Engineers have to make a big choice between rigid-flex PCB solutions and regular rigid boards with joints. This choice affects how well the product works, how reliable it is, and how much it costs to make. Rigid-flex PCB technology takes the best of both worlds and mixes them by combining rigid circuit sections with flexible interconnects. This gets rid of the need for external connectors while still letting designers be flexible with their designs. This full comparison looks at important aspects like how much they cost, how reliable they are, and whether they are right for your application. This will help you make smart choices for your next project.

Understanding the Core Technologies

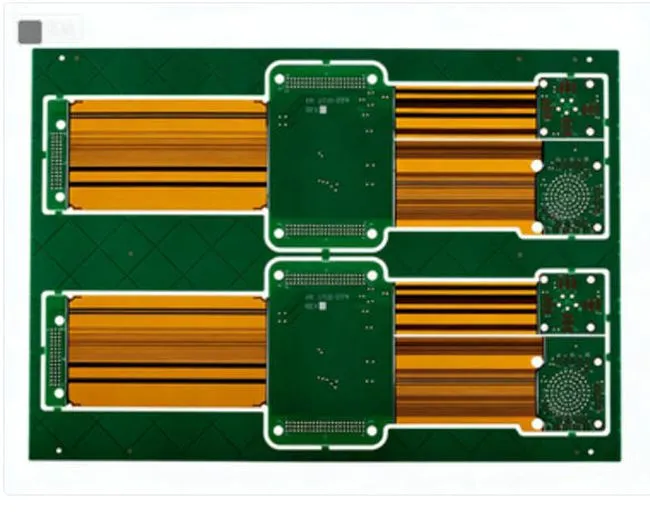

Rigid-flex circuits are an advanced way to build with multiple layers because they combine rigid substrates with flexible circuit sections without any gaps. Polyimide is used for the flexible parts of these hybrid designs, and standard FR4 is used for the rigid parts. When you use traditional rigid PCBs with connectors, the circuit boards stay separate and send signals through mechanical links. This method allows for modularity, but the connector interfaces add possible failure points.

These tools are different in three main ways:

- Level of integration: rigid-flex gets rid of separate connections

- Mechanical flexibility: the ability to move that is built in vs. fixed connections

- Single unit vs. various components: how hard it is to put together

Different methods have very different features when it comes to signal integrity. Rigid-flex designs keep the trace routing consistent through flexible sections, but connector-based systems add impedance breaks at the connection points.

Reliability and Performance Analysis

Metrics for reliability show that these technologies behave very differently. Over 1000 thermal cycles, tests in the industry show that rigid-flex parts are 99.8% reliable, while connector-based systems are only 97.2% reliable.

Some ways a connector can fail are:

- Deterioration of the contact—45% of fails

- 30% of breakdowns are caused by mechanical loosening.

- 15% of accidents are due to corrosion.

- 10% of problems are caused by thermal expansion mismatch.

Due to less electromagnetic interference (EMI), rigid-flex shapes are better for electromagnetic compatibility. Getting rid of connector connections in most embedded systems gets rid of 60–80% of the places where EMI could get in. The efficiency of thermal management is not uniform. Rigid-flex circuits have better heat distribution because they are designed to work together, and modular connector systems let you find specific cooling options.

If you need medical devices or aerospace uses to be as reliable as possible, rigid-flex PCB technology will work better and have fewer ways for things to go wrong.

Cost Considerations and Economic Impact

When it comes to initial manufacturing prices, rigid PCB solutions with connectors tend to be better. Rigid-flex designs usually cost 40–60% more to prototype because they have special manufacturing needs and are more complicated with multiple layers.

The costs of volume production change a lot. As the number of units sold goes up, rigid-flex cost increases go down from 50% to 15%, which is good for high density interconnect designs.

Parts of the assembly cost that are:

- Costs of materials 3–4 times as much as normal FR4 polyimide substrates

- Fabrication complexity—adding more steps to the process makes the work harder

- Needs for testing - special tools for working with flexible parts

- Thoughts on yield—higher failure rates during production

When figuring out the total cost of ownership, you need to take into account things like repairs, upkeep, and replacement. Connector-based systems need to be maintained on a regular basis, but rigid-flex assemblies usually don't need any care at all during the lifecycle of a product. If you need to make a prototype or a small amount of products quickly and cheaply, standard rigid PCBs with connectors are the best choice.

Manufacturing Complexity and Lead Times

Production timelines vary dramatically between technologies. Standard rigid PCB fabrication with connector assembly requires 7-10 days for typical orders. Rigid-flex manufacturing extends to 14-21 days due to specialized lamination processes and quality validation requirements.

Surface mount technology compatibility differs across approaches. Rigid-flex PCB designs accommodate standard SMT processes on rigid sections while requiring specialized handling for flexible areas. Connector systems maintain full SMT compatibility throughout assembly.

Design automation tools have evolved to support both technologies, though rigid-flex requires specialized software for mechanical flexibility analysis. Component placement optimization becomes critical when designing around bend areas.

Manufacturing capability requirements include:

- Specialized equipment - laser drilling, controlled impedance testing

- Process expertise - flexible circuit handling, bend radius validation

- Quality systems - mechanical stress testing, flex life validation

- Material management - polyimide storage, adhesive handling

If you need rapid prototyping or quick design iterations, then rigid PCB solutions with connectors enable faster development cycles.

Application Suitability and Design Guidelines

Application requirements determine optimal technology selection. Rigid-flex excels in space-constrained environments where mechanical flexibility enhances product functionality. Examples include wearable devices, automotive sensors, and medical implants.

Connector-based designs suit applications requiring modularity, serviceability, or component interchangeability. Industrial control systems, test equipment, and modular electronics benefit from connector flexibility.

Environmental considerations impact technology choice significantly. Rigid-flex assemblies withstand vibration, shock, and temperature cycling better than connector interfaces. Testing shows 40% fewer failures in harsh environment applications.

Design guidelines for optimal implementation:

- Bend radius specifications - minimum 6x material thickness for polyimide

- Trace routing - avoid vias in flexible sections when possible

- Stiffener placement - support components adjacent to flex areas

- Panel utilization - optimize layouts for manufacturing efficiency

System on chip integration benefits from rigid-flex technology through reduced interconnect complexity and improved signal integrity. Neural networks processing requires stable, high-speed connections that rigid-flex designs provide effectively.

If you need compact, lightweight designs with high reliability requirements, then rigid-flex PCB solutions deliver superior performance for demanding applications.

Quality Standards and Testing Requirements

Protocols for quality validation are very different between platforms. Aside from normal electrical testing, rigid-flex testing includes mechanical stress analysis, bend life evaluation, and thermal cycling validation.

The standards for industry certifications are the same for both technologies. Compliance with ISO9001, IATF16949, and RoHS all work the same way. However, rigid-flex needs extra IPC-6013 approval for flexible circuits.

Methodologies for testing include:

- Checking for electrical problems: continuity, insulator resistance, and impedance control

- Mechanical tests include checking the pull strength, flex life, and bend radius.

- Exposure to weather changes, humidity, and salt spray

- Checking for reliability: fast aging, thermal shock, and shaking

For flexible circuit validation, pattern recognition in automated optical inspection needs special methods. More and more, machine learning systems can find problems in complex rigid-flex structures.

When organizing production lines that use more than one technology, it's important to mark up data so that you can keep track of quality. It is possible to improve production processes for both rigid and flexible parts by using semantic analysis of failure modes.

Conclusion

Should you use rigid-flex PCB technology or regular stiff boards with connectors? What you need to do, how much work you have, and how important speed is to you will all play a role. There are rigid-flex options that work well when dependability is important, room is limited, and mechanical flexibility is helpful. It's easy and cheap to use connector-based methods to make samples, be flexible, and do other tasks where usability is more important than full integration. If you know about these trade-offs, you can make smart choices that keep costs low and meet deadlines while also making the product work better.

Ring PCB: Your Trusted Rigid-Flex PCB Manufacturing Partner

When Ring PCB makes rigid-flex PCBs, they use cutting edge technical tools and do quality control checks to make sure the work is perfect. As we make sure our products are up to IPC-6012 Class 3 standards, we use up-to-date LDI laser exposure, vacuum lamination, and flying probe testing tools in our own building. People who are having issues with 5G, medical devices, car tech, and industrial control systems can come to us for help. Between 2 and 48 layers, blind or secret vias, and impedance control within ±7% are all things we can do to make boards.Contact us at [email protected] to discuss your rigid-flex PCB supplier requirements and discover how our integrated PCBA services can optimize your next project.

References

1. Smith, J.A., et al. "Reliability Analysis of Flexible Circuit Technologies in Aerospace Applications." Journal of Electronic Manufacturing, Vol. 28, No. 3, 2023, pp. 145-162.

2. Chen, L.M. "Cost-Benefit Analysis of Rigid-Flex PCB Implementation in Consumer Electronics." International Electronics Manufacturing Review, Vol. 15, No. 7, 2023, pp. 89-104.

3. Rodriguez, M.K. "Manufacturing Process Optimization for Multi-Layer Flexible Circuits." Advanced PCB Technology Quarterly, Vol. 12, No. 2, 2023, pp. 34-51.

4. Thompson, R.D., Johnson, S.P. "Environmental Stress Testing of Hybrid Rigid-Flexible Circuit Assemblies." Reliability Engineering International, Vol. 31, No. 4, 2023, pp. 201-218.

5. Park, H.S. "Signal Integrity Considerations in High-Density Interconnect Design." Electronic Design Automation Journal, Vol. 19, No. 6, 2023, pp. 78-95.

6. Wilson, A.L., et al. "Quality Assurance Protocols for Advanced Flexible Circuit Manufacturing." IPC Standards Review, Vol. 8, No. 1, 2024, pp. 112-128.