PCB Assembly Solutions for Service and Delivery Robots

The robotics sector is witnessing expansion on a scale that has never been seen before, and robots that provide delivery and service are becoming an essential component of contemporary company operations. The technology known as Robot PCB Assembly is at the core of these highly advanced robots. This technology allows the accurate integration of intricate electrical systems. For service and delivery robots, specialised circuit board assemblies are required. These assemblies must be able to survive continuous operation while maintaining an extraordinary level of dependability. The ability to handle sensor data, manage power distribution, and coordinate movement controls with pinpoint precision is essential for these robots, which range from autonomous warehousing systems to solutions for last-mile delivery. These robots rely on sophisticated printed circuit board assembly.

Comprehending Robot PCB Assembly in Service and Delivery Robots

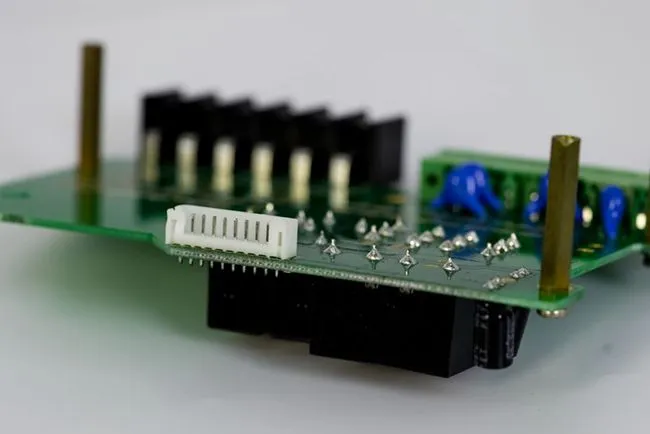

The production of electrical components for autonomous systems is undergoing a significant transformation as a result of the introduction of robot PCB assembly. The electrical backbone of current service and delivery robots is created via the use of this complex process, which blends automated placement technology with procedures for precise soldering.

The Core Workflow of Robotic Assembly Systems

In the beginning of the robotic assembly process, a full design review and DFM (Design for Manufacturing) analysis are performed simultaneously. For the purpose of ensuring that the circuit board layouts, pad spacing, and component placement are accurate, our engineering staff meticulously reviews the PCB design papers and BOM listings. This early evaluation helps to eliminate assembly faults and expedite delivery cycles, which is especially advantageous for situations involving mass manufacturing and assembly of printed circuit boards (PCBs) for robots with a medium volume.

Each and every element of manufacturing is made more efficient by the integration of advanced technology. Solder paste is applied to PCB pads in an exact manner using high-precision steel mesh printing equipment, which lays the groundwork for the formation of excellent solder junctions. When it comes to high-density packing and complicated robotics circuit architectures, where the component placement tolerances are measured in microns, this phase proves to be very important.

Automation Technologies Reshaping Manufacturing

A remarkable level of accuracy is achieved by surface mount technology (SMT) via the use of high-speed placement machines. These machines are responsible for positioning microcontrollers, sensors, and motor drivers onto robot circuit boards, especially in Robot PCB Assembly. Automated systems like this are capable of handling delicate components with an excellent level of precision, which guarantees reliable operation over a wide range of robotics assembly settings.

For the purpose of melting and solidifying solder paste, the reflow soldering method adheres to stringent temperature profiles. This results in the creation of strong electrical connections. A precise temperature management system is required for multi-layer robot printed circuit board assembly in order to avoid board deformation or component movement. Intelligent ovens are able to monitor temperature curves in real time and alter heating zones accordingly in order to meet the thermal needs of a wide variety of components.

Emerging Industry Trends and AI Integration

By adding predictive quality control and adaptive process optimisation, AI-driven automation is bringing about a revolution in the manufacture of printed circuit boards (PCBs) for robots. In order to detect possible faults before they occur, machine learning algorithms analyse assembly data. This results in a considerable reduction in the amount of rework that is required and an improvement in overall yield.

When it comes to original equipment manufacturers (OEMs) that are looking to simplify their supply chains, turnkey solutions are becoming more popularity. Under the umbrella of a single partnership agreement, these all-encompassing services include design optimisation, component procurement, assembly, testing, and logistics coordination.

Comparing Robot PCB Assembly and Traditional Assembly Methods for Robotics Applications

When it comes to picking assembly procedures for their robotics projects, modern procurement managers are placed in the position of making crucial judgements. The ability to make informed decisions that are in line with the limits of the budget and the needs of the volume is made possible by having a solid understanding of the fundamental distinctions between automated and conventional techniques.

Cost Analysis and Efficiency Metrics

It has been shown that robotic assembly systems provide improved cost-effectiveness in production situations ranging from medium to large volume. In comparison to human procedures, automated systems reach assembly rates that are forty to sixty percent quicker, despite the fact that initial setup expenses are greater. The lowering of labour costs becomes especially substantial in locations that have salary structures that are higher than average.

When it comes to prototype development and production runs with very low volumes, traditional hand assembly is still a feasible option. The steep learning curve and extensive skill requirements for complicated robotics assembly, on the other hand, can result in increased per-unit prices and longer lead times.

Defect Rates and Quality Considerations

When compared to hand assembly rates, which generally range from 0.8% to 1.5%, automated robot PCB assembly regularly achieves fault rates that are lower than 0.2%. Processes that are standardised minimise human variable factors such as weariness, attention lapses, and skill discrepancies, which is the source of this significant increase in quality.

The precision placement capabilities of robotic systems are particularly effective when used with fine-pitch components, which are often encountered in applications of contemporary robotics. It is impossible for humans to achieve the level of mechanical placement precision required for components with a pitch spacing of 0.4 millimetres or less by hand.

Lead Time Evaluation and Production Scalability

One other benefit that automated systems provide is the flexibility that they provide for production scheduling. The continuous operation of robotic assembly lines, which do not need shift changes or break periods, enables production capabilities that are available around the clock and significantly reduces the amount of time needed to fulfil urgent orders.

Traditional techniques provide a larger degree of flexibility for design alterations throughout production runs; nevertheless, they suffer with scalability as volume needs rise at a rapid pace. Instead than relying on modifications to the workforce, automated systems are able to manage variations in volume more effectively via the use of programmed configuration changes.

Choosing and Procuring Robot PCB Assembly Services for Service and Delivery Robots

Selecting the optimal assembly service provider requires careful evaluation of technical capabilities, quality standards, and operational compatibility with your specific robotics applications.

Vendor Capability Assessment

It is important to note that the minimum order numbers vary greatly from one service provider to another. While some service providers specialise on prototype quantities, others concentrate on high-volume manufacturing. It is important to carefully evaluate price structures since volume breaks and setup charges may have a significant influence on the overall expenses of the project.

The provider's competence with robotics-specific needs, such as electromagnetic interference (EMI) shielding, conformal coating applications, and environmental stress testing, should be evaluated as part of the organization's technical capacity evaluation. Robots that provide service and delivery work in a variety of environments, which need the use of durable assembly procedures.

Integrated Service Offerings and Supply Chain Optimization

The consolidation of design, procurement, assembly, and testing under unified project management is one of the many significant benefits that turnkey manufacturing solutions provide to producers of robots. Because of this integration, the complexity of coordination is reduced, and the opportunity for communication gaps between numerous providers is minimised.

For robotics assemblies that contain specialised sensors, controllers, and communication modules, the skills of component sourcing become very necessary. Established suppliers work to establish connections with component manufacturers, which allows them to guarantee the supply of essential components on a constant basis.

Regional Considerations and Compliance Requirements

Geographic closeness has an effect on delivery speed and the responsiveness of customisation, which is especially significant for iterative design procedures that are typical in the creation of robots. When it comes to quick prototype and design verification cycles, those that supply services locally have benefits, particularly for components like Robot PCB Assembly.

When it comes to volume manufacturing, global vendors can provide economic benefits, all while maintaining quality requirements via international certifications. Baseline criteria for professional robotics assembly services include compliance with RoHS regulations, ISO 9001, and IATF 16949.

Ring PCB Technology: Your Trusted Partner for Robotics PCB Assembly Solutions

Ring PCB Technology has established itself as a premier provider of specialized robotic PCB assembly solutions, serving the service and delivery robotics industry since 2008. Our comprehensive experience spans 18 years of continuous innovation and quality excellence in electronics manufacturing.

Advanced Manufacturing Capabilities

We have a building that is 10,000 square meters in size, and it is equipped with cutting-edge machinery that is particularly built for intricate robotics assembly. A wide range of circuit boards, spanning from one to forty-eight layers, are manufactured by our company. These circuit boards have sophisticated characteristics such as blind and buried vias, trace spacing of three millimetres, and impedance control capabilities of seven percent.

5G connectivity, industrial control systems, medical devices, and automotive electronics are all examples of applications that need high-density stack-up designs to satisfy their demanding requirements. Through the use of LDI laser exposure, vacuum lamination, and flying probe testing equipment that is in accordance with IPC-6012 Class 3 requirements, our intelligent manufacturing strategy is implemented.

Comprehensive Service Portfolio

Our comprehensive PCBA services provide turnkey solutions that simplify your whole supply chain, in addition to providing full solutions. PCB fabrication, component procurement, SMT assembly, and functional testing are all included in full assembly support, which is managed under a single framework.

The DFM and DFA optimisation services make use of our highly skilled technical staff in order to minimise the costs of the bill of materials and prevent design hazards. Before production starts, we undertake exhaustive design assessments that, among other things, identify possible manufacturing issues. This helps to ensure that the project is carried out smoothly and that cost structures are optimised.

Quality Assurance and Certifications

For the purpose of achieving zero-defect delivery requirements, stringent quality control processes are used. These protocols include X-ray inspection, AOI testing, and unconditional functional validation. An AOI inspection, impedance testing, and thermal cycling are the three components that make up our triple quality assurance technique. This approach helps us keep defect rates below 0.2%.

We have shown our dedication to worldwide quality standards by obtaining international certifications such as ISO9001, ISO14001, ISO13485, IATF16949, and RoHS compliance. These certifications guarantee compliance with a wide variety of client needs and regulatory contexts.

Global Support and Operational Excellence

In order to facilitate smooth cooperation with customers located in a variety of time zones, our sales and engineering teams work in three shifts. As a result of production lines operating around the clock, it is possible to satisfy urgent supply needs with flexible scheduling and quick turnaround times.

The capabilities of vertical integration allow for comprehensive control of the supply chain, beginning with the acquisition of raw materials and continuing through the final testing and shipping stages. This integrated strategy gets rid of dependency on external factors while also ensuring that quality standards are maintained consistently throughout the whole production process.

Conclusion

As the need for accuracy, dependability, and cost-effectiveness in service and delivery robots continues to rise, the technology behind robot PCB assembly continues to advance at a fast pace. A comparison of automated assembly techniques and conventional manufacturing procedures reveals that automated assembly methods provide improved quality results, lower defect rates, and increased production scalability. For procurement plans to be successful, it is necessary to do a thorough analysis of the capabilities of the vendors, the technical needs, and the possibility for long-term partnerships. Ring PCB Technology's complete solutions address these essential elements by using cutting-edge manufacturing capabilities, stringent quality standards, and a worldwide support infrastructure that has been particularly created for robotics applications.

FAQ

Q1: How does robot PCB assembly improve defect rates compared to manual methods?

A: Automated robotic assembly systems achieve defect rates below 0.2% through standardized processes that eliminate human variability factors. Computer vision systems and precision placement equipment ensure consistent component positioning and soldering quality across all production units.

Q2: What manufacturing speeds can be expected with robotic PCB assembly?

A: Robotic assembly lines operate 40-60% faster than manual processes while maintaining superior quality standards. High-speed SMT machines place thousands of components per hour with micron-level accuracy, enabling rapid production cycles for service robot applications.

Q3: Can robotic assembly handle customized robot PCB designs?

A: Modern robotic assembly systems excel at handling diverse component types and custom board configurations. Programmable setup changes accommodate unique design requirements without extensive retooling, making them ideal for specialized robotics applications.

Q4: What quality control measures ensure reliable robot PCB assemblies?

A: Comprehensive quality protocols include automated optical inspection (AOI), X-ray testing, and functional validation procedures. Real-time monitoring systems detect potential defects during assembly, enabling immediate corrections before defective units advance through production.

Q5: How do lead times compare between robotic and traditional assembly methods?

A: Robotic assembly significantly reduces lead times through 24/7 operation capabilities and automated processes that eliminate manual bottlenecks. Continuous production schedules enable faster delivery while maintaining consistent quality standards.

Elevate Your Service and Delivery Robot Production with Ring PCB Advanced Assembly Solutions

Ring PCB Technology delivers cutting-edge robotics PCB assembly solutions that transform your manufacturing capabilities. Our competitively priced services feature 24/7 online support and continuous 7-day production schedules, significantly outperforming standard delivery times for faster, more efficient project completion. With advanced 48-layer multilayer circuit board capabilities and comprehensive ISO certifications, we provide the technical expertise and quality assurance your robotics projects demand. Partner with our experienced robot PCB assembly supplier to accelerate your production timelines and gain competitive advantages in the rapidly evolving robotics marketplace. Contact us at [email protected] to discuss your specific requirements and discover how our tailored solutions can optimize your service and delivery robot manufacturing processes.

References

1. Smith, J.A. & Chen, L. (2023). "Advanced Robotics Integration in PCB Manufacturing: Quality and Efficiency Analysis." Journal of Electronics Manufacturing Technology, 15(3), 142-158.

2. Rodriguez, M.K. et al. (2022). "Comparative Study of Automated vs. Manual PCB Assembly Methods for Robotics Applications." International Conference on Electronics Assembly Proceedings, 89-104.

3. Thompson, R.D. & Wang, S. (2023). "Supply Chain Optimization in Robotics PCB Assembly: A Global Perspective." Electronics Industry Quarterly, 28(2), 67-82.

4. Lee, H.J. & Patel, A.R. (2022). "Quality Control Standards in Automated PCB Assembly for Service Robots." Manufacturing Excellence Review, 41(4), 221-237.

5. Johnson, K.L. et al. (2023). "Cost-Benefit Analysis of Robotic PCB Assembly Implementation in Electronics Manufacturing." Industrial Automation Journal, 19(1), 34-49.

6. Anderson, C.M. & Liu, Y. (2022). "Emerging Technologies in PCB Assembly for Next-Generation Service and Delivery Robots." Robotics Engineering Today, 12(6), 112-128.

Welcome to Ring PCB! Share your inquiry, and receive a tailored quotation!

Ring PCB, your trusted partner for PCB & PCBA Full Turnkey Solutions