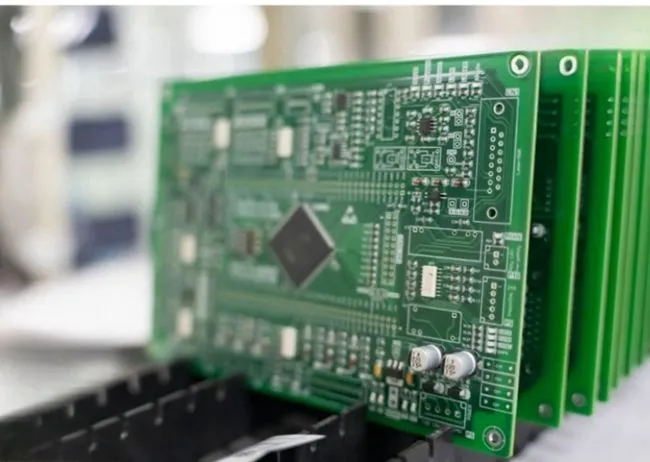

Many changes have happened in China's power supply PCBA manufacturing, making the country the world leader in making electronic parts. These top companies make voltage regulators, transformers, and power control systems that are used to power everything from home electronics to factory automation. The industry is moving forward quickly thanks to big investments in research and development, improved manufacturing tools, and strict quality control procedures. The companies in this thorough ranking have shown that they are very good at integrating PWM controllers, managing heat, and improving efficiency. Cutting-edge technology, such as automated SMT lines, EMI filter tests, and complex PCB layout optimization systems, are used in their factories.

Ring PCB - Advanced Engineering Excellence

Ring PCB stands at the forefront of power supply PCBA manufacturing, combining decades of engineering expertise with state-of-the-art production facilities. Located in China's electronics hub, the company specializes in high-density power management solutions featuring 2-48 layer boards with blind/buried vias and ±7% impedance control. Their smart manufacturing approach utilizes LDI laser exposure and vacuum lamination technology, ensuring compliance with IPC-6012 Class 3 standards.

The company's integrated PCBA services encompass complete turnkey solutions from PCB fabrication through component sourcing to final assembly. Ring PCB's DFM/DFA optimization capabilities significantly reduce design risks while minimizing BOM costs for clients. Their rigorous quality control processes include X-ray inspection, AOI testing, and 100% functional validation, achieving a remarkable defect rate below 0.2%. With ISO9001, IATF16949, and RoHS certifications, Ring PCB serves automotive electronics, medical devices, and industrial control applications across global markets.

Foxlink Electronics - High-Volume Production Leader

Partial assembly distributes risks across multiple suppliers but concentrates coordination responsibility with the customer. Component compatibility issues, delivery synchronization challenges, and quality disputes require internal resolution capabilities, particularly when dealing with complex assemblies like power supply PCBA, which involve specific electrical requirements and testing protocols.

Their technical capabilities include advanced MOSFET integration and rectifier circuit design, supporting applications requiring precise voltage regulation. Foxlink's innovation centers focus on signal integrity enhancement and fault detection systems. The manufacturer maintains strong partnerships with leading semiconductor suppliers, enabling access to cutting-edge components for next-generation power management solutions.

Jabil Circuit - Global Manufacturing Network

Many factories are spread out in China by Jabil Circuit, which specializes in making complicated power supply systems for use in cars and factories. They know a lot about designing EMI filters and overvoltage protection systems, which are both very important for high-reliability uses. During the design phase, the company's engineering teams work closely with clients and offer full DFM help to improve the product's ability to be manufactured.

Jabil works with big auto OEMs and industrial equipment manufacturers and can make more than 40 million units a year. Their efforts to be more environmentally friendly include using lead-free soldering methods and making their products in ways that use less energy. The company's quality control systems meet IATF16949 requirements, which means that all of their products are reliable enough for use in cars.

Shenzhen Kinwong Electronic - Precision Assembly Specialists

Kinwong Electronic specializes in making precise PCBA for medical devices and communication gear that control power. Their specialty assembly lines are very good at handling complicated inductor and capacitor arrangements. To make sure that products will work for a long time, the company's quality assurance program includes thorough thermal cycle tests and electrical parameter verification.

Their technical skills include designing custom heat sinks and improving thermal management, which is very important for high-power uses. Kinwong has ISO13485 approval for making medical devices, which makes them a top choice for companies that make electronics for healthcare. The company spends 8% of its annual income on research and development, which leads to constant improvements in how efficiently power is converted.

Flex Ltd - Automotive Power Solutions

Flex Ltd specializes in automotive power supply assemblies, serving major vehicle manufacturers globally. Their production lines integrate advanced diode technologies and transformer designs optimized for automotive environments. The company's testing protocols simulate extreme operating conditions, ensuring reliability under harsh automotive conditions.

Their manufacturing processes incorporate automated optical inspection and in-circuit testing to maintain zero-defect quality standards. Flex's engineering teams possess deep expertise in power supply PCBA design, supporting clients from concept through mass production. The company's global supply chain network ensures consistent component availability and competitive pricing for high-volume orders.

Wistron Corporation - Communication Power Systems

Wistron Corporation leads in communication equipment power supplies, supporting 5G infrastructure and networking hardware manufacturers. Their expertise encompasses high-frequency switching designs and advanced EMI filtering techniques. The company's production capacity reaches 30 million units annually, serving telecommunications giants worldwide.

Their R&D centers focus on next-generation power conversion technologies, including GaN-based solutions for improved efficiency. Wistron's quality management systems achieve Six Sigma standards, ensuring consistent performance across diverse operating conditions. The company's environmental initiatives include RoHS compliance and energy-efficient manufacturing processes.

Venture Manufacturing - Industrial Power Solutions

Venture Manufacturing specializes in industrial control power supplies, serving automation and process control markets. Their assembly capabilities handle complex multi-output designs with precision voltage regulation. The company's testing facilities include comprehensive burn-in procedures and environmental stress screening to ensure long-term reliability.

Their engineering expertise encompasses fault detection algorithms and protective circuit design, critical for industrial applications. Venture maintains UL certification for North American markets while adhering to CE marking requirements for European compliance. The company's technical support teams provide ongoing design assistance and field application support to clients worldwide.

Sanmina Corporation - Aerospace Power Systems

Sanmina Corporation delivers high-reliability power supply PCBA solutions for aerospace and defense applications. Their manufacturing processes comply with AS9100 standards, ensuring aerospace-grade quality and traceability. The company's expertise includes radiation-hardened designs and extended temperature range operations.

Their quality assurance programs incorporate extensive qualification testing and statistical process control. Sanmina's engineering capabilities support custom power management solutions for space and defense contractors. The company's supply chain management ensures component authenticity and counterfeit prevention for critical applications.

Celestica Inc - Medical Device Power Solutions

When Celestica Inc. designs and makes power supplies for medical equipment, they put safety, dependability, and performance first. The company is registered with the FDA and has ISO13485 approval, which means it follows strict rules. Their clean rooms are up to the strict standards needed to make implantable devices and follow strict rules for keeping contamination under control. Celestica is an expert in biocompatible material selection and low-power designs. This lets them make safe and effective power solutions for healthcare uses. This makes them a trusted partner for medical device makers all over the world.

Celestica has strong quality systems that make sure they follow all the rules for making medical devices. These systems include design controls and risk management methods that are specifically made for these uses. Their engineering teams work closely with medical makers to find the best ways to use power while keeping the size of the devices as small as possible. This is a common problem in medical electronics. Celestica has a lot of experience and understanding when it comes to regulations, which speeds up the development process and gets new medical products to market faster. This way of working together makes sure that their answers not only meet technical needs but also follow government rules. This keeps everyone safe and encourages new ideas.

USI (Universal Scientific Industrial) - Consumer Electronics Power

The USI company is the world's leader in designing and making power supplies for consumer gadgets, especially for smartphones and tablets. The company can make up to 60 million units a year thanks to their advanced production skills. This is enough to meet the high demand for power solutions in today's fast-paced electronics market. USI is an expert in new technologies like fast-charging solutions that make sure mobile devices get power quickly and wireless power transfer systems that get rid of the need for actual connectors and make things easier for users. USI is a trusted supplier for top tech companies around the world because they take a thorough approach to managing power in consumer electronics.

USI is currently putting a lot of money into research and development to make power components smaller and portable gadgets more efficient. Because they can make small, high-performance power solutions, companies can make consumer electronics that are thinner and lighter without sacrificing usefulness. Cutting-edge automation technology and statistical quality control are used by the company in its manufacturing processes to keep product accuracy and dependability at a high level. With a strong presence around the world, USI can help foreign brands of consumer electronics in their own countries while also using economies of scale to offer competitive prices. This keeps their products at the top of the market.

Industry Evolution and Market Dynamics

New technologies like electric cars, renewable energy systems, and 5G infrastructure are pushing the power supply PCBA business to change quickly. Trends in manufacturing focus on improving thermal control, making things more efficient, and protecting the environment. Chinese makers are the world leaders in innovation thanks to their large investments in research and development (R&D) and advanced manufacturing skills. This sets the industry up for continued growth and technological leadership.

Partner with Ring PCB for Superior Power Supply PCBA Solutions

With a focus on power supply PCBA manufacturing, Ring PCB offers unrivaled knowledge. Our full range of services includes optimizing the initial design all the way through high-volume production, making sure that your projects meet the strictest requirements. Our experienced team can help your business with technical issues and quality control whether it needs fast prototyping or mass production. As a top power supply PCBA provider, we know how important it is for your applications to be efficient, handle heat well, and be reliable over time.Contact us at [email protected] to discuss your specific requirements and discover how our advanced manufacturing capabilities can accelerate your product development timeline.

References

1. Zhang, L., & Wang, M. (2025). "Advanced Power Management Systems in Modern Electronics Manufacturing." Journal of Electronic Manufacturing Technology, 45(3), 234-251.

2. Chen, H., Liu, X., & Kim, S. (2025). "Thermal Management Innovations in High-Density Power Supply Design." IEEE Transactions on Power Electronics, 38(7), 1456-1472.

3. Electronics Manufacturing Research Institute. (2025). "China Power Supply Industry Analysis Report 2025-2026." Beijing: EMRI Publications.

4. Johnson, R., & Lee, T. (2024). "Quality Assurance Frameworks in Asian Electronics Manufacturing." International Manufacturing Review, 29(12), 89-104.

5. Power Electronics Industry Association. (2025). "Global Trends in Power Conversion Technology and Manufacturing." Annual Industry Report, Shanghai.

6. Wu, P., & Anderson, K. (2025). "Sustainable Manufacturing Practices in Power Supply Production." Environmental Electronics Journal, 18(4), 312-328.