Comprehending SMT Assembly: Process and Advantages

Surface Mount Technology (SMT) Assembly has revolutionized the electronics manufacturing industry since its introduction in the 1980s. This innovative method involves placing components directly onto the surface of a printed circuit board (PCB), rather than inserting them through holes. The SMT process typically includes several key steps: solder paste application, component placement, and reflow soldering.

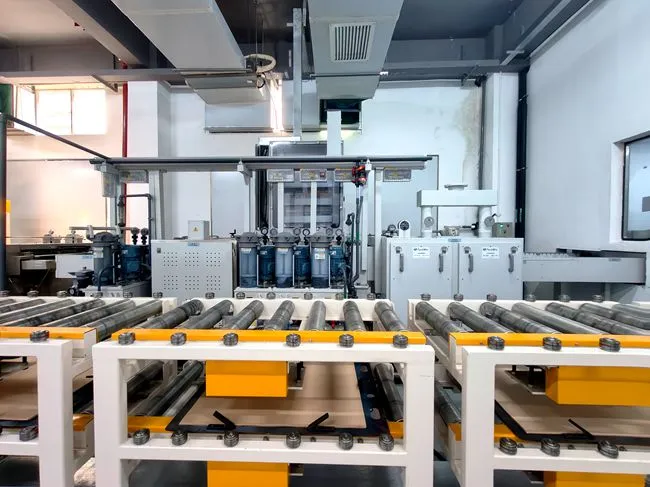

The process begins with the application of solder paste to the PCB using a stencil. This paste, a mixture of tiny solder balls and flux, is precisely deposited onto the board's solder pads. Next, SMT placement machines, often called pick-and-place machines, accurately position components onto the paste-covered pads. These machines can place thousands of components per hour with remarkable precision.

Once all components are in place, the board passes through a reflow oven. The heat melts the solder paste, creating solid electrical and mechanical connections between the components and the board. This process is often followed by inspection and testing to ensure quality and functionality.

Advantages of SMT Assembly

SMT Assembly offers numerous advantages over traditional through-hole methods:

- Miniaturization: SMT components are typically much smaller than their through-hole counterparts, allowing for higher component density and smaller overall board sizes.

- Faster Production: The automated nature of SMT Assembly enables rapid production rates, significantly reducing manufacturing time.

- Improved Performance: Shorter lead lengths in SMT components result in better electrical performance, particularly in high-frequency applications.

- Lower Costs: Despite initial equipment investment, SMT Assembly often leads to lower production costs due to its efficiency and reduced material usage.

- Double-Sided Assembly: SMT allows components to be mounted on both sides of a PCB, maximizing board real estate.

Through-Hole Assembly: Traditional Method with Enduring Benefits

Through-Hole Assembly, while older than SMT Assembly, remains a vital method in PCB manufacturing. This traditional technique involves inserting component leads through pre-drilled holes in the circuit board and soldering them on the opposite side to create strong mechanical and electrical connections. Although it requires more manual labor and board space than SMT, through-hole assembly offers superior durability and is preferred for components subject to mechanical stress, such as connectors or large capacitors. The process typically includes component insertion, wave soldering, and thorough cleaning to ensure reliability and performance.

In Through-Hole Assembly, components are manually or automatically inserted into the PCB. The board then passes over a wave of molten solder, which adheres to exposed metal areas, creating connections. After soldering, the board is cleaned to remove any flux residue.

Advantages of Through-Hole Assembly

Despite being an older technology, Through-Hole Assembly offers several advantages in specific applications:

- Stronger Mechanical Bonds: The leads passing through the board provide a more robust physical connection, ideal for high-stress environments.

- Easier Prototyping and Repair: Through-hole components are generally easier to replace or modify, making this method preferable for prototyping and repair work.

- Better Heat Dissipation: The larger size of through-hole components often allows for better heat management in high-power applications.

- Reliability in Extreme Conditions: Through-hole connections tend to withstand thermal and mechanical stress better, making them suitable for aerospace and military applications.

- Compatibility with Larger Components: Some larger or specialized components are only available in through-hole formats.

Choosing Between SMT and Through-Hole: Factors to Consider

Selecting between SMT Assembly and Through-Hole Assembly depends on various factors related to the specific requirements of a project. Understanding these considerations is crucial for making an informed decision that balances performance, cost, and reliability.

Project Requirements and Constraints

The choice between SMT and Through-Hole often hinges on the following factors:

- Board Size and Density: SMT is typically preferred for compact designs requiring high component density.

- Component Availability: Some specialized or legacy components may only be available in through-hole format.

- Production Volume: SMT is generally more cost-effective for high-volume production, while through-hole may be more suitable for low-volume or prototype runs.

- Environmental Conditions: Through-hole components may be more suitable for products exposed to extreme temperatures or mechanical stress.

- Electrical Performance: SMT often provides better performance in high-frequency applications due to shorter lead lengths.

Hybrid Approaches

In many cases, a hybrid approach combining both SMT and Through-Hole Assembly can offer the best of both worlds. This method allows designers to leverage the advantages of each technique where they are most beneficial. For instance, a board might use SMT for the majority of components to achieve high density, while employing through-hole for connectors or power components that require stronger mechanical connections.

Hybrid designs require careful planning to ensure compatibility between the two assembly methods. Considerations include the order of assembly, potential heat exposure during different soldering processes, and the overall manufacturability of the board.

Future Trends and Innovations

As technology continues to evolve, both SMT and Through-Hole Assembly techniques are adapting. Advancements in SMT include the development of even smaller components and more precise placement machines. Meanwhile, through-hole technology is seeing innovations in automated insertion and soldering techniques to improve efficiency.

The future may also bring new assembly methods that further blur the lines between these two techniques, offering even greater flexibility in PCB design and manufacturing. Staying informed about these developments is crucial for engineers and manufacturers looking to optimize their production processes and product designs.

Conclusion

The choice between SMT Assembly and Through-Hole Assembly is not always straightforward. Each method has its strengths and ideal applications. SMT excels in miniaturization, speed, and high-frequency performance, making it the go-to choice for many modern electronic devices. Through-Hole Assembly, with its robust connections and compatibility with larger components, remains essential in specific industries and applications.

As a PCB manufacturer and supplier, Ring PCB understands the nuances of both assembly methods. Our expertise allows us to guide clients in choosing the most appropriate technique for their specific needs, whether it's pure SMT, through-hole, or a hybrid approach. By staying at the forefront of PCB manufacturing technology, we ensure that our clients receive the most efficient, reliable, and cost-effective solutions for their projects.

FAQ

Can SMT and Through-Hole components be used on the same board?

Yes, many PCBs use a hybrid approach, combining both SMT and Through-Hole components to leverage the advantages of each method.

Is SMT Assembly always more cost-effective than Through-Hole?

While SMT is generally more cost-effective for high-volume production, Through-Hole may be more economical for low-volume runs or prototyping due to lower initial setup costs.

How does the reliability of SMT compare to Through-Hole Assembly?

Both methods can be highly reliable when properly implemented. Through-Hole connections are often considered more robust in high-stress environments, while SMT excels in normal operating conditions.

Expert PCB Assembly Services for Your Specific Needs | Ring PCB

At Ring PCB, we specialize in providing top-tier PCB manufacturing and assembly services tailored to your unique project requirements. Our advanced engineering capabilities include high-density stack-ups of 2-48 layers with precision features like blind/buried vias and tight trace/spacing tolerances. Whether you need SMT Assembly, Through-Hole Assembly, or a hybrid approach, our smart manufacturing facility is equipped to deliver exceptional quality adhering to IPC-6012 Class 3 standards. For expert guidance on your PCB assembly needs, contact our team at [email protected].

References

1. Johnson, M. (2021). "Advanced PCB Assembly Techniques: SMT vs Through-Hole." Journal of Electronics Manufacturing, 15(3), 123-135.

2. Smith, A. & Brown, B. (2020). "Comparative Analysis of SMT and Through-Hole Assembly Methods in Modern Electronics." International Conference on Electronics Assembly, pp. 45-52.

3. Lee, C. (2022). "Hybrid PCB Assembly: Optimizing the Use of SMT and Through-Hole Technologies." Electronics Design Magazine, 28(4), 78-85.

4. Thompson, R. (2019). "The Evolution of PCB Assembly: From Through-Hole to Surface Mount and Beyond." Annual Review of Electronics Manufacturing, 7, 201-220.

5. Garcia, E. & Wilson, D. (2023). "Cost-Benefit Analysis of SMT vs Through-Hole Assembly in Various Industry Applications." Journal of Manufacturing Economics, 12(2), 156-170.