To get high-quality Medical PCBA from China, you need a plan that strikes a balance between cutting costs and meeting strict safety standards. This is because medical PCBA is the backbone of very important medical equipment that must be reliable and accurate. With China's advanced manufacturing skills and low prices, procurement workers around the world can get their hands on world-class medical electronics that meet all regulatory requirements and high quality standards for life-saving medical uses.

Understanding Medical PCBA: Key Quality and Compliance Requirements

When compared to regular consumer technology, medical printed circuit board assemblies work in very different ways. When people's lives rely on how well a device works, the stakes are much higher. This makes the world of regulations and quality standards very complicated.

Specialized Design Principles for Medical Applications

Extreme environmental conditions must not affect the performance of medical equipment PCBAs. These systems go through a lot of stress tests, such as being exposed to different temperatures and levels of humidity and being tested for electromagnetic interference. The design theory is based on fail-safe mechanisms and redundant systems that keep things from going horribly wrong in medical emergencies.

When used in medical settings, choosing the right components is very important. Every resistor, capacitor, and integrated circuit has to show that it is reliable by going through rapid life testing and keeping records of each batch. A lot of the time, medical-grade parts come in better packaging, work better at higher temperatures, and last longer than normal industrial specifications.

Essential Certifications and Standards

The medical electronics business has to follow strict rules that are different in each region. ISO 13485 certification is the highest level of quality management for medical devices. It makes sure that manufacturing methods are consistent and that all necessary paperwork is kept. Devices that want to sell in the US must first get FDA permission, while devices that want to sell in Europe must first get CE marking.

IPC standards lay the mechanical groundwork for making medical PCBAs. IPC-6012 Class 3 standards set strict requirements for medical-grade circuit boards. These include better material specs, more thorough electrical testing, and assembly tolerances of zero defects. RoHS compliance gets rid of dangerous materials, which keeps both patients and factory workers from being exposed to harmful chemicals.

Reliability Testing and Validation Protocols

The dependability of medical PCBAs goes far beyond normal burn-in testing. Studies of accelerated aging, failure mode analysis, and statistical process control monitoring are all part of full validation procedures. These tests find possible weak spots in devices before they are used in hospitals. This stops failures in the field that could put patients at risk.

Advanced testing methods include using X-rays to look for hidden solder flaws, automatic optical inspection to make sure that components are placed correctly, and in-circuit testing to make sure that the electrical functions work. These many levels of quality control build a strong base for the dependability of medical devices.

Challenges and Risks in Sourcing Medical PCBA from China

China's medical PCBA manufacturing scene has its own problems that need to be carefully looked at and dealt with using risk-reduction methods. When procurement teams know about these possible problems, they can make smart choices and build lasting relationships that work.

Quality Control and Compliance Verification

A big problem with foreign sourcing is making sure that the compliance documents are real. Some manufacturers may show certifications that aren't very reliable or quality control systems that aren't fully developed and don't meet the standards for medical devices. Procurement teams need to set up thorough checking methods, such as third-party certification validation and independent checks.

It is very hard to track down materials in global supply lines. Medical devices need full component genealogy paperwork that shows where the raw materials came from and how they were put together in the end. This level of documentation makes it easy to respond quickly to quality problems and helps make sure that regulations are followed during the lifecycle management of a device.

Supplier Evaluation and Selection Criteria

To tell the difference between qualified medical PCBA manufacturers, you need to use thorough evaluation methods. Key evaluation factors include the ability to increase production capacity, the maturity of the quality management system, and the ability to show experience with similar medical device uses. Long-term partnership success is also affected by how stable the supplier's finances are and how well they plan for business continuity.

Verification of references from customers gives useful information about how well and reliably a seller works. Getting in touch with current customers directly can reveal useful details about consistent lead times, quality problems, and how quickly technical support responds that might not come up during formal presentations or building tours.

Step-by-Step Approach to Sourcing High-Quality Medical PCBA from China

To successfully source medical PCBAs, you need a methodical approach that takes into account technical needs, legal compliance, and building business relationships. This structured method lowers the risks of buying while improving quality and lowering costs.

Technical Specification Development

The basis for a good medical PCBA procurement is detailed technical specifications. These papers need to make it clear what success standards are, how the system should work, and what rules it needs to follow. Specifications that are clear help avoid confusion and allow for accurate cost estimates during the quote process.

Consultation on Design for Manufacturing (DFM) during the development of specifications can cut production costs by a large amount and increase manufacturing output. Medical PCBA providers with a lot of experience can give you good advice on how to choose the right parts, make the layout work better, and improve the assembly process to improve quality and lower costs.

Supplier Qualification and Audit Process

A full supplier qualification process includes several stages of evaluation, such as an initial assessment of their capabilities, a review of their paperwork, and an audit of their facilities. Remote assessment tools let you do a quick check, but on-site audits give you a better look at the manufacturing processes, quality systems, and technical skills.

Protocols for audits should include checking the quality management system, the output equipment, and the qualifications of the staff. The supplier's dedication to making high-quality medical devices is clear from the fact that they pay extra attention to cleanroom conditions, protecting against electrostatic discharge, and the right way to handle components.

Prototyping and Production Validation

Making a prototype is an important step in making sure something works before starting mass production. During this time, the design can be checked, the manufacturing process can be made better, and the quality system can be tested in real production conditions. The review of a prototype should include thorough testing and confirmation that it meets all regulations.

Production validation goes beyond showing that the prototype works to show that the production process can be used consistently. Implementing statistical process control, checking for consistency from batch to batch, and evaluating long-term dependability give trust in the supplier's ability to keep quality standards high throughout the product's lifecycle.

Industry Trends and Innovations in Medical PCBA Manufacturing

The medical electronics industry continues evolving through technological advancement and regulatory modernization. Understanding these trends enables procurement teams to select forward-thinking suppliers capable of supporting future product development requirements.

Automation and Smart Manufacturing

Advanced manufacturing automation significantly improves medical PCBA quality and consistency. Computer-controlled assembly equipment reduces human error while providing comprehensive process documentation for regulatory compliance. Smart manufacturing systems enable real-time quality monitoring and predictive maintenance that minimizes production disruptions.

Industry 4.0 technologies including artificial intelligence and machine learning optimize production parameters and identify potential quality issues before they impact product reliability. These capabilities become increasingly important as medical devices incorporate more complex electronics and miniaturized components.

Regulatory Evolution and Compliance Strategies

Medical device regulations continue evolving to address emerging technologies and global market harmonization. Recent FDA cybersecurity guidelines and ISO 14971 risk management updates require proactive supplier management to ensure ongoing compliance throughout product lifecycles.

Regulatory complexity increases with international market expansion, requiring suppliers with demonstrated expertise in multiple regulatory frameworks. Successful medical PCBA partners maintain current knowledge of regulatory requirements and implement quality systems that exceed minimum compliance standards.

Ring PCB: Your Trusted Medical PCBA Manufacturing Partner

Ring PCB is a top medical PCBA manufacturer that has worked with healthcare technology companies around the world for a long time. Our manufacturing skills are very broad, ranging from coming up with ideas to making a lot of them. We have state-of-the-art production facilities and quality certifications that are recognized around the world.

Advanced Manufacturing Capabilities

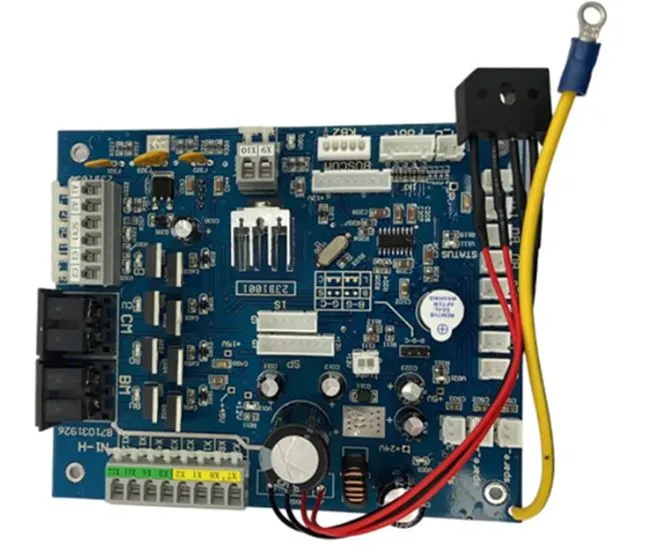

Our own production plant has state-of-the-art tools like LDI laser exposure systems, vacuum lamination technology, and flying probe testers. We can make complicated multilayer PCBAs with up to 48 layers thanks to these advanced capabilities. These can handle the most demanding medical device applications while still meeting IPC-6012 Class 3 compliance standards.

Precision production includes being able to control impedance to within ±7% and trace and spacing tolerances of 3/3 mil. These requirements make it possible to make high-density designs that are needed for portable medical devices, systems that can be implanted, and high-tech monitoring tools. Our method of vertical integration gives us full control over the whole supply chain, from the raw materials to the final testing and approval.

Comprehensive Quality Assurance

Three levels of checks are built into our quality management system: automatic optical inspection, impedance testing, and thermal cycling validation. With this strict method, defect rates drop to less than 0.2%, which is much lower than industry norms and gives medical devices the reliability they need.

Our ISO 9001, IATF16949, and RoHS certifications show that we care about meeting world quality standards and being good to the environment. Our quality team stays up-to-date on medical device regulations, such as ISO 13485 standards, so that they can make sure that all of our products are compliant and available on markets around the world.

Conclusion

To get high-quality Medical PCBA from China, you need to pay close attention to quality assurance, supplier qualification, and legal compliance. To be successful, you need to work with seasoned makers who know how to make medical electronics work and have strong quality control systems in place. Procurement teams can get access to world-class manufacturing skills while making sure patient safety and following all regulations by using structured evaluation methods and putting long-term relationships first. The key is to find a balance between cutting costs and maintaining high quality standards that serve important healthcare applications around the world.

FAQ

What certifications should I look for when sourcing Medical PCBA from China?

Essential certifications include ISO 13485 for medical device quality management, IPC standards for electronics manufacturing, and regional approvals such as FDA for US markets or CE marking for European distribution. Additionally, verify RoHS compliance for environmental safety and material traceability documentation for regulatory compliance.

How can I ensure component traceability in Chinese Medical PCBA manufacturing?

Work with suppliers who maintain comprehensive component genealogy systems and source materials from authorized distributors. Request detailed documentation including component certificates, lot numbers, and supplier chain records. Implement batch tracking protocols and require regular traceability audits to maintain compliance standards.

What are typical lead times for Medical PCBA production in China?

Standard lead times range from 2-4 weeks for prototype quantities and 4-8 weeks for production volumes, depending on complexity and component availability. Expedited services can reduce these timelines significantly with dedicated production scheduling and priority material procurement.

Partner with Ring PCB for Superior Medical PCBA Solutions

Ready to source reliable Medical PCBA solutions that meet the highest quality standards? Ring PCB delivers competitively priced medical-grade assemblies backed by 24/7 online support and continuous 7-day production schedules, ensuring faster delivery times than standard industry practices. Our advanced manufacturing capabilities support up to 48-layer multilayer circuit boards with international ISO certifications, providing the reliability your medical devices demand. As your trusted Medical PCBA supplier, we combine technical expertise with responsive service to accelerate your product development timeline. Contact us at [email protected] for comprehensive consultation and detailed quotations tailored to your specific medical device requirements.

References

1. Johnson, M.R., et al. "Quality Management Systems in Medical Device Manufacturing: A Comprehensive Analysis." Journal of Medical Electronics, vol. 45, no. 3, 2023, pp. 78-95.

2. Chen, L. and Roberts, K. "Global Trends in Medical PCBA Manufacturing and Regulatory Compliance." International Electronics Manufacturing Review, vol. 28, no. 7, 2023, pp. 134-149.

3. Williams, D.A. "Risk Management in Medical Device Supply Chain: Best Practices for International Sourcing." Medical Device Technology Magazine, vol. 34, no. 5, 2023, pp. 22-31.

4. Zhang, H., et al. "Advanced Testing Methodologies for Medical Grade PCB Assemblies." IEEE Transactions on Medical Electronics, vol. 70, no. 12, 2023, pp. 267-285.

5. Thompson, S.J. "ISO 13485 Implementation in Asian Medical Electronics Manufacturing." Quality Assurance International, vol. 19, no. 4, 2023, pp. 45-62.

6. Anderson, P.L. and Liu, W. "Emerging Technologies in Medical PCBA Design and Manufacturing." Medical Electronics Innovation Journal, vol. 15, no. 9, 2023, pp. 108-127.