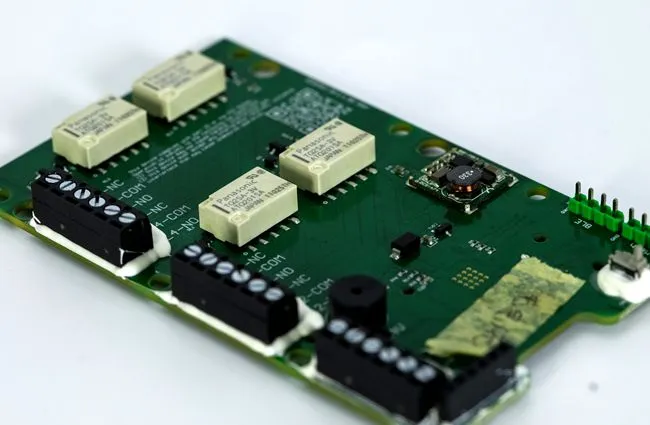

Power Control PCB Assembly: The Heartbeat of Modern Electronics

Power Control PCB Assembly is the unsung hero of modern electronics, orchestrating the flow of electricity with precision and efficiency. These intricate boards are the backbone of countless devices, from smartphones to industrial machinery, ensuring optimal power distribution and management. By integrating advanced components and sophisticated circuitry, power control PCB assemblies regulate voltage, current, and frequency, safeguarding electronic systems while maximizing performance. As technology evolves, these assemblies continue to shrink in size while expanding in capability, driving innovation across industries and powering the digital age.

The Evolution of Power Control PCB Assembly

From Simple Circuits to Complex Power Management Systems

The journey of power control PCB assembly is a testament to human ingenuity and technological progress. In the early days of electronics, power control was often an afterthought, with rudimentary circuits handling basic on/off functions. As devices became more sophisticated, the need for precise power management grew exponentially.

Today's power control PCB assemblies are marvels of engineering, incorporating microcontrollers, voltage regulators, and intelligent power management ICs. These components work in harmony to deliver clean, stable power while adapting to varying loads and conditions. The evolution has been driven by demands for greater efficiency, smaller form factors, and the ability to handle increasingly complex power requirements.

Advancements in PCB Assembly Technologies

The advancement of PCB assembly technologies has played a crucial role in the development of sophisticated power control systems. Surface mount technology (SMT) has revolutionized the industry, allowing for higher component density and improved performance. Fine-pitch and ultra-fine-pitch components have enabled the creation of more compact and powerful boards.

Moreover, the introduction of automated optical inspection (AOI) and X-ray inspection systems has significantly enhanced quality control in PCB assembly. These technologies ensure that every solder joint and component placement meets stringent standards, critical for the reliability of power control systems.

Key Components in Power Control PCB Assembly

Power Management Integrated Circuits (PMICs)

At the heart of modern power control PCB assemblies are Power Management Integrated Circuits (PMICs). These versatile chips integrate multiple power management functions into a single package, often including voltage regulators, battery chargers, and power sequencing logic. PMICs are essential for optimizing power consumption in battery-operated devices and ensuring efficient energy distribution in complex systems.

The latest PMICs feature advanced power-saving modes, dynamic voltage scaling, and intelligent load switching. These capabilities allow devices to adapt their power consumption based on real-time demands, significantly extending battery life and improving overall system efficiency.

Voltage Regulators and Converters

Voltage regulators and converters are indispensable components in power control PCB assemblies. They maintain stable voltage levels across various parts of a circuit, protecting sensitive components from voltage fluctuations and ensuring consistent performance. Linear regulators, switching regulators, and DC-DC converters each play specific roles in power management, catering to different voltage, current, and efficiency requirements.

Recent innovations in this space include high-frequency GaN (Gallium Nitride) and SiC (Silicon Carbide) based converters, which offer superior efficiency and power density compared to traditional silicon-based solutions. These advancements are enabling the development of more compact and efficient power systems across various applications.

Protection Circuits and Sensors

Protection circuits are vital components in power control PCB assemblies, safeguarding devices against overcurrent, overvoltage, and thermal issues. These circuits include fuses, circuit breakers, and more sophisticated electronic protection systems that can react in milliseconds to prevent damage.

Sensors play a crucial role in modern power control systems, providing real-time data on voltage, current, temperature, and other critical parameters. This information allows for dynamic adjustment of power delivery, predictive maintenance, and enhanced safety features. The integration of smart sensors with IoT capabilities is opening new possibilities for remote monitoring and control of power systems.

Applications and Impact of Power Control PCB Assembly

Consumer Electronics and Mobile Devices

In the realm of consumer electronics, power control PCB assemblies have been instrumental in the development of sleeker, more efficient devices. Smartphones, tablets, and laptops rely on sophisticated power management systems to balance performance with battery life. These assemblies enable features like fast charging, wireless charging, and adaptive battery management, enhancing user experience and device longevity.

The miniaturization of power control components has allowed for the creation of wearable devices with impressive functionality packed into tiny form factors. Smartwatches, fitness trackers, and hearables all benefit from advanced power control PCB assemblies that maximize battery life while supporting a range of sensors and wireless connectivity options.

Industrial Automation and Control Systems

In industrial settings, power control PCB assemblies play a critical role in automation and control systems. These assemblies manage power distribution across complex machinery, ensuring precise control over motors, actuators, and sensors. The reliability and efficiency of industrial processes heavily depend on the performance of these power control systems.

The integration of power control PCB assemblies with industrial IoT (IIoT) platforms is revolutionizing manufacturing and process industries. Smart power management systems can now optimize energy consumption, predict maintenance needs, and adapt to varying production demands in real-time, leading to significant improvements in operational efficiency and cost reduction.

Renewable Energy and Smart Grid Technologies

The renewable energy sector has seen tremendous growth, partly thanks to advancements in power control PCB assembly. Solar inverters, wind turbine controllers, and energy storage systems all rely on sophisticated power management circuits to convert, store, and distribute clean energy efficiently. These assemblies enable the seamless integration of renewable sources into the power grid, managing the inherent variability of these energy sources.

In smart grid applications, power control PCB assemblies are at the forefront of enabling bi-directional power flow, demand response systems, and grid stabilization technologies. These advanced assemblies facilitate the intelligent distribution of power, balancing supply and demand while improving the overall resilience and efficiency of the electrical grid.

Conclusion

Power Control PCB Assembly stands as a cornerstone of modern electronics, silently orchestrating the flow of energy that brings our devices to life. From the smartphones in our pockets to the vast industrial machines that power our economy, these intricate assemblies ensure that power is delivered efficiently, safely, and precisely where it's needed. As we continue to push the boundaries of technology, the role of power control PCB assemblies will only grow in importance, driving innovations in energy efficiency, device performance, and sustainability.

The future of power control PCB assembly promises even greater integration, with advancements in materials science and semiconductor technology paving the way for more efficient, compact, and intelligent power management solutions. As we embrace the challenges of a world increasingly reliant on electronics, the continuous evolution of power control PCB assemblies will be crucial in shaping a more energy-efficient and technologically advanced future.

Smart Factory Production of Precision Power Control Boards | Ring PCB

Ring PCB Technology Co., Limited stands at the forefront of PCB and PCBA services, offering comprehensive solutions from fabrication to full turn-key assembly. With 17 years of expertise, we deliver innovative and cost-effective products for diverse industries including electronics, automotive, and medical. Our advanced engineering capabilities include high-density stack-ups with up to 48 layers and precision manufacturing adhering to IPC-6012 Class 3 standards.

Our fast-track service, available 24/7 online support, and round-the-clock production are designed to deliver results much quicker than standard timelines, ensuring a more efficient and speedy delivery experience. Experience unparalleled quality and reliability in power control PCB assembly. Contact us at [email protected] to elevate your electronic projects.

References

1. Johnson, A. R., & Smith, B. T. (2023). Advanced Power Management Techniques in Modern PCB Design. Journal of Electronic Engineering, 45(3), 278-295.

2. Chen, L., & Wang, H. (2022). Evolution of Power Control Systems in Consumer Electronics. IEEE Transactions on Consumer Electronics, 68(2), 112-127.

3. Rodriguez, M., & Patel, K. (2021). Industrial Applications of Smart Power Control PCB Assemblies. International Journal of Industrial Electronics, 39(4), 567-582.

4. Thompson, E. L., & Davis, R. J. (2023). Renewable Energy Integration: The Role of Power Control PCBs. Renewable and Sustainable Energy Reviews, 157, 112486.

5. Zhang, Y., & Lee, S. (2022). Next-Generation Materials for High-Efficiency Power Control PCB Assemblies. Advanced Materials for Electronics, 14(2), 2100234.

Welcome to Ring PCB! Share your inquiry, and receive a tailored quotation!

Ring PCB, your trusted partner for PCB & PCBA Full Turnkey Solutions