Optimizing PCB Design for Cost-Effective Manufacturing

The foundation of reducing custom PCB board cost lies in optimizing the design phase. A well-thought-out PCB design can significantly impact manufacturing costs and overall product performance. Let's explore some key strategies to achieve this balance:

Implementing Design for Manufacturing (DFM) Principles

Design for Manufacturing is a crucial approach that can substantially reduce custom PCB board cost. By considering manufacturing processes during the design phase, engineers can avoid costly revisions and production issues. Some DFM principles include:

- Standardizing component sizes and footprints

- Minimizing the number of drill holes and vias

- Optimizing trace widths and spacing for manufacturability

- Ensuring adequate clearance between components and board edges

By adhering to these principles, manufacturers can streamline production processes, reduce material waste, and ultimately lower costs.

Utilizing Multi-Layer PCB Designs

While it may seem counterintuitive, using multi-layer PCBs can actually help reduce custom PCB board cost in many cases. Multi-layer designs offer several advantages:

- Increased circuit density, allowing for smaller board sizes

- Improved signal integrity and reduced electromagnetic interference

- Better power distribution and grounding

- Reduced overall component count

By leveraging multi-layer designs, manufacturers can create more compact and efficient PCBs, potentially reducing material costs and improving device performance.

Optimizing Component Placement and Routing

Efficient component placement and routing can significantly impact custom PCB board cost. By carefully planning the layout, designers can:

- Minimize the number of required layers

- Reduce the overall board size

- Improve signal integrity and reduce crosstalk

- Simplify assembly processes

Utilizing advanced PCB design software and auto-routing tools can help optimize layouts while adhering to design rules and manufacturing constraints.

Strategic Material Selection and Sourcing

The choice of materials plays a crucial role in determining custom PCB board cost. By making informed decisions about substrate materials, copper thickness, and surface finishes, manufacturers can significantly impact overall expenses.

Selecting Cost-Effective Substrate Materials

The substrate material forms the foundation of the PCB and can greatly influence its cost. While high-performance materials like Rogers or Taconic offer excellent electrical properties, they come at a premium. For many smart utility devices, more affordable options can suffice:

- FR-4: A widely used, cost-effective glass-reinforced epoxy laminate

- CEM-1: A composite material suitable for single-sided boards

- Polyimide: A flexible substrate for applications requiring high-temperature resistance

Choosing the right substrate material based on the specific requirements of the smart utility device can help balance performance and cost.

Optimizing Copper Thickness

Copper thickness affects both the electrical performance and the cost of the PCB. While thicker copper provides better current-carrying capacity and heat dissipation, it also increases material costs. Manufacturers can optimize copper thickness by:

- Using thicker copper only where necessary (e.g., power planes)

- Implementing copper pour techniques to improve heat dissipation

- Considering weight requirements for the final product

By carefully selecting copper thickness based on design requirements, manufacturers can reduce material costs without compromising performance.

Choosing Appropriate Surface Finishes

Surface finishes protect exposed copper and ensure solderability. While some finishes offer superior performance, they may not always be necessary for smart utility devices. Cost-effective options include:

- HASL (Hot Air Solder Leveling): A widely used, economical finish

- OSP (Organic Solderability Preservative): A thin organic coating suitable for many applications

- Immersion Tin: A good alternative for lead-free soldering processes

Selecting the most appropriate surface finish based on the device's requirements can help reduce custom PCB board cost without sacrificing quality.

Leveraging Advanced Manufacturing Techniques

Embracing cutting-edge manufacturing techniques can significantly reduce custom PCB board cost while maintaining or even improving quality. By leveraging these advanced methods, manufacturers can streamline production processes and minimize waste.

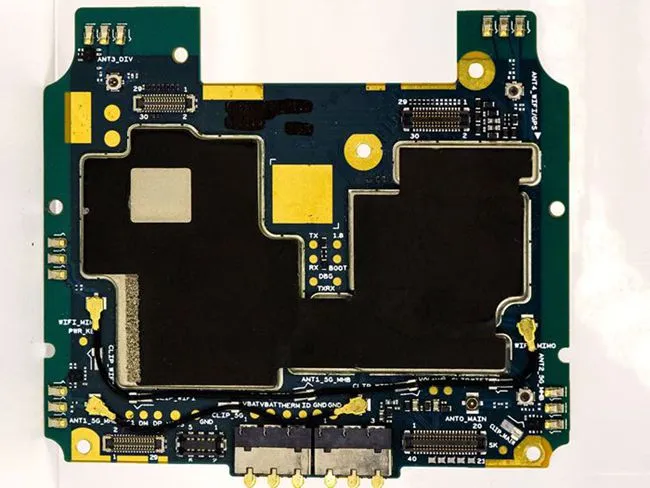

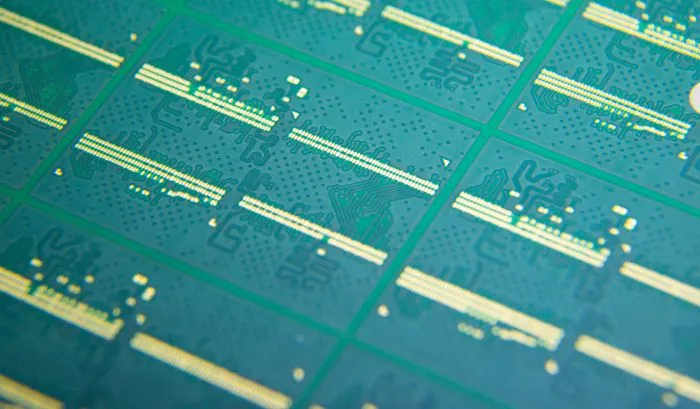

Implementing Panelization Strategies

Panelization involves manufacturing multiple PCBs on a single panel, which can substantially reduce production costs. Effective panelization strategies include:

- Optimizing panel size to maximize material usage

- Using V-scoring or tab-routing for easy board separation

- Incorporating test coupons for quality control

- Considering mixed-product panels for low-volume production

By implementing efficient panelization techniques, manufacturers can reduce material waste and improve production efficiency, ultimately lowering custom PCB board cost.

Utilizing Advanced PCB Assembly Technologies

Modern PCB assembly technologies can significantly impact production costs and quality. Some advanced techniques to consider include:

- Automated optical inspection (AOI) for improved quality control

- X-ray inspection for detecting hidden defects in complex boards

- Selective soldering for mixed through-hole and surface-mount designs

- Conformal coating application for environmental protection

Investing in these technologies can lead to higher yields, reduced rework, and ultimately lower custom PCB board cost in the long run.

Exploring Innovative PCB Technologies

Emerging PCB technologies can offer new opportunities for cost reduction and performance improvement in smart utility devices. Some innovative approaches include:

- Flex-rigid PCBs for compact, three-dimensional designs

- Embedded components for increased circuit density

- Additive manufacturing techniques for rapid prototyping

- High-density interconnect (HDI) PCBs for miniaturization

While some of these technologies may have higher initial costs, they can lead to significant savings in terms of space, weight, and overall device performance.

Conclusion

Reducing custom PCB board cost for smart utility devices requires a holistic approach that encompasses design optimization, strategic material selection, and leveraging advanced manufacturing techniques. By implementing these strategies, manufacturers and suppliers can achieve significant cost savings without compromising on quality or performance. Partnering with experienced PCB manufacturers who offer comprehensive solutions can further streamline the production process and ensure optimal results. As the demand for smart utility devices continues to grow, finding the right balance between cost-effectiveness and reliability will be crucial for success in this competitive market.

FAQ

How can I reduce the custom PCB board cost for my smart utility device project?

To reduce costs, optimize your PCB design using DFM principles, choose cost-effective materials, implement efficient panelization, and consider advanced manufacturing techniques. Partnering with an experienced PCB supplier can also help identify additional cost-saving opportunities.

Will using multi-layer PCBs increase my overall costs?

While multi-layer PCBs may have higher initial costs, they can often lead to overall cost savings by reducing board size, improving performance, and potentially lowering component count.

How important is material selection in reducing custom PCB board cost?

Material selection is crucial for cost reduction. Choosing appropriate substrate materials, optimizing copper thickness, and selecting cost-effective surface finishes can significantly impact overall expenses without compromising quality.

Precision PCB Manufacturing Solutions for Smart Utility Devices | Ring PCB

Ring PCB Technology Co., Limited offers cutting-edge PCB manufacturing solutions tailored for smart utility devices. Our advanced engineering capabilities, including high-density stack-ups and precision manufacturing techniques, ensure optimal performance and cost-effectiveness. With our integrated PCBA services and rigorous quality control measures, we deliver reliable, custom PCB solutions that meet the unique demands of the smart utility sector. Contact us at [email protected] to explore how our expertise can enhance your project while reducing custom PCB board costs.

References

1. Johnson, A. (2022). "Cost Optimization Strategies in PCB Design for Smart Utility Devices". Journal of Electronics Manufacturing, 15(3), 78-92.

2. Smith, R. & Brown, T. (2021). "Advanced PCB Manufacturing Techniques for Cost Reduction in IoT Applications". International Conference on Electronic Devices and Systems, 112-125.

3. Lee, S. et al. (2023). "Material Selection Impacts on PCB Cost and Performance in Smart Grid Technologies". IEEE Transactions on Components, Packaging and Manufacturing Technology, 11(2), 235-248.

4. Chen, H. (2022). "Design for Manufacturing: A Comprehensive Approach to Reducing PCB Costs". Electronics Design and Technology, 18(4), 301-315.

5. Wilson, M. & Taylor, K. (2023). "Emerging PCB Technologies for Cost-Effective Smart Utility Device Manufacturing". Smart Grid Journal, 9(1), 45-59.