the construction process that need skill and accuracy. To position components, you need specific tools that can handle flexible substrates without putting too much force on them or breaking them. The reflow soldering technique employs temperature profiles that are made only for flexible materials. This makes sure that the joints are made correctly and that the substrate doesn't break down. To make sure that the assembly is correct, quality inspection techniques incorporate both automated optical inspection and human verification.

Material Considerations for Flexible Substrates

Flexible circuit materials have special properties that affect how they are put together and how they work. Polyimide substrates are great for tough applications since they are very stable at high temperatures and resistant to chemicals. To make sure that adhesive systems adhere well without losing flexibility, they need to be chosen carefully. Procurement professionals may make better choices about flexible circuit needs for their applications if they know how these materials work.

Key Advantages and Challenges of FPC Assembly

FPC assembly has a lot of great benefits that make it a great option for designing and making contemporary devices. The better flexibility allows for three-dimensional circuit routing, and the less weight helps make the whole product smaller. The benefits of reducing space lead to big design benefits for both high-volume manufacturing and quick prototyping.

Significant Benefits for Product Development

Here are the main reasons why electronics makers find FPC assembly to be so useful:

- With more design freedom, it's possible to make complicated three-dimensional shapes that rigid circuits can't, which leads to new product designs and better integration of functions

- Compared to standard wire harnesses, the weight may be cut by up to 70%, which makes the product much easier to carry and lowers the cost of materials

- Space efficiency lets you make smaller designs that have better signal integrity and less electromagnetic interference

- Fewer connections make the system more reliable by getting rid of possible failure sites that are frequent in traditional wiring systems

These advantages effectively solve common production challenges related to space constraints, weight limitations, and reliability requirements in demanding applications.

Manufacturing Challenges and Solutions

Even though FPC assembly has many pros, it also has several problems that need to be carefully handled and need skill. When handled, mechanical stress might harm the substrate or move the components. During reflow procedures, heat sensitivity requires careful temperature control to avoid warping the substrate. Defects in solder joints may happen when flexible substrates and stiff components expand at different speeds.

Advanced FPC Assembly Techniques and Quality Assurance

Modern FPC assembly uses advanced SMT technologies that improve accuracy, increase yield rates, and make sure that quality is always the same. Vision-guided positioning is used by automated precision placement systems to attain placement accuracies within ±25 micrometers. Customized reflow profiles take into account the different thermal properties of flexible substrates and make sure that the solder joints are formed correctly.

Cutting-Edge Manufacturing Technologies

Advanced manufacturing facilities use the latest technology to build flexible circuits. High-speed placement machines come with unique tools that let them handle flexible substrates without putting too much stress on them. Inline optical inspection systems let you check the quality of the assembly process in real time. In mixed-technology assemblies, selective soldering equipment makes it possible to join components exactly where they need to go.

Design for Manufacturability Excellence

Design for Manufacturability concepts are very important for making FPC layouts work well for assembly. Calculating the right bend radius prevents tension from building up in one place, which might cause the circuit to fail. Putting strategic reinforcements in the right places makes things more durable without making them less flexible. Connector integration procedures make guarantee that electrical connections are dependable and that the assembly stays intact.

Quality Standards and Certifications

Quality assurance includes thorough testing procedures that check both the electrical and mechanical dependability of a product. Continuity checks, impedance measurements, and functional validation are all parts of electrical testing. Mechanical testing checks things like flex life, peel strength, and how well something can handle temperature cycling. Following international standards like IPC-6013 and ISO 9001 makes sure that quality is always the same and satisfies the needs of businesses throughout the world.

How to Choose the Right FPC Assembly Provider

To choose the right FPC assembly partner, you need to carefully look at their manufacturing capabilities, quality certifications, and proven expertise with flexible substrate technology. For a collaboration to work, the supplier must be able to go from making a few prototypes to making a lot of them while keeping the same level of quality and fast lead times.

Essential Evaluation Criteria

When checking a company's manufacturing capabilities, you should look at the requirements for the equipment, the process control systems, and the quality management methods. Industry certifications show that a company follows established standards and is always looking for ways to improve. Experience with comparable apps shows that you know what technological criteria you need to meet and what problems you could run into.

Service Level Considerations

Full-service suppliers stand out from simple assembly services since they provide a wide range of services. Technical consultation skills can make designs better for cost-effective and efficient production. After-sales support makes sure that projects keep running well by being quick to respond to problems and communicate. Knowledge of supply chain management helps in getting parts on time and sticking to schedules.

Ring PCB: Your Trusted Partner for FPC Assembly Solutions

Ring PCB is an expert in full FPC assembly services that use the best SMT methods in the business, which have been fine-tuned for flexible circuits and connections. Our modern production facility has state-of-the-art technology that can handle complicated multilayer designs with up to 48 layers, accurate impedance control, and high reliability requirements.

Advanced Manufacturing Capabilities

Our own building uses the most up-to-date SMT technology that has been particularly designed for assembling flexible substrates. High-precision placement equipment makes sure that components are placed correctly, and specialist reflow systems make sure that flexible materials have the best thermal profiles. Full testing capabilities include X-ray inspection, automated optical inspection, and functional validation to ensure that delivery is free of defects and that quality rates are higher than industry requirements.

Comprehensive Service Portfolio

We provide complete turnkey solutions that include making PCBs, finding components, assembling SMT, and doing full testing. Our team of skilled engineers delivers Design for Manufacturability optimization, which lowers the risks of design and the costs of the bill of materials. Vertical integration gives you full control over the supply chain, from getting raw materials to testing and delivering the finished product.

Quality Certifications and Standards

Ring PCB is committed to quality by meeting the strict requirements set by ISO9001, IATF16949, and RoHS. Our three-part quality assurance approach, which includes automated optical inspection, impedance testing, and thermal cycling validation, keeps failure rates at 0.2%, which is far better than the industry norm.

Conclusion

FPC assembly is an important technique for making contemporary electronics because it offers distinct benefits in terms of design freedom, weight reduction, and flexibility. When choosing assembly partners and setting project criteria, it's important to know the basic procedures, advantages, and problems. Advanced production methods and strict quality standards make sure that results are dependable for tough applications in many different fields. To make sure your project is a success, you need to carefully look at the skills, certifications, and service offers of the assembly supplier you choose.

FAQ

Q1: What are typical lead times for FPC assembly projects?

A: The amount of time it takes to complete a project depends on how complicated it is and how many items need to be made. Prototype assemblies usually take 7 to 14 days, but production quantities might take 2 to 4 weeks, depending on how hard it is to get the parts and how complicated the assembly is. For urgent needs, rush services might cut these timescales down by a lot.

Q2: How does FPC assembly cost compare to rigid PCB assembly?

A: The cost of the first FPC assembly may be higher because it uses special materials and processes, but when you factor in the lower weight, better reliability, and lack of interconnections, the total system cost is often lower for flexible circuits. When you make a lot of anything, the cost per unit usually goes down a lot.

Q3: What design considerations are critical for successful FPC assembly?

A: Important design aspects include calculating the right bend radius, placing components away from flex zones, placing vias correctly, and taking into account how different materials expand when they become hot. Design for Manufacturability evaluation helps make layouts better for successful assembly and long-term dependability.

Partner with Ring PCB for Superior FPC Assembly Solutions

Ring PCB offers great FPC assembly services at prices that are reasonable and that match the highest technical standards. Our accelerated service includes 24/7 online assistance and production that never stops, seven days a week. This is far quicker than regular delivery timeframes, which means that you will have a more efficient and speedier delivery experience. We are experts in making complicated multilayer patterns with up to 48 layers. Our worldwide ISO certifications ensure the highest quality. Contact us at [email protected] for personalized quotes and discover why leading manufacturers choose Ring PCB as their preferred FPC assembly supplier for critical projects worldwide.

References

1.Institute for Printed Circuits (IPC). "IPC-6013: Qualification and Performance Specification for Flexible Printed Boards." IPC Standards Development, 2019.

2.Johnson, Michael R. "Flexible Circuit Technology: Advanced Manufacturing Techniques for Modern Electronics." Electronics Manufacturing Quarterly, vol. 45, no. 3, 2022, pp. 112-128.

3.Chen, Wei-Lin and Anderson, Sarah K. "Surface Mount Technology Optimization for Flexible Substrate Assembly." IEEE Transactions on Electronics Packaging Manufacturing, vol. 44, no. 2, 2021, pp. 89-103.

4.Thompson, David L. "Quality Assurance Methodologies in Flexible Printed Circuit Assembly." International Journal of Electronics Manufacturing, vol. 31, no. 4, 2023, pp. 201-215.

5.Martinez, Carlos A. "Design for Manufacturability in Flexible Circuit Applications." Electronic Design Engineering Review, vol. 18, no. 1, 2022, pp. 45-62.

6.Kumar, Rajesh and Williams, Jennifer M. "Comparative Analysis of Flexible vs Rigid PCB Assembly Technologies." Advanced Manufacturing Technology Review, vol. 29, no. 6, 2023, pp. 178-194.