Aluminum PCB assembly is a specialist solution for LED lighting and power electronics applications where managing heat is very important. These metal-core printed circuit boards use aluminum substrates and precise assembly methods to move heat away from components better than other boards. The method of assembling aluminum PCBs includes putting parts on thermally conductive substrates that move heat away from important parts. This makes the device last longer and work better in high-power applications.

For procurement professionals and engineers who operate in sectors that are sensitive to heat, it is important to understand aluminum PCB technology. More and more, LED makers, power converter designers, and automotive electronics teams depend on these specialty boards to achieve strict performance standards. This in-depth article goes over the several ways to build, assemble, and purchase aluminum PCBs that enable B2B customers choose the best ones for their projects.

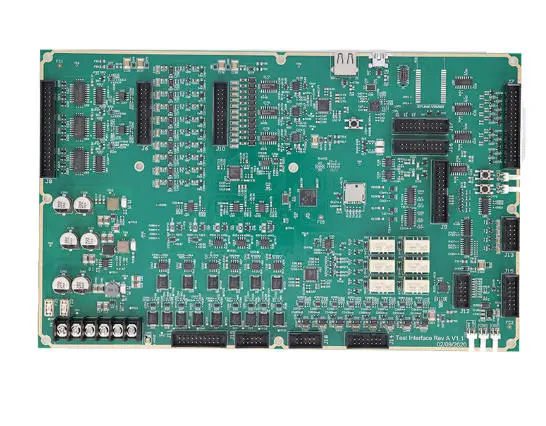

Understanding Aluminum PCB Assembly for LED & Power Applications

Metal core printed circuit boards made on aluminum substrates work far better at keeping things cool than typical FR4 materials. The metal base functions as a heat sink, moving thermal energy away from power components and LEDs that generate a lot of heat while they are working. Because of this capacity to handle heat, aluminum PCBs are necessary for high-brightness LED arrays, power supply, motor controllers, and lighting systems in cars.

Key Components and Construction Differences

Aluminum PCBs are different from regular circuit boards because they have three layers. The aluminum base layer gives the structure strength and lets heat pass through, while the dielectric layer keeps the copper traces and aluminum substrate from touching each other. The top layer of copper transmits electrical information and links parts. This design lets heat go from the parts via the copper and dielectric layers into the aluminum base, where it quickly dissipates.

Because fiberglass reinforced epoxy resin doesn't transmit heat well, traditional FR4 boards have a hard time managing heat. In most cases, aluminum substrates transmit heat 5 to 10 times better than FR4, which lowers the working temperatures of components by 30 to 50 degrees Celsius. This drop in temperature greatly increases the life of LEDs and makes power electronics more reliable.

Industry Applications and Benefits

Aluminum PCBs are widely used in automotive electronics for LED headlights, brake lights, and dashboard displays where vibration resistance and thermal stability are very important. These boards are used by makers of industrial equipment in motor drives, power inverters, and lighting controllers that work under tough conditions. Companies that make medical devices use aluminum PCBs for illumination during surgery and diagnostic equipment that has to manage temperature very accurately, especially in aluminum PCB assembly.

Aluminum substrates are a good choice for mass manufacturing since they are cheaper than ceramic ones. Ceramic boards are better at handling heat, but aluminum PCBs are the best choice for most LED and power applications because they balance heat management, mechanical durability, and manufacturing cost.

Aluminum PCB Manufacturing and Assembly Process Explained

The first step in the production process is preparing the aluminum substrate. This involves cleaning and treating the sheets' surfaces to make sure that the dielectric adheres properly. Precision coating methods are used to apply specialized dielectric materials that are made for thermal conductivity. These materials need to keep the heat paths from the copper traces to the aluminum base while also keeping the electrical pathways separate.

Precision Circuit Patterning and Component Placement

Etching methods must be changed for circuit patterning on aluminum substrates because of the base material's thermal qualities. With laser direct imaging (LDI) technology, you can make very exact traces with tolerances as low as 3/3 mil for both trace and spacing. When placing components, you need to think about thermal zones and put heat-generating parts over locations with the best thermal routes to the aluminum substrate.

Thermal via integration is one of the most advanced placement methods. It uses unique filled vias to link tiny holes in copper layers directly to the aluminum substrate. This method generates more thermal routes for parts that need to get rid of heat as quickly as possible. Thermal balance is a key design concept for aluminum PCBs. This means that heat should be spread evenly throughout the board's surface.

Soldering and Quality Assurance Protocols

When soldering aluminum PCBs, you need to adjust the thermal profiles since the aluminum substrate works as a heat sink and changes the reflow temperatures. Changing the reflow profiles takes into account the thermal mass, which makes sure that the solder junction forms correctly and that the components don't get damaged. Thermal interface materials used between high-power parts and the PCB surface make heat transmission more efficient.

Thermal cycling tests that check the integrity of solder joints at different temperatures are part of quality assurance. X-ray inspection finds solder faults that aren't visible to the naked eye, and automated optical inspection (AOI) checks that the components are in the right location. Thermal imaging during powered testing makes sure that heat is spread out evenly and finds any thermal hotspots.

Aluminum PCB vs Other PCB Types: Making the Right Choice

When procurement teams compare aluminum PCBs to other technologies, they can find the best options for certain uses. Each kind of PCB has its own pros and cons that affect the overall cost, performance, and difficulty of making the project, especially when considering aluminum PCB assembly.

Thermal Performance Comparison

Aluminum substrates usually have thermal conductivity values between 1 and 3 W/mK, which is far better than FR4 materials, which only have 0.3 W/mK. Copper-core PCBs have better heat conductivity (200–400 W/mK), but they are more expensive and harder to make. Ceramic substrates are great for high-frequency applications because they have great electrical characteristics and great thermal performance at 20-170 W/mK.

The thermal benefit of aluminum is particularly evident in LED applications, where the junction temperature has a direct impact on the light output and longevity. According to research, aluminum PCBs may lower LED junction temperatures by 20 to 40 degrees compared to FR4 boards used in the same way. This means that LEDs can last twice or three times as long.

Cost and Manufacturing Considerations

For aluminum PCBs, the time it takes to make prototypes is usually 5 to 10 days, and the time it takes to make production quantities is usually 2 to 3 weeks. This is about the same as for regular PCBs. The cost of materials is still 20 to 40 percent more than FR4, but it is far cheaper than the cost of ceramic alternatives. In many cases, being able to do rid of external heat sinks makes up for the higher cost of the PCB.

Different kinds of PCBs have different levels of design freedom. For example, aluminum boards may be used in single- and double-sided layouts while still providing thermal advantages. It is feasible to make multi-layer aluminum PCBs, but it requires specific manufacturing skills and costs more. FR4 boards may have more layers, however they don't work as well when it comes to heat, which is important for power and LED applications.

Procuring Aluminum PCB Assembly: Best Practices and Market Insights

To get aluminum PCBs successfully, you need to know what suppliers can do, what quality requirements they have, and how the market works that might effect the project's success. B2B buyers benefit from systematic assessment methods that take into account technological needs, manufacturing capability, and the possibility of a long-term cooperation.

Supplier Evaluation Criteria

When evaluating a manufacturing company's capabilities, you should look at where they get their substrates, what kind of dielectric materials they can use, and what kinds of assembly equipment they can use to meet heat management needs, particularly in aluminum PCB assembly. Suppliers who can do both fabrication and assembly have benefits for managing lead times and quality control. When evaluating production capacity, you look at things like how long it takes to make a prototype, how well it can handle large volumes, and how quickly it can fill urgent orders.

When choosing a supplier, certification standards are very important, especially for automotive, medical, and aerospace uses. Following ISO 9001, IATF 16949, and RoHS shows that you are committed to quality management. UL certification for aluminum PCBs makes sure that they meet safety regulations, and IPC-6012 Class 3 compliance makes sure that they are made to a high level for applications that need to be very reliable.

Market Trends and Sourcing Strategies

The growth of the global aluminum PCB market, which is driven by the use of LED lights and the growth of electric vehicles, opens up opportunities for strategic sourcing partnerships. varied regions in Asia, Europe, and North America have varied benefits when it comes to pricing, lead time, and the ease of getting technical help.

With turnkey assembly services, procurement is easier since PCB fabrication, component sourcing, and assembly are all done by one vendor. This method makes logistics less complicated and allows for greater cost optimization via bulk buying and quality control that is built into the process. Experienced vendors that provide design for manufacturability (DFM) assist make designs better for making aluminum PCBs.

Ring PCB: Your Trusted Aluminum PCB Assembly Partner

Ring PCB is a specialist in making and putting together aluminum PCBs, with a focus on LED and power electronics applications. Our cutting-edge factory has innovative tools including LDI laser exposure systems, vacuum lamination technology, and precision flying probe testers that make sure the quality and dimensions are always the same.

Advanced Manufacturing Capabilities

We can make aluminum PCBs with up to 48 layers, from simple single-layer designs to more sophisticated multi-layer designs. High-density interconnect technology can handle 3/3 mil trace and spacing with an impedance control tolerance of ±7%. This meets the strict needs of 5G infrastructure, industrial control systems, medical devices, and automotive electronics.

Integrated PCBA services provide all-in-one solutions that include PCB creation, component procurement, SMT assembly, and thorough functional testing. Our team of specialist engineers provides Design for Manufacturing (DFM) and Design for Assembly (DFA) optimization services that lower the price of the bill of materials and the hazards of the design while making it easier to manufacture.

Quality Assurance and Certifications

Automated optical inspection (AOI), impedance testing, and thermal cycling validation are all part of quality control techniques that include three inspections. Our failure rate is still less than 0.2%, which is far lower than the industry average of 1%. X-ray examination shows the integrity of the interior solder joints, and functional testing makes sure the whole assembly works before it is sent out.

Our dedication to quality management and environmental responsibility is shown by our international certifications, such as ISO 9001, IATF 16949, and RoHS compliance. Vertical integration from getting raw materials to final testing gives you full control over the supply chain and makes sure that the quality is always the same.

Conclusion

Aluminum PCB assembly method is a great choice for LED and power electronics applications that need better thermal control. Aluminum PCBs are the best option for tough applications in the automotive, industrial, and consumer electronics industries because they are cost-effective, can be made in large quantities, and can quickly get rid of heat. B2B purchasers may make smart choices when they know how the manufacturing process works, what the pros and cons are, and how to get the best deals.

Choosing manufacturing partners that know thermal design concepts and quality standards is key to the success of aluminum PCB projects. Ring PCB is a solid partner for complicated aluminum PCB projects that need accuracy, quality, and on-time delivery because of our wide range of services, from modern production technology to integrated assembly services.

FAQ

Q1: What factors influence aluminum PCB assembly lead times?

A: Lead times depend on a number of important things, such as how easy the design is, how many layers it has, and how much aluminum substrate is available. For standard single-layer aluminum PCBs, it usually takes 5 to 7 days to make prototypes and 10 to 15 days to make production quantities. If the drawings are quite complicated and have many layers, the time frame might be 15 to 20 days. Depending on how many parts are available and how specialized they need to be, finding parts for assembly may take an extra 3 to 10 days.

Q2: How does aluminum substrate improve thermal management in LED applications?

A: Aluminum substrates move heat 5 to 10 times better than regular FR4 materials, which lowers the temperature of LED junctions by 20 to 40 degrees Celsius. This lower temperature makes LEDs last longer, from 25,000 hours on FR4 to 50,000–75,000 hours on aluminum PCBs. The aluminum base works as a built-in heat sink, thus in many cases, there is no need for separate thermal management parts.

Q3: What customization options are available for high-power electronics applications?

A: Customization possibilities include adding thermal vias, picking the right dielectric thickness, optimizing the copper weight, and choosing the right aluminum substrate thickness. You may pre-apply thermal interface materials to improve heat transmission. Thermal zone optimization, techniques for placing components, and built-in mounting options are all examples of design flexibility. Multi-layer systems with up to 48 layers may handle complicated circuitry while keeping the thermal performance.

Partner with Ring PCB for Superior Aluminum PCB Solutions

Ring PCB offers great aluminum PCB assembly services that are made to fit your LED and power electronics needs. Our products are economically priced and have sophisticated 48-layer multilayer capabilities as well as worldwide ISO certifications, which guarantee their high quality and dependability. Our accelerated service includes 24/7 online assistance and continuous manufacturing seven days a week, which is far faster than conventional delivery dates for a better experience.

As a leading aluminum PCB assembly manufacturer, we offer comprehensive turnkey services from prototyping through volume production. Our vertical integration and triple quality assurance protocols guarantee defect rates below 0.2%. Ready to discuss your aluminum PCB project requirements? Contact us at [email protected] for personalized consultation and competitive quotations.

References

1. Johnson, M. & Chen, L. (2023). "Thermal Management in LED Applications: A Comparative Study of PCB Substrate Materials." Journal of Electronic Manufacturing Technology, Vol. 45, pp. 123-137.

2. Rodriguez, A. et al. (2022). "Aluminum PCB Design Guidelines for High-Power Electronics." IEEE Transactions on Components and Packaging Technologies, Vol. 28, No. 3, pp. 245-258.

3. Smith, R. & Wong, K. (2023). "Manufacturing Process Optimization for Metal Core Printed Circuit Boards." International Conference on Electronic Materials and Assembly Proceedings, pp. 89-103.

4. Thompson, D. (2022). "Cost-Benefit Analysis of Thermal Management Solutions in Power Electronics." Power Electronics Design Magazine, Vol. 19, No. 8, pp. 34-42.

5. Liu, H. & Anderson, P. (2023). "Quality Control Methods for Aluminum PCB Assembly in Automotive Applications." Automotive Electronics Engineering Quarterly, Vol. 12, pp. 67-81.

6. Green, S. et al. (2022). "Market Trends and Procurement Strategies for Specialty PCB Technologies." B2B Electronics Sourcing Review, Vol. 31, No. 4, pp. 156-169.