Common PCB Base Materials and Their Properties

FR-4: The Versatile Workhorse

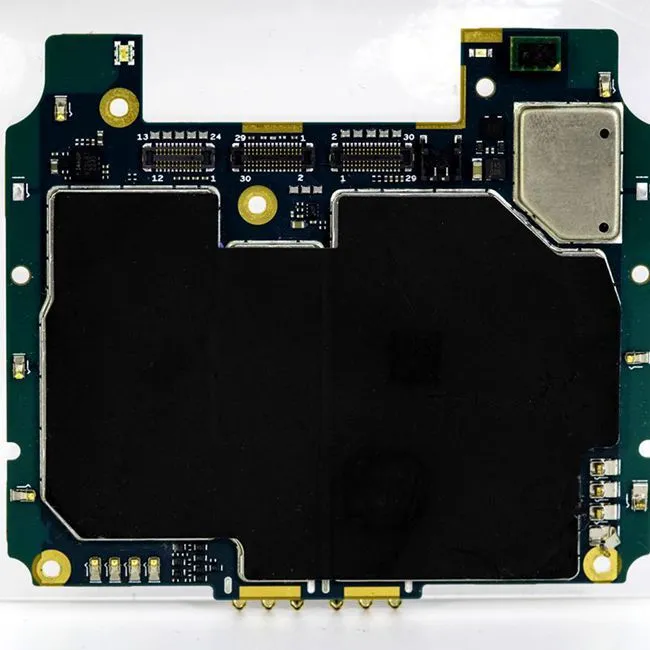

FR-4 (Flame Retardant 4) remains the most widely used PCB material due to its excellent balance of performance and cost-effectiveness. This glass-reinforced epoxy laminate boasts impressive electrical insulation properties and mechanical strength. FR-4 is the go-to choice for many consumer electronics, industrial control systems, and automotive applications. Its versatility allows for complex multilayer designs, making it suitable for high-density interconnect (HDI) boards commonly found in smartphones and tablets.

The thermal stability of FR-4 enables it to withstand the high temperatures of lead-free soldering processes, crucial for assembly operations. However, its relatively high dielectric constant limits its use in high-frequency applications above 1 GHz. Despite this limitation, FR-4 continues to dominate the PCB industry, especially in applications where cost and reliability are paramount.

High-Frequency Laminates: Powering Advanced Communications

As wireless technologies advance, the demand for high-frequency PCB materials has surged. Materials like Rogers 4350B, Taconic RF-35, and Isola Astra MT offer low dielectric constants and low loss tangents, essential for maintaining signal integrity in high-speed digital and RF applications. These laminates are indispensable in 5G infrastructure, satellite communications, and radar systems.

The superior electrical performance of these materials comes at a higher cost compared to FR-4, but the trade-off is necessary for applications requiring precise impedance control and minimal signal loss. Manufacturers often employ these materials in hybrid designs, using them selectively for critical high-frequency sections while utilizing FR-4 for less demanding areas, optimizing both performance and cost.

Flexible and Rigid-Flex PCB Materials: Enabling Design Freedom

Flexible PCB materials, such as polyimide and polyester films, have revolutionized electronic design by allowing circuits to bend, fold, and conform to non-planar surfaces. These materials find extensive use in wearable devices, medical implants, and aerospace applications where space and weight are at a premium. Rigid-flex PCBs, combining flexible and rigid sections, offer the best of both worlds, enabling complex three-dimensional designs that were previously impossible.

The durability of flexible materials under repeated bending cycles makes them ideal for applications like printer heads and automotive dashboards. However, working with these materials requires specialized manufacturing processes and design considerations to ensure reliability. Advanced assembly techniques, including careful handling during SMT processes and specialized testing procedures, are crucial for successful flexible and rigid-flex PCB production.

Specialized PCB Materials for Extreme Conditions

High-Temperature PCB Materials

In applications where standard FR-4 falls short due to extreme heat, specialized high-temperature PCB materials come into play. Polyimide-based laminates and ceramic-filled PTFE composites can withstand continuous operating temperatures above 200°C, making them suitable for automotive engine control units, aerospace avionics, and oil and gas exploration equipment.

These materials not only maintain their electrical and mechanical properties at high temperatures but also resist thermal degradation over time. This resilience is crucial for ensuring the long-term reliability of electronic systems in harsh environments. Manufacturers must employ precise assembly techniques and rigorous testing protocols to guarantee the integrity of high-temperature PCBs under extreme conditions.

Metal-Core PCBs: Thermal Management Solutions

Metal-core PCBs (MCPCBs) address the growing challenge of heat dissipation in high-power electronics. By incorporating a metal base layer, typically aluminum or copper, these PCBs efficiently conduct heat away from components. LED lighting, power supplies, and motor controllers benefit significantly from MCPCBs' superior thermal management capabilities.

The manufacturing process for MCPCBs involves bonding a thin dielectric layer to the metal core, followed by the circuit layer. This construction requires specialized assembly equipment and expertise to handle the unique thermal properties of the material. Advanced testing methods, including thermal cycling and power cycling, are essential to validate the reliability of MCPCBs in demanding applications.

Halogen-Free Materials: Meeting Environmental Standards

As environmental regulations tighten globally, the demand for halogen-free PCB materials has increased. These materials eliminate brominated and chlorinated flame retardants, reducing the environmental impact of electronic waste. Halogen-free laminates offer comparable performance to traditional FR-4 while meeting stringent environmental standards.

The transition to halogen-free materials requires adjustments in manufacturing processes, including careful control of lamination parameters and drilling techniques. Assembly operations must also be optimized to ensure compatibility with these new materials. Rigorous testing for flame retardancy and electrical performance is crucial to verify that halogen-free PCBs meet both regulatory requirements and performance standards.

Future Trends in PCB Materials

Advanced Composites for Next-Generation Electronics

The PCB industry is continuously evolving, with research focusing on novel materials to meet the demands of future technologies. Graphene-based composites show promise for ultra-high-frequency applications, potentially revolutionizing 6G and beyond communications systems. Biodegradable PCB materials are also under development, aiming to address the growing concern of electronic waste.

These emerging materials present new challenges and opportunities for PCB manufacturers. Advanced assembly techniques, such as laser drilling for ultra-fine vias and precision component placement, will be crucial for leveraging the full potential of these materials. Manufacturers investing in cutting-edge testing and quality control measures will be best positioned to adopt these innovative PCB materials as they become commercially viable.

Smart Materials and Embedded Components

The integration of smart materials and embedded components directly into PCB substrates represents a frontier in electronics manufacturing. Materials with self-healing properties or the ability to change characteristics in response to environmental conditions could dramatically enhance the reliability and adaptability of electronic systems. Embedding passive components within the PCB layers offers significant advantages in miniaturization and performance optimization.

Realizing these advanced concepts requires a paradigm shift in PCB manufacturing and assembly processes. Techniques such as 3D printing of conductive and dielectric materials directly onto PCB substrates are being explored. These innovations demand sophisticated testing methodologies to ensure the integrity and functionality of these complex, integrated systems throughout their lifecycle.

Sustainability and Recyclability

As the electronics industry faces increasing pressure to reduce its environmental footprint, the focus on sustainable and recyclable PCB materials is intensifying. Bio-based laminates derived from renewable resources and PCB materials designed for easy disassembly and recycling are areas of active research and development. These initiatives aim to create a more circular economy for electronic products.

Implementing sustainable PCB materials requires holistic changes in the manufacturing ecosystem. From sourcing eco-friendly raw materials to developing new recycling technologies, the entire supply chain must adapt. Advanced assembly techniques that facilitate easy separation of components and materials at end-of-life will be crucial. Comprehensive lifecycle analysis and environmental impact testing will become standard practices in the PCB industry.

Conclusion

The world of PCB materials is vast and ever-evolving, with each type offering unique properties suited to specific applications. From the ubiquitous FR-4 to cutting-edge high-frequency laminates and flexible substrates, the choice of PCB material significantly impacts the performance, reliability, and cost of electronic devices. As technology advances, so too does the demand for more specialized and high-performance PCB materials.

For manufacturers and engineers seeking reliable PCB suppliers and manufacturers, understanding the nuances of different PCB materials is crucial. It enables informed decisions in product design and development, ensuring optimal performance and cost-effectiveness. The future of PCB materials promises even more innovation, with smart materials, embedded components, and sustainable options on the horizon, further expanding the possibilities in electronic design and manufacturing.

FAQ

What factors should I consider when choosing PCB materials for my project?

Consider factors such as operating frequency, thermal requirements, mechanical stress, environmental conditions, and cost constraints.

Are there eco-friendly options for PCB materials?

Yes, halogen-free and bio-based PCB materials are becoming more prevalent. These options offer similar performance to traditional materials while reducing environmental impact.

How do flexible PCB materials differ from rigid ones in terms of manufacturing and assembly?

Flexible PCBs require specialized handling during manufacturing and assembly due to their bendable nature. They often use different adhesives and require careful attention to bend radii and flexing zones during design and production.

Expert PCB Manufacturing and Assembly Services | Ring PCB

At Ring PCB, we specialize in advanced PCB manufacturing and assembly, offering comprehensive solutions for complex multilayer and HDI designs. Our state-of-the-art facility ensures precision in every aspect of PCB production, from high-density stack-ups to rigorous quality control measures. With our expertise in handling diverse PCB materials and advanced assembly techniques, we deliver reliable, high-performance PCBs tailored to your specific project requirements. For expert PCB manufacturing and assembly services, contact us at [email protected].

References

1. Rogers Corporation. (2022). High Frequency PCB Materials: Properties and Applications.

2. Isola Group. (2021). PCB Laminate Materials for High-Speed Digital and RF Applications. Isola Technical Library.

3. IPC — Association Connecting Electronics Industries. (2020). IPC-4101C: Specification for Base Materials for Rigid and Multilayer Printed Boards. IPC International, Inc.

4. Taconic Advanced Dielectric Division. (2023). High-Frequency Laminates: Design Considerations and Performance Data. Taconic Technical Paper Series.

5. Lee, S. H., & Kim, J. Y. (2022). Sustainable and High-Performance PCB Materials: Trends and Future Perspectives. Journal of Electronic Materials, 51(9), 4823–4838.