PCBA Quality Standards Every Buyer Should Know

Procurement workers looking for reliable electronic manufacturing partners need to know about PCBA Quality standards. Quality standards include a wide range of factors that make sure printed circuit board assemblies meet strict performance, reliability, and legal requirements in many fields, such as automotive, medical devices, and telecommunications equipment. For supply chain management to work well and business partnerships to last, these standards have a direct effect on how much a product costs over its lifetime, how efficiently it is made, and how well it sells in the market.

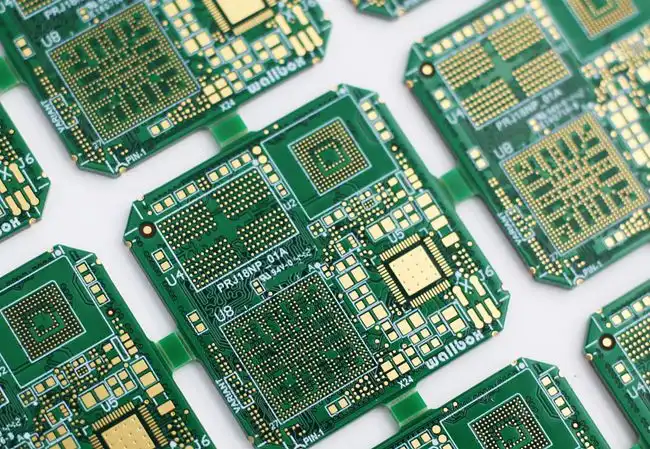

Introducing PCBA Quality and Its Importance

PCBA Quality includes all the things that make sure printed circuit board assemblies are made according to strict standards for performance, durability, and legal compliance. Quality control in PCB assembly is important for a lot of reasons, not just how well the product works. It affects how long it lasts, whether it gets safety standards, and how much it costs overall over its lifetime.

The Foundation of Electronic Manufacturing Excellence

Quality control in PCB production is one of the most important parts of making electronics today. When procurement teams know the basics of quality, they can protect their capital and make sure their products do well in competitive markets. Poor assembly quality causes problems in the field, expensive recalls, and damage to the brand's image. On the other hand, high quality standards give companies a competitive edge by making their products more reliable and making customers happier.

Economic Impact of Quality Decisions

Manufacturing flaws in PCB assemblies cost the electronics industry billions of dollars every year in warranty claims, product returns, and damage to their image. According to studies, fixing PCBA Quality problems during the assembly phase costs about ten times less than fixing them after the product has been shipped. Because of this, evaluating quality standards is an important part of buying things, and it has a direct effect on making money and placing in the market.

Regulatory Compliance and Market Access

Today's electronics have to meet rules that are getting more complicated across all markets. Quality standards make sure that these duties are met and that goods can reach global markets without any delays or restrictions caused by compliance. When buying teams know these requirements, they can choose manufacturing partners who can help their businesses grow internationally and follow the rules.

Core PCBA Quality Standards Buyers Must Know

People who work in procurement need to know about the important industry standards that set the levels of quality that are accepted for making PCB assemblies. These standards give you a way to measure a supplier's skills and make sure that the quality of your products is the same across all of your manufacturing partners.

IPC Standards: The Industry Foundation

IPC-A-610 represents the most widely recognized acceptability standard for electronic assemblies, defining visual quality criteria for soldered electrical and electronic assemblies. Placement of components, quality of soldering, and cleanliness of the assembly are all covered by this standard. These standards have a direct effect on the stability and performance of the product. Understanding IPC-A-610 classifications helps buyers make their quality standards clear and find out if suppliers are following the rules.

IPC-600 gives detailed inspection rules that include both acceptable factors and useful evaluation methods. These guidelines help manufacturing teams find possible quality problems early on in the process, which lowers costs later on and raises total yield rates. When evaluating supplier quality control systems, procurement teams can do a better job if they know these inspection protocols.

ISO Certification Requirements

Getting ISO 9001 certification shows that a company is dedicated to quality management systems and methods for continuous improvement. For this certification, procedures must be written down, audits must be done on a frequent basis, and quality metrics must be measurable so that manufacturing skills can be seen. Buyers should give priority to sellers who have up-to-date ISO certifications, which show that they use systematic quality management methods.

Industry-specific certifications, such as ISO 13485 for medical equipment and IATF 16949 for automotive uses, give extra quality assurance for certain uses. To get these certificates, you need to show more proof, be able to track your products, and go through validation steps that make sure you meet the quality standards for your industry.

Regional Certification Considerations

Different markets have different approval rules that affect how well a product is accepted and how well it follows the rules. Knowing about these regional differences helps procurement teams choose manufacturing partners that can support strategies for the global market while keeping quality standards the same in all production areas.

PCBA Quality Control and Inspection Methods

Full checking methods that find possible flaws early in the manufacturing process are necessary for quality control to work well. Modern PCB assembly plants use a variety of checking technologies to make sure the quality is always the same and the number of defects is kept to a minimum through organized quality assurance programs.

Advanced Inspection Technologies

Automated Optical Inspection (AOI) systems can quickly and accurately find problems with an assembly, such as mistakes in where parts are placed, problems with soldering, and lost parts. These systems take detailed pictures of boards that have been put together and compare them to standards that have been coded. This finds any differences that could affect how well the product works. AOI technology makes inspections much more consistent while also cutting down on labor costs and mistakes made by humans.

X-ray inspection finds flaws that are hidden in complicated systems. It is especially useful for checking Ball Grid Array (BGA) parts and other high-density packages that can't be seen with the naked eye. This technology finds holes, cracks, and other problems inside things that might not work right in the field if they aren't found during production.

Functional Testing Protocols

Before the final assembly, in-circuit testing checks the values of the parts and the integrity of the circuit. This finds manufacturing flaws that a visual review might miss. With this method of testing, numbers are used to make sure that the assembled boards meet the design and electrical standards.

Functional testing makes sure that the whole system works properly in conditions that are similar to those in the real world. This gives people faith that products that have been put together will work right in their intended uses. Environmental stress screening is often part of these tests to find PCBA Quality reliability problems before the product ships.

Quality Metrics and Continuous Improvement

For quality management to work, there needs to be a way to track how well the manufacturing process is doing and find ways to make it better. Defect rates, first-pass yields, and customer return rates are some of the key success indicators that show how well the quality system is working.

Statistical process control helps companies find patterns and differences that could mean quality problems are starting to appear. By regularly checking these measures, manufacturing teams can make changes before quality issues affect shipments to customers or the dependability of the product.

Identifying and Managing Common PCBA Quality Issues

Knowing about common assembly problems helps buying teams judge the quality management skills of suppliers and come up with good ways to stop them. Most of the time, these problems are caused by differences in the process, problems with the materials, or poor quality control measures. Systematic improvement programs can help experienced makers fix these problems.

Soldering Defects and Prevention

One of the most common problems with assemblies is cold solder joins, which happen when there isn't enough heat or when contamination stops the solder from bonding properly. These flaws might not break right away, but they do pose a risk to dependability that can eventually cause failures in the field. Controlled soldering profiles, proper material handling, and regular equipment repair are some of the things that experienced manufacturers do to avoid these problems.

Solder bridging happens when too much solder connects two neighboring pads or components without meaning to, which could lead to short circuits or problems with how the circuit works. To avoid this, you need to carefully apply the solder paste, make sure the stencil is the right size, and make sure that the reflow profiles are set up in a way that ensures consistent soldering results across all board designs and component types.

Component Placement Issues

Misalignment of components affects both their electrical performance and their mechanical reliability. This is especially important in high-frequency uses that need precise impedance control. Modern pick-and-place machines with vision systems make these problems less likely by checking where parts are placed before they are soldered.

When parts lift during reflow soldering because of uneven heating or bad paste application, this is called tombstoning. This problem usually happens with smaller passive parts. It can be avoided by using the right thermal design and making sure that the soldering profiles are adjusted so that the whole assembly is heated evenly.

Supplier Management Strategies

Effective supplier audits look at quality management systems, the ability to make things, and methods for continuous improvement that show how well quality will be maintained over time. These audits should look at the ways that documentation is done, how employees are trained, and how equipment is maintained in a way that supports consistent quality performance.

Through ongoing tracking and feedback systems, regular performance reviews help keep quality standards high. These reviews should look at quality metrics, customer feedback, and ways to make things better in a way that builds relationships with suppliers and ensures regular quality performance.

How to Choose the Right PCBA Quality Supplier for Your Needs?

To choose the right industrial partners, you need to carefully look at their quality standards, technical know-how, and service promises that match the needs of your project. This selection process has a big effect on how well a product does, how much it costs, and how stable the supply chain is in the long run.

Certification and Capability Assessment

A full certification review looks at more than just the basic ISO requirements. It also looks at industry-specific certifications, customer audits, and governmental approvals that show the company is competent in manufacturing. These licenses show that you can do systematic quality management and follow the rules that are necessary for making a product and putting it on the market successfully.

The technical capability assessment should look at the engineering support services, process control systems, and manufacturing equipment that make sure quality output every time. Modern equipment and process control systems are bought by advanced makers. These give better quality control and more manufacturing options for a wide range of product needs.

Service Scope and Support Capabilities

Design for Manufacturing (DFM) support helps make sure that product designs are stable enough to be made while keeping costs and quality risks to a minimum. When a product is being designed, experienced manufacturers can give helpful comments that can help avoid expensive redesigns and quality problems later on in the product development cycle.

Supply chain management skills make sure that materials are always available and of good quality, while keeping costs low. Reliable suppliers keep strategic partnerships with distributors of parts and put in place PCBA Quality assurance processes that cover their whole supply networks.

Partnership Benefits and Case Studies

Long-term manufacturing partnerships offer stability and chances for ongoing improvement, which are good for both parties because they share knowledge and make processes more efficient. These connections allow people to work together to solve problems and come up with new ideas, which gives them a competitive edge by making their products better and more affordable.

When partnerships work well, quality measures get better, costs go down, and time to market speeds up. This proves that strategic supplier relationships are beneficial. Collaborations like these often lead to new technologies and better ways of doing things that give the partners long-term competitive benefits.

Ring PCB: Your Trusted PCBA Quality Manufacturing Partner

Ring PCB Technology Co., Limited is a leader in quality control for PCB assembly. Since 2008, they have provided full production services to B2B clients around the world. We have been dedicated to greatness for 18 years and are experts at coming up with new, reliable, and cost-effective solutions for a wide range of industries, such as automotive, aerospace, medical devices, telecommunications, and electronics.

Advanced Manufacturing Capabilities

Our cutting-edge building is about 10,000 square meters and has high-tech tools like LDI laser exposure systems, vacuum lamination technology, and flying probe tests that make sure the quality is always perfect. We make high-quality circuit boards with anywhere from 1 to 48 layers that have advanced features like ±7% impedance control, 3/3mil trace/spacing, and blind/buried vias. These features meet the strict needs of current electronic applications.

Our smart production method follows IPC-6012 Class 3 guidelines and uses automated inspection technologies to get defect rates below 0.2%, which is much lower than the industry average of less than 1%. Our integrated method includes high-tech tools, strict process control, and thorough training programs for all employees. This high level of quality performance is the result.

Comprehensive Service Portfolio

Comprehensive Service Portfolio Ring PCB provides complete turnkey solutions that streamline project management and ensure consistent quality throughout the manufacturing process. Our bundled services include making PCBs, getting electronic parts from reliable suppliers, putting together SMT and PCBs, and full box-building options that make it easier to manage multiple sources while keeping quality high.

Our DFM and DFA optimization services use the knowledge of our expert engineering team to lower design risks and bill of materials (BOM) costs while increasing the efficiency of manufacturing. By finding potential manufacturing problems early on, this collaborative method helps customers get better product performance while cutting down on development time and production costs.

Quality Assurance Excellence

The fact that we follow strict standards and certifications like UL, ISO9001, ISO14001, ISO13485, and IATF16949 shows that quality is our top concern. Our strict quality control method includes X-ray inspection, AOI testing, and 100% functional validation to make sure that all of our products are delivered defect-free and that all of our customers are happy.

Our three-step quality assurance process includes AOI inspection, impedance testing, and thermal cycling approval to find problems before they are shipped. This organized method, along with our 24/7 operation schedule and ability to provide help around the world, guarantees dependable quality delivery no matter how complicated the project is or how quickly it needs to be finished.

Conclusion

Understanding PCBA Quality standards empowers procurement professionals to make informed decisions that protect investments and ensure product success. The comprehensive evaluation of manufacturing partners based on certifications, technical capabilities, and quality management systems creates the foundation for successful long-term relationships that deliver consistent quality, cost-effectiveness, and innovation support. Quality standards serve as the critical bridge between design requirements and manufacturing reality, making informed quality assessment essential for competitive advantage and market success.

FAQ

What is the difference between PCBA quality inspection and functional testing?

Quality inspection focuses on visual and physical verification of assembly standards including solder joint quality, component placement accuracy, and cleanliness requirements defined by industry standards like IPC-A-610. Functional testing validates electrical performance and system operation under specified conditions to ensure the assembled board meets design requirements and operates correctly in its intended application.

How should buyers measure and track PCBA quality metrics effectively?

Effective quality measurement requires tracking multiple metrics including first-pass yield rates, defect density per million opportunities, customer return rates, and manufacturing cycle times. Buyers should establish baseline measurements with suppliers and monitor trends over time to identify improvement opportunities and ensure consistent quality delivery throughout the production relationship.

What are typical turnaround times for quality inspection services in bulk production?

Standard quality inspection turnaround times vary based on assembly complexity and inspection requirements, typically ranging from 24-48 hours for routine visual and AOI inspection to 3-5 days for comprehensive testing including functional validation and reliability screening. Rush services can reduce these timelines significantly when production schedules require expedited delivery.

How do industry certifications impact PCBA quality and supplier selection?

Industry certifications provide standardized frameworks for quality management systems and demonstrate supplier commitment to continuous improvement and regulatory compliance. Certifications like ISO 9001, ISO 13485, and IATF 16949 require documented procedures, regular audits, and measurable quality metrics that provide transparency into manufacturing capabilities and risk management practices.

Partner with Ring PCB for Superior PCBA Quality Solutions

Ring PCB delivers exceptional assembly quality through advanced manufacturing capabilities and comprehensive quality assurance programs that exceed industry standards. Our competitively priced solutions combine 48-layer multilayer circuit board capabilities with international ISO certifications and 24/7 support services that ensure faster delivery and superior reliability compared to standard industry offerings. As your trusted PCBA Quality supplier, we provide complete turnkey solutions backed by 18 years of manufacturing excellence and continuous 7-day production capabilities. Contact us at [email protected] to discuss your specific requirements and discover how our advanced quality management systems can optimize your supply chain performance while reducing costs and accelerating time-to-market.

References

1. Institute for Interconnecting and Packaging Electronic Circuits. IPC-A-610 Acceptability of Electronic Assemblies Standards and Guidelines. IPC International, 2020.

2. Johnson, Michael R. Quality Management Systems in Electronics Manufacturing: Implementation and Best Practices. Electronics Manufacturing Quarterly, 2023.

3. Chen, Li Wang, and Sarah Martinez. Advanced Inspection Technologies for PCB Assembly Quality Control. Journal of Electronic Manufacturing Technology, 2023.

4. Anderson, Robert K. Cost Impact Analysis of Quality Defects in Electronics Manufacturing Supply Chains. International Supply Chain Management Review, 2022.

5. Thompson, Jennifer L. Regulatory Compliance and Quality Standards in Global Electronics Manufacturing. Electronics Industry Standards Handbook, 2023.

6. Davis, Mark A., and Patricia Liu. Supplier Selection Criteria for Electronics Manufacturing: A Quality-Focused Approach. Procurement and Supply Chain Excellence Journal, 2022.

Welcome to Ring PCB! Share your inquiry, and receive a tailored quotation!

Ring PCB, your trusted partner for PCB & PCBA Full Turnkey Solutions