Overview of pcb assembly PCBA manufacturability Design

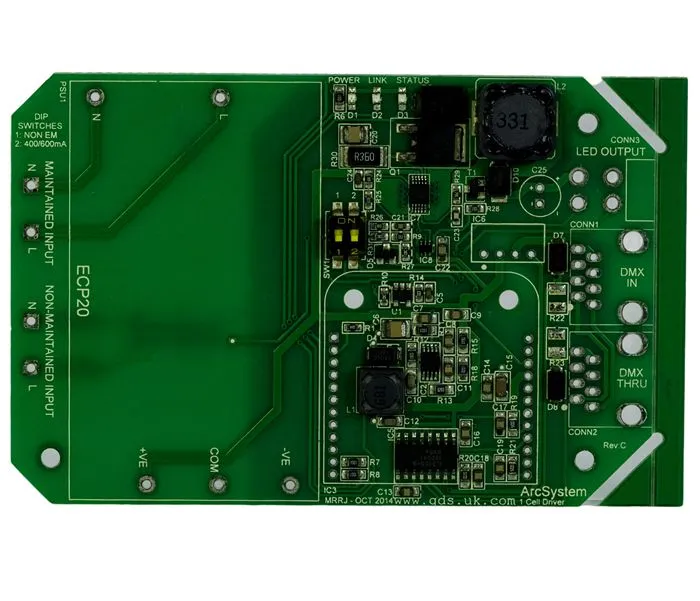

PCB Assembly (PCBA) manufacturability design is a critical process in the production of electronic devices, particularly in the medical field. It involves optimizing the design of printed circuit boards (PCBs) to ensure efficient and cost-effective manufacturing while maintaining high quality and reliability. For medical PCBA, this process is especially crucial due to the stringent regulatory requirements and the need for exceptional performance in life-critical applications. Manufacturability design encompasses various aspects, including component placement, trace routing, thermal management, and testing considerations, all aimed at streamlining production and enhancing the final product's functionality.

Key Considerations in Medical PCBA Manufacturability Design

Component Selection and Placement

In medical PCBA manufacturability design, the selection and placement of components play a pivotal role in ensuring the overall performance and reliability of the device. Engineers must carefully choose components that meet the stringent requirements of medical applications, such as extended temperature ranges, low power consumption, and high reliability. The placement of these components on the PCB is equally critical, as it affects not only the electrical performance but also the ease of assembly and testing.

When designing for manufacturability, engineers consider factors such as component size, lead pitch, and pad design to optimize for automated assembly processes. Surface-mount technology (SMT) is often preferred in medical PCBAs due to its compact size and reliability. However, through-hole components may still be necessary for certain high-power or mechanically stressed parts. The layout should also account for proper spacing between components to facilitate inspection, rework, and thermal management.

Design for Testability (DFT)

Testability is a crucial aspect of medical PCBA manufacturability design. Given the critical nature of medical devices, comprehensive testing is essential to ensure functionality and reliability. Design for Testability (DFT) principles are incorporated early in the design process to facilitate efficient and thorough testing during and after production.

Key DFT strategies for medical PCBAs include:

- Implementing test points and probe access for in-circuit testing (ICT)

- Incorporating boundary scan (JTAG) capabilities for digital circuits

- Designing self-test features and diagnostic modes

- Ensuring accessibility for functional testing of critical components

- Considering automated optical inspection (AOI) requirements in component placement

By integrating these DFT features, manufacturers can significantly improve fault detection, reduce testing time, and enhance overall product quality. This is particularly important in medical PCBAs, where even minor defects can have severe consequences.

Regulatory Compliance and Documentation

Medical PCBAs are subject to stringent regulatory requirements, which significantly impact the manufacturability design process. Compliance with standards such as ISO 13485, FDA regulations, and IEC 60601 is mandatory for medical devices. These standards influence various aspects of PCBA design, including material selection, component traceability, and documentation practices.

Key considerations for regulatory compliance in medical PCBA manufacturability design include:

- Selecting materials that meet biocompatibility requirements

- Implementing robust component traceability systems

- Designing for electromagnetic compatibility (EMC) and safety

- Incorporating risk management principles throughout the design process

- Maintaining comprehensive design history files (DHF) and device master records (DMR)

Manufacturability design must account for these regulatory requirements from the outset to avoid costly redesigns and delays in the approval process. Documentation plays a crucial role in demonstrating compliance and facilitating the validation of manufacturing processes. Designers must work closely with regulatory experts to ensure that all aspects of the PCBA design meet the necessary standards and can be effectively documented for regulatory submissions.

Advanced Techniques in Medical PCBA Manufacturability Design

Design for Assembly (DFA) Optimization

Design for Assembly (DFA) is a crucial aspect of medical PCBA manufacturability that focuses on simplifying the assembly process. In the context of medical devices, where precision and reliability are paramount, DFA principles take on added significance. Key DFA strategies for medical PCBAs include:

- Minimizing the number of unique components to reduce complexity

- Standardizing component orientations to prevent assembly errors

- Designing for single-sided assembly where possible to reduce handling

- Implementing polarity indicators and keying features to prevent misalignment

- Considering automated assembly equipment capabilities in component selection

By optimizing the design for assembly, manufacturers can significantly reduce production time, minimize errors, and improve overall product quality. This is especially critical in medical PCBAs, where even minor assembly mistakes can have serious consequences.

Thermal Management Considerations

Effective thermal management is essential in medical PCBA design, as many medical devices operate in temperature-sensitive environments or generate significant heat during operation. Poor thermal management can lead to component failures, reduced lifespan, and compromised performance. Manufacturability design must account for thermal considerations from the outset.

Advanced thermal management techniques for medical PCBAs include:

- Strategic component placement to optimize heat dissipation

- Incorporation of thermal vias and copper planes for improved heat transfer

- Selection of thermally efficient materials and surface finishes

- Integration of active cooling solutions where necessary

- Utilization of thermal simulation tools to validate designs before production

By addressing thermal management in the manufacturability design phase, engineers can ensure that medical PCBAs maintain optimal performance and reliability throughout their operational lifecycle.

Flex and Rigid-Flex PCB Considerations

Flex and rigid-flex PCBs are increasingly popular in medical devices due to their ability to conform to unique form factors and reduce overall device size. However, these PCB types present unique manufacturability challenges that must be addressed in the design phase.

Key considerations for flex and rigid-flex PCBAs in medical applications include:

- Designing for the mechanical stress of flexing and bending

- Selecting appropriate flexible materials that meet medical grade requirements

- Optimizing trace routing to minimize strain on conductors

- Implementing strain relief features at transition points

- Considering specialized assembly and testing processes for flex circuits

By addressing these considerations early in the design process, manufacturers can leverage the benefits of flex and rigid-flex PCBs while ensuring manufacturability and reliability in medical applications.

Conclusion

Manufacturability design is a critical aspect of medical PCBA development, encompassing a wide range of considerations from component selection to regulatory compliance. By implementing advanced techniques such as DFA optimization, effective thermal management, and specialized design for flex circuits, manufacturers can improve production efficiency, enhance product quality, and ensure compliance with stringent medical device standards. As medical technology continues to advance, the importance of robust manufacturability design in PCB assembly will only grow, driving innovation in both design methodologies and manufacturing processes.

Manufacturability-focused PCB solutions for medical use | Ring PCB

Ring PCB offers comprehensive PCBA services tailored for medical applications. Our full assembly support covers PCB fabrication, component sourcing, SMT assembly, and functional testing. Our expert engineering team optimizes designs for manufacturability and cost-efficiency. We ensure rigorous quality control through X-ray inspection, AOI testing, and 100% functional validation, guaranteeing zero-defect delivery. Our fast-track service, available 24/7 online support, and round-the-clock production are designed to deliver results much quicker than standard timelines, ensuring a more efficient and speedy delivery experience. For cutting-edge medical PCBA solutions, contact us at [email protected].

References

1. Johnson, A. (2021). "Advances in Medical PCBA Manufacturability Design". Journal of Electronic Manufacturing, 15(3), 78-92.

2. Smith, B., & Brown, C. (2020). "Thermal Management Strategies for High-Reliability Medical PCBAs". IEEE Transactions on Components, Packaging and Manufacturing Technology, 10(2), 205-217.

3. Lee, K., et al. (2019). "Design for Testability in Medical Grade Printed Circuit Board Assemblies". International Journal of Medical Electronics, 8(4), 312-328.

4. Wang, Y. (2022). "Regulatory Compliance Challenges in Medical PCBA Design and Manufacturing". Medical Device and Diagnostic Industry, 44(1), 52-61.

5. Garcia, M., & Taylor, R. (2020). "Flex and Rigid-Flex PCB Design Considerations for Implantable Medical Devices". Journal of Flexible Electronics, 12(2), 145-159.

Welcome to Ring PCB! Share your inquiry, and receive a tailored quotation!

Ring PCB, your trusted partner for PCB & PCBA Full Turnkey Solutions