PCBA Challenges in Autonomous Robot Control Systems

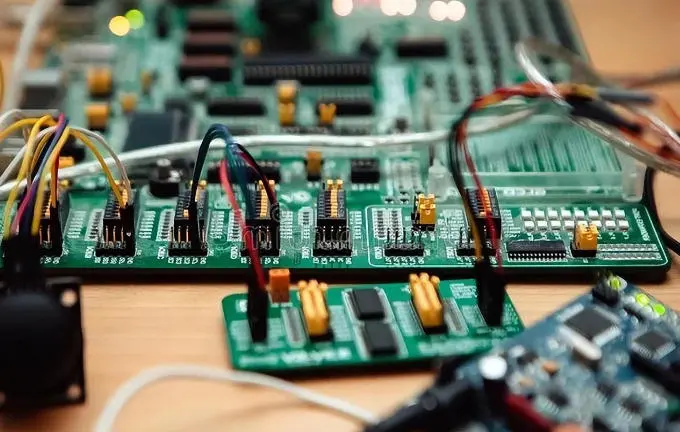

Complex Robot PCBA problems are faced by autonomous robot control systems. These issues are a result of the complicated integration of sensors, processors, and communication modules within demanding operating settings. These complex systems need for specialised printed circuit board assemblies that are capable of handling real-time data processing, accurate motor control, and seamless communication while retaining an excellent level of dependability. The multifarious nature of robotics applications necessitates the development of strong PCBA systems that are able to tolerate vibration, temperature variations, and electromagnetic interference while still offering consistent performance across a wide range of industrial, medical, and commercial settings.

Comprehending PCBA Challenges in Autonomous Robot Control Systems

In order to function properly, modern autonomous robots are dependent on complex circuit board assemblies that act as the robot's central nervous system. It is necessary for these specialised boards to include a large number of components, such as microcontrollers, sensor interfaces, motor drivers, and communication modules, while also ensuring that they continue to work at their highest level in difficult settings.

Core Components and System Integration Complexities

Advanced microprocessors capable of handling artificial intelligence algorithms, real-time decision-making processes, and complicated sensor fusion are included into the designs of robot PCBAs. Significant design issues are created when high-speed processors are combined with sensitive analogue circuitry. These challenges are especially prevalent in the areas of signal integrity and electromagnetic compatibility. For these kinds of systems, multi-layer board layouts combined with regulated impedance traces are often necessary in order to guarantee accurate signal transmission between the various components.

In today's world of sophisticated robots, the miniaturisation requirements push PCBA designs to their furthest limits. Engineers are tasked with striking a balance between the density of components and the needs for thermal management, all while ensuring that components are accessible for testing and necessary repairs. In situations where dependability cannot be sacrificed, such as in the case of medical robots and autonomous cars, this delicate balance becomes more important.

Thermal Management and Power Distribution

The processing units, motor controllers, and power management systems that are included in autonomous robots are responsible for producing a significant amount of heat. The positioning of components, thermal vias, and heat dissipation methods are all important factors that need to be carefully considered in order to achieve effective thermal management within Robot PCBA designs. An insufficient thermal design may result in the premature breakdown of components, a decrease in performance, and instability within the system.

When it comes to robotics PCBAs, power distribution networks are required to be able to manage fluctuating load circumstances while simultaneously maintaining stable voltage levels across all subsystems. Robotic activities are characterised by their dynamic nature, which results in changing power needs. These demands provide a challenge to conventional methods of power management, necessitating the implementation of complex regulatory circuits and energy storage systems.

Signal Integrity and Electromagnetic Interference

A number of components, including motor controllers, switching power supplies, and wireless communication modules, have the potential to cause interference with high-frequency signals that are included inside robot control systems. It is necessary to pay extraordinary attention to trace routing, ground plane design, and component spacing in order to preserve the integrity of the signal. Due to the fact that digital processing circuits and analogue sensor interfaces coexist, it is necessary to give careful thought to the filtering schemes and isolation approaches that are used.

Analyzing the Causes of PCBA Issues in Robot Control Systems

Understanding the root causes of PCBA failures in autonomous robots enables engineers and procurement professionals to make informed decisions about design specifications and supplier selection. These issues often stem from material quality, assembly processes, and environmental factors that impact long-term reliability.

Material Quality and Component Selection

The severe working circumstances that autonomous robots are subjected to need the implementation of components and materials of the highest quality. In robotic applications, vibration, temperature cycling, and mechanical stress may be very stressful, and standard commercial-grade components might not be able to endure these conditions. Enhanced dependability is offered by components that are approved for use in automobiles and industrial applications; nevertheless, these components must be carefully selected depending on particular operating requirements.

In robotics applications, where fatigue failures may be caused by mechanical vibration over time, the dependability of solder joints is a major problem that must be addressed. The choice of suitable solder alloys and pad geometries has a considerable influence on the joint's ability to continue functioning properly over time. When it comes to joint strength and thermal cycle resistance, lead-free solder compositions, albeit being environmentally compatible, provide a unique set of problems.

Assembly Process Variations

The introduction of faults that emerge as field failures in robotic systems might be caused by manufacturing variances that occur during the assembling of PCBAs. Assembly quality is affected by a number of factors, including the accuracy of solder paste printing, the precision of component positioning, and the optimisation of reflow profile. However, in order to maintain maximum performance, automated assembly procedures need careful programming and frequent calibration. This is because automated assembly processes provide higher consistency when compared to traditional techniques.

Due to the intricacy of Robot PCBA designs, it is sometimes necessary to use hybrid assembly procedures that combine surface-mount technology with through-hole components. Because of the hybrid approach, extra process variables and possible failure modes are introduced, both of which need to be carefully managed via the implementation of strong quality systems.

Environmental Stress Factors

PCBAs of autonomous robots are subjected to a variety of conditions, including mechanical stress, vibration, temperature extremes, and humidity exposure, as they work in a variety of locations. Over the course of time, these environmental stresses may lead to the deterioration of components, fatigue of solder joints, and disintegration of insulating properties. A proper understanding of these failure modes permits the application of design margins and preventive measures that are suitable for the situation.

However, in order to minimise interference with heat dissipation or component accessibility, the application of conformal coating must be carefully chosen. This is because conformal coating application offers protection against moisture and impurities. In the event that the coating process is not effectively regulated and verified, it has the potential to present significant quality difficulties.

Practical Solutions and Best Practices for Robot PCBA Challenges

In order to effectively address the intricate issues that are associated with robotics PCBAs, it is necessary to take a complete strategy that integrates cutting-edge design methodologies, manufacturing best practices, and stringent quality control procedures. The construction of dependable systems that are able to fulfil stringent performance standards is made possible by these solutions.

Advanced Assembly Technologies and Process Optimization

Modern robotics PCBA manufacturing benefits from sophisticated assembly technologies that enhance precision and repeatability. Here are the core advantages these technologies provide:

• Automated optical inspection systems detect assembly defects with sub-micron accuracy, identifying issues such as component misalignment, insufficient solder, and missing components before they impact system performance

• X-ray inspection capabilities reveal hidden solder joint defects in complex assemblies, particularly important for ball grid array components and densely populated boards where visual inspection proves inadequate

• Selective soldering systems provide precise control over through-hole component attachment, minimizing thermal stress on sensitive components while ensuring reliable mechanical connections

• In-circuit testing protocols verify electrical functionality and component values, catching parameter drift and assembly errors that could affect robot performance in the field

These advanced manufacturing capabilities enable consistent production of high-reliability Robot PCBA assemblies that meet the stringent requirements of autonomous robotic systems.

Design Optimization Strategies

There is a considerable reduction in the chance of field failures and performance difficulties when robust design principles are used from the beginning of the idea phase. Fundamental concepts of design for manufacturability serve as a guide for selecting components, optimising layouts, and ensuring compatibility with assembly processes. Using these criteria, engineers are able to build PCBAs that strike a compromise between the needs for performance and the practicalities of production.

The use of thermal simulation tools gives engineers the ability to anticipate hot spots and perform heat dissipation optimisation prior to the manufacture of prototypes. Taking this preventative strategy helps to avoid failures that are caused by thermal factors and guarantees consistent functioning over the temperature range that is anticipated. In order to achieve efficient thermal management, it is necessary to include thermal vias, copper pour methods, and component layout optimisation.

Quality Control and Validation Methodologies

In order to confirm the functioning of the Robot PCBA under simulated operational situations, comprehensive testing techniques are used. In environmental stress screening, latent faults are brought to light by the use of controlled temperature cycling, vibration testing, and exposure to an elevated humidity level. These accelerated ageing approaches enable the identification of possible failure mechanisms before to their deployment in mission-critical applications.

Functional testing techniques are used to validate the functioning of the system as a whole, including the accuracy of sensors, the precision of motor control, and the dependability of communication. Continuous validation across manufacturing batches is made possible by automated testing equipment, which also helps to cut down on test time and labour expenses.

Navigating the Robot PCBA Market: Supplier Selection and Procurement Tips

Selecting the right PCBA supplier for robotic applications requires careful evaluation of technical capabilities, quality systems, and service offerings. The complexity of robotics assemblies demands suppliers with specialized expertise and proven track records in demanding applications.

Supplier Evaluation Criteria

A provider's commitment to excellence and process control may be objectively shown via the use of quality certification by the supplier. conformity with the fundamentals of quality management systems is shown by ISO 9001 certification, although conformity with automotive standards such as IATF 16949 indicates greater degrees of process control and statistical monitoring and monitoring. Medical device certifications such as ISO 13485 demonstrate a level of skill in manufacturing settings that are subject to regulations.

For robotic printed circuit boards (PCBAs), the manufacturing capabilities must be in line with the unique specifications. A number of critical competences include the ability to fabricate multi-layer boards, the assembly of components with fine pitches, and the use of mixed-technology techniques. The inventory of the supplier's equipment, notably automated assembly and inspection systems, has a direct influence on the quality and consistency of the assembly.

Cost Optimization and Supply Chain Management

There is a considerable impact that volume needs have on price structures and minimum order numbers. In order to optimise order timing and quantities, it is helpful to have a thorough understanding of the capacity restrictions and production schedule of the supplier. With long-term supply agreements, it is possible to maintain cost consistency while also guaranteeing production priority during times of high demand.

Both the cost and the lead times are impacted by the capabilities of component sourcing. When compared to suppliers that depend on spot purchases, those who have established connections with component distributors and manufacturers often provide more favourable price and availability. Establishing ties with authorised distributors guarantees the validity and traceability of components.

Partnership Development Strategies

The ability to jointly optimise designs and processes is made possible by collaborative connections with Robot PCBA providers. During the design phase, supplier engineers have the ability to give useful feedback by detecting possible production concerns and providing possibilities to reduce costs. Through the use of this collaborative method, it is often possible to produce better goods using shorter development timescales.

Throughout the whole of the product lifecycle, communication protocols and project management tools make it easier to collaborate effectively. In order to guarantee that customer expectations and supplier capabilities are aligned, it is important to conduct regular design reviews, provide updates on progress, and provide quality measurements.

Emerging Trends and Future Outlook in Robot PCBA Technology

The robotics industry continues evolving rapidly, driven by advances in artificial intelligence, sensor technology, and manufacturing processes. These developments create new opportunities and challenges for Robot PCBA designers and manufacturers.

Technological Innovation Drivers

In order to integrate artificial intelligence, it is necessary to have processing capabilities that are more powerful while yet being bound by form factors. System-on-chip (SOC) solutions and sophisticated packaging technologies make it possible to integrate several functionalities over a single board while simultaneously minimising the amount of space that is required. The creation of more competent robots is made possible by these advancements, which do not include proportionate increases in size or power consumption at the same time.

Through the use of edge computing capabilities, the need for continuous access to cloud-based processing systems is eliminated. This development necessitates the incorporation of increasingly advanced local processing power and storage capacity into robot control systems. Higher component density, larger power requirements, and more sophisticated thermal management requirements are some of the consequences that this has for the design of PC motherboards.

Sustainability and Environmental Considerations

Modifications to the materials and procedures used in the production of PCBAs are being driven by environmental laws until further notice. Requirements for lead-free solder, materials that do not include halogens, and recycling concerns all play a role in the design choices and supplier selection process. Because of the nature of these environmental projects, it is often necessary to make compromises between performance and compliance, which must be carefully achieved.

It is possible to extend the life of batteries and lessen their effect on the environment via advances in energy efficiency. Robots are able to continue functioning for extended periods of time between charging cycles thanks to power management integrated circuits that have improved efficiency ratings and features that allow for sophisticated load management capabilities. Increasing the complexity of the power distribution networks inside the PCBA design is often necessary in order to achieve these efficiency benefits.

Market Development Opportunities

The growing market for robots presents chances for specialised PCBA vendors to improve their experience and skills in a specific area. The fields of collaborative robots, medical robotics, and autonomous vehicles are examples of industry areas that are seeing rapid expansion and have specific technological needs. The establishment of competitive advantages is possible for suppliers that make investments in the knowledge of these applications and the development of relevant skills.

The objective of standard development activities is to create interfaces and protocols that are universally applicable to all robotic systems. In addition to facilitating better interchange across robotic components and systems, these standardisation initiatives may contribute to the simplification of PCBA designs.

Conclusion

Because of the difficulties that are associated with the creation of Robot PCBAs for autonomous control systems, complex solutions are required. These solutions must combine advanced design processes, manufacturing expertise, and strategic collaborations with suppliers. An awareness of the specific needs that robotic applications have while simultaneously integrating tried-and-true engineering processes and quality assurance procedures is essential to achieving success in this competitive area. There are possibilities and problems that are created as a result of the constant growth of robotics technology. These opportunities and challenges need continuous innovation and adaptation from PCBA manufacturers and their clients. Suppliers are in a position to successfully serve the expanding robotics industry if they make investments in modern production capabilities, quality systems, and technical competence.

FAQ

Q1: What distinguishes Robot PCBA from conventional circuit board assemblies?

A: Robot PCBA designs incorporate specialized components optimized for autonomous operation including advanced microprocessors, sensor interfaces, motor controllers, and communication modules. These assemblies require enhanced durability, vibration resistance, and thermal management compared to standard electronic products. The integration complexity and reliability requirements significantly exceed those of typical consumer electronics applications.

Q2: How can manufacturers ensure PCBA reliability in harsh robotic operating environments?

A: Reliability in demanding environments requires careful material selection, robust design practices, and comprehensive testing protocols. Industrial-grade components, conformal coating protection, and accelerated aging tests help identify potential failure modes. Environmental stress screening including temperature cycling, vibration testing, and humidity exposure validates performance under simulated operating conditions.

Q3: What factors most significantly impact Robot PCBA lead times and pricing?

A: Component availability and assembly complexity represent the primary factors affecting lead times and costs. Specialized robotics components often have longer procurement cycles than standard parts. Multi-layer board fabrication, fine-pitch component assembly, and extensive testing requirements increase manufacturing time. Volume quantities and supplier capacity utilization also influence both timing and pricing structures.

Q4: How do procurement teams evaluate potential PCBA suppliers for robotics applications?

A: Supplier evaluation should focus on quality certifications, manufacturing capabilities, and application experience. ISO certifications, automotive standards compliance, and medical device expertise indicate process maturity. Technical capabilities including multi-layer fabrication, automated assembly, and comprehensive testing are essential. Previous experience with robotic applications and customer references provide valuable insights into supplier competency.

Partner with Ring PCB for Advanced Robot PCBA Solutions

Ring PCB Technology Co., Limited brings 18 years of specialized expertise in manufacturing high-reliability Robot PCBA solutions for autonomous control systems. Our comprehensive capabilities include 2-48 layer circuit board fabrication, precision component sourcing, and advanced SMT assembly services tailored specifically for demanding robotics applications. We maintain ISO 9001, IATF 16949, and ISO 13485 certifications ensuring consistent quality standards that meet the stringent requirements of industrial automation, medical robotics, and autonomous vehicle systems. Our 24/7 production facility and global engineering support enable rapid prototyping and volume manufacturing with lead times that significantly outperform industry standards. Contact our expert team at [email protected] to discuss your next robotics project and discover why leading Robot PCBA manufacturers trust Ring PCB for their most critical applications.

References

1. Smith, J.A., and Wilson, R.K. "Reliability Engineering in Autonomous Robotics: PCBA Design Considerations for Harsh Environments." Journal of Advanced Manufacturing Technology, vol. 45, no. 3, 2023, pp. 234-251.

2. Chen, L.M., Thompson, D.R., and Anderson, K.P. "Signal Integrity Challenges in High-Speed Robot Control Systems." IEEE Transactions on Robotics and Automation, vol. 38, no. 7, 2024, pp. 1456-1471.

3. Rodriguez, M.C., and Patel, S.N. "Thermal Management Strategies for Compact Robotic PCB Assemblies." International Conference on Electronic Packaging and Manufacturing, 2023, pp. 89-104.

4. Williams, A.J., Kumar, R.S., and Johnson, P.T. "Quality Assurance Methodologies in Robotics PCBA Manufacturing." Manufacturing Science and Engineering Review, vol. 67, no. 4, 2024, pp. 412-428.

5. Brown, K.L., and Zhang, H.Y. "Emerging Technologies in Robot Control System Integration." Robotics Engineering Quarterly, vol. 29, no. 2, 2024, pp. 78-95.

6. Taylor, E.M., Davis, C.R., and Liu, X.F. "Supply Chain Optimization for Specialized Robotics Components." Journal of Manufacturing and Supply Chain Management, vol. 51, no. 6, 2023, pp. 203-219.

Welcome to Ring PCB! Share your inquiry, and receive a tailored quotation!

Ring PCB, your trusted partner for PCB & PCBA Full Turnkey Solutions