When choosing between cutting-edge PCB Get together Administrations and conventional Through-Hole innovation, your choice impacts taken a toll, execution, and fabricating timeline, making professional PCB Assembly Services essential for optimizing cost, performance, and production efficiency. Surface Mount Innovation (SMT) gathering offers predominant component thickness and robotized generation productivity, making it perfect for buyer hardware and high-volume fabricating. Through-hole get together gives uncommon mechanical quality and unwavering quality, especially suited for mechanical applications requiring vigorous associations. The ideal choice depends on your particular plan necessities, component accessibility, and generation volume.

Understanding PCB Assembly Technologies: The Core Differences

Electronic fabricating has advanced significantly over the past decades. Two essential gathering strategies overwhelm today's showcase: Surface Mount Innovation and through-hole get together. Each approach offers particular preferences for diverse applications. Surface Mount Innovation speaks to the advanced standard for PCB creation. Components mount straightforwardly onto board surfaces utilizing patch glue connected through stencils.

This strategy empowers robotized gathering forms and underpins miniaturization patterns in electronic design. Through-hole gathering includes embeddings component leads through bored gaps some time recently fastening. This conventional strategy makes mechanical bonds that withstand extraordinary conditions. Numerous control components and connectors still utilize through-hole mounting for upgraded durability.

Three core differences distinguish these technologies:

- Component mounting approach: Surface mounting versus lead insertion

- Assembly automation level: Highly automated SMT versus manual/semi-automated through-hole

- Board real estate utilization: High-density SMT versus space-consuming through-hole

Manufacturing capabilities vary significantly between approaches, making specialized PCB Assembly Services crucial for ensuring consistent quality, reliability, and performance across different production methods. SMT assembly achieves component placement speeds exceeding 50,000 components per hour using advanced pick-and-place equipment. Through-hole assembly typically processes 1,000-3,000 components hourly due to manual insertion requirements.

Surface Mount Technology: Advantages and Limitations

SMT assembly delivers exceptional performance for modern electronics. Component miniaturization enables complex circuit designs within compact form factors. Automated assembly reduces labor costs while improving placement accuracy to ±0.05mm tolerances.

Key advantages include:

- Superior component density supporting complex designs

- Reduced electromagnetic interference through shorter signal paths

- Lower manufacturing costs for high-volume production

- Enhanced electrical performance at high frequencies

- Compatibility with advanced inspection technologies like X-ray and AOI testing

Quality control benefits from computerized assessment frameworks. Optical review recognizes arrangement mistakes, whereas X-ray examination uncovers covered-up patch joint abandons, ensuring high reliability in professional PCB Assembly Services. These capabilities guarantee imperfection rates underneath 0.2% for experienced producers. SMT confinements influence particular applications. Component substitution requires specialized revamp gear. Warm cycling can stretch patch joints more than through-hole associations. Model get together may demonstrate exorbitant for little amounts due to stencil requirements.

Through-Hole Assembly: Strengths and Drawbacks

Through-hole technology excels in demanding environments requiring mechanical robustness. Component leads inserted through plated holes create reliable connections capable of withstanding vibration, shock, and temperature extremes.

Mechanical advantages include:

- Superior connection strength for power components

- Enhanced reliability in harsh operating conditions

- Simplified component replacement and repair procedures

- Lower equipment investment for small-scale production

- Excellent performance for high-current applications

Testing data demonstrates through-hole joint strength. Pull tests reveal through-hole connections withstand forces 3-5 times greater than equivalent SMT joints. This mechanical advantage proves crucial for automotive electronics and industrial control systems. Manufacturing flexibility benefits small-batch production. Component insertion requires basic equipment, making through-hole assembly accessible for prototype development. Manual assembly enables quick design iterations without significant tooling costs.

Drawbacks include larger board space requirements and limited automation capabilities. Component density remains constrained by hole spacing requirements. Assembly speeds lag significantly behind SMT processes, increasing labor costs for high-volume production. If you need robust mechanical connections for industrial applications or cost-effective prototype development, through-hole assembly delivers proven reliability for power supplies, motor controls, and outdoor equipment.

Application-Specific Selection Criteria

Design requirements drive technology selection more than personal preferences. Understanding application demands helps identify optimal assembly approaches for specific projects. Consumer electronics favor SMT assembly for miniaturization and cost efficiency. Smartphones, tablets, and wearable devices require maximum functionality within minimal space. SMT components enable these compact designs while supporting automated manufacturing.

Industrial applications often combine both technologies strategically. Power components and connectors utilize through-hole mounting for mechanical strength, while control circuits employ SMT for space efficiency. This hybrid approach optimizes performance and reliability.

Environmental considerations influence technology selection:

- Operating temperature range: Through-hole joints better withstand thermal cycling

- Vibration resistance: Mechanical leads provide superior shock tolerance

- Moisture exposure: Both technologies perform well with proper conformal coating

- Chemical resistance: Material selection matters more than assembly method

Production volume affects economic viability. SMT assembly becomes cost-effective for quantities exceeding 1,000 units due to setup costs, highlighting the efficiency and scalability of professional PCB Assembly Services. Through-hole assembly remains economical for small batches and prototypes requiring minimal tooling investment. If you need guidance selecting appropriate technologies for your specific application, experienced PCB assembly providers offer Design for Manufacturing consultation to optimize component selection and assembly methods.

Quality Control and Testing Considerations

Quality assurance requirements vary between assembly technologies. Each method demands specific inspection approaches and testing procedures to ensure reliable performance. SMT quality control leverages advanced automation. Solder paste inspection verifies deposit volume and placement accuracy before component mounting. Automated Optical Inspection (AOI) examines component orientation and solder joint formation at speeds exceeding 1,000 joints per minute.

X-ray inspection reveals hidden defects in SMT assemblies. Ball Grid Array (BGA) components and dense connector areas benefit from X-ray examination to identify void formation and insufficient solder volumes. Modern X-ray systems detect defects as small as 25 microns. Through-hole inspection relies heavily on visual examination and electrical testing. Solder joint quality assessment requires trained inspectors familiar with IPC-610 standards. Wave soldering defects include insufficient fill, bridging, and component damage from excessive heat exposure.

Functional testing approaches differ significantly:

- In-Circuit Testing (ICT): SMT assemblies support bed-of-nails testing for component verification

- Boundary Scan Testing: Digital components enable comprehensive connectivity testing

- Flying Probe Testing: Flexible approach suitable for both technologies

- Functional Testing: End-product performance validation regardless of assembly method

Rework capabilities affect long-term reliability. SMT component removal requires precise temperature control to prevent board damage. Through-hole components allow easier replacement with basic soldering tools, reducing repair costs and downtime.

Future Trends and Technology Evolution

Electronic manufacturing continues evolving toward increased automation and miniaturization. Understanding industry trends helps make informed decisions for long-term product strategies. SMT technology advancement focuses on smaller component packages and higher placement accuracy. 01005 components (0.4mm × 0.2mm) push miniaturization limits while maintaining assembly reliability. Advanced placement equipment achieves ±15-micron accuracy for these ultra-small components.

Through-hole technology adapts through specialized applications. Power electronics increasingly require robust connections capable of handling higher currents and voltages. Press-fit connectors eliminate soldering while maintaining mechanical reliability for high-reliability applications.

Hybrid assembly approaches gain popularity for complex designs. Mixed-technology boards optimize performance by selecting appropriate assembly methods for different circuit sections. Power management utilizes through-hole components while digital processing employs high-density SMT layouts.

Material innovations affect both technologies:

- Lead-free solder alloys improve environmental compliance

- Low-temperature solder pastes reduce thermal stress

- Flexible substrates enable new form factors

- Embedded components integrate passive elements within board layers

Automation expansion reduces cost differences between technologies. Selective soldering systems automate through-hole assembly for medium-volume production. Robot-assisted insertion handles odd-form components efficiently while maintaining placement accuracy.

Conclusion

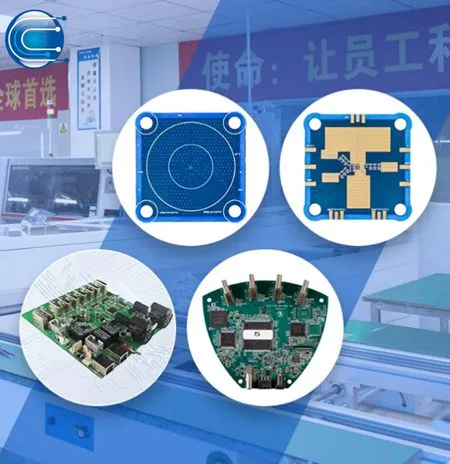

Manufacturing capabilities include 1-24 layer constructions with fine-pitch component assembly services, supporting efficient Small Batch PCB production for prototyping and low-volume orders, complemented by comprehensive PCB Assembly Services to ensure high-quality, reliable outcomes. SMT assembly excels for high-density, cost-effective manufacturing of consumer electronics, while through-hole technology provides superior mechanical reliability for industrial and power applications. Many modern designs benefit from hybrid approaches that leverage both technologies strategically.

Successful project outcomes require partnering with experienced manufacturers offering comprehensive capabilities and quality systems. Ring PCB combines advanced manufacturing technology with proven expertise to deliver exceptional results for both assembly methods. Understanding your specific requirements enables optimal technology selection for reliable, cost-effective electronic manufacturing.

Ring PCB: Your Trusted PCB Assembly Services Supplier

Ring PCB delivers comprehensive electronic manufacturing solutions combining decades of expertise with cutting-edge technology. Our integrated approach supports both SMT and through-hole assembly requirements within a single, quality-controlled facility.

Advanced manufacturing capabilities set Ring PCB apart as a leading PCB assembly services manufacturer:

- Precision Engineering: 2-48 layer boards with blind/buried vias, 3/3mil trace/spacing, ±7% impedance control

- Smart Manufacturing: Self-owned facility equipped with LDI laser exposure, vacuum lamination, and flying probe testers

- Quality Excellence: IPC-6012 Class 3 standards with AOI + impedance testing + thermal cycling

- Turnkey Solutions: PCB fabrication + component sourcing + SMT assembly + functional testing

- DFM/DFA Optimization: Expert engineering team reduces design risks and BOM costs

Vertical integration ensures complete supply chain control from raw material procurement through final testing. Triple quality assurance protocols maintain defect rates below 0.2%, significantly outperforming industry averages. Global certifications including ISO9001, IATF16949, and RoHS compliance demonstrate our commitment to excellence. Ready to discuss your next project requirements? Our experienced team provides personalized consultation and competitive quotations for PCB assembly services for sale. Contact us at [email protected] to explore how Ring PCB can accelerate your product development and manufacturing success.

References

1. Harper, Charles A. "Electronic Packaging and Interconnection Handbook." McGraw-Hill Education, 5th Edition, 2020.

2. Lau, John H. "Solder Joint Reliability of BGA, CSP, Flip Chip, and Fine Pitch SMT Assemblies." McGraw-Hill Professional, 2019.

3. Prasad, Ray P. "Surface Mount Technology: Principles and Practice." Chapman and Hall, 3rd Edition, 2021.

4. Turbini, Laura J. "Through-Hole Technology Assembly Handbook." IPC International, 2020.

5. Wilson, Peter R. "PCB Assembly Quality Control: Modern Inspection Techniques." Electronics Manufacturing Press, 2022.

6. Zhang, Michael K. "Cost Analysis in Electronic Manufacturing: SMT vs Through-Hole Economics." Industrial Electronics Quarterly, Vol. 45, No. 3, 2023.