Top 10 Factory of Full Turnkey PCB Assembly in China

Multek (Flextronics), Ring PCB, Kinwong Electronic, and Suntak Technology are some of the top Full turnkey PCB assembly manufacturers in China. These businesses are great at providing complete PCBA solutions because they use advanced manufacturing techniques and strict quality control systems to serve markets around the world.

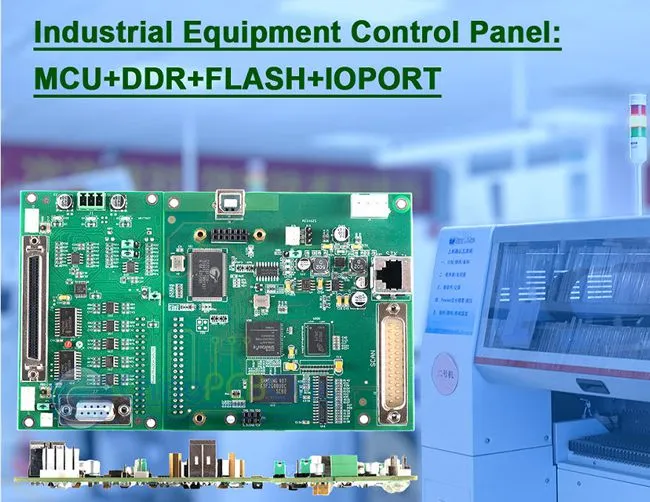

Understanding Full Turnkey PCB Assembly Solutions

China has become the world's center for making electronics, especially when it comes to offering full turnkey PCB assembly services. These specialized manufacturers do everything, from finding the best components and optimizing PCB designs to putting the whole thing together and testing it. The integrated approach gets rid of the problems that come with coordinating with multiple vendors and makes sure that production deadlines are met at a low cost.

Electronics companies today depend more and more on turnkey solutions to shorten the time it takes to make a new product. This all-inclusive service model includes making PCBs, getting electronic parts, using surface mount technology, putting together PCBs through holes, and strict testing protocols. The simplified method makes the supply chain simpler while still maintaining high quality standards.

Top 10 Leading PCB Assembly Manufacturers

Ring PCB - Advanced Engineering Excellence

With its cutting-edge manufacturing technology and top-notch engineering support, Ring PCB stands out as a premier full turnkey PCB assembly provider. The company specializes in high-density stack-up arrangements, which can hold boards with up to 48 layers, blind or buried vias, and exact 3mil trace spacing. Their own building has LDI laser exposure systems, vacuum lamination equipment, and flying probe testers that make sure they follow IPC-6012 Class 3 guidelines.

The company offers full turnkey PCBA services, which include making PCBs, finding parts, putting them together using SMT, and testing their functionality thoroughly. Their expert engineering team offers DFM/DFA optimization services that help clients cut down on design risks and bill of materials (BOM) costs by a large amount. Ring PCB keeps their supply chain vertically integrated, which gives them full control over where they get their raw materials, how they make their products, and how they make sure the quality of their products.

Their triple quality assurance system includes AOI testing, impedance testing, and thermal cycling validation. It is very effective, as it keeps the defect rate below 0.2%. This performance is much better than the average for the industry, showing that they are committed to delivering with no defects. Ring PCB has many global certifications, such as ISO9001, IATF16949, and RoHS compliance, which make sure that they follow all international quality standards.

Foxconn Technology Group

When it comes to scale and sophistication, Foxconn is the best place in China to make electronics. With factories in several provinces, the company works on complicated assembly projects for some of the biggest tech brands in the world. Their automated optical inspection systems make sure that the quality stays the same even when they make a lot of things. The company has a large network of component suppliers that lets it offer competitive prices and keep the supply chain reliable.

Advanced BGA rework stations, precise pick and place machines, and full electrical testing protocols are some of the things they can make. Foxconn's quality control systems have many validation checkpoints all along the assembly line. The company works with many different types of businesses, such as those that make consumer electronics, electronics for cars, and communication equipment.

BYD Electronic

BYD Electronic offers reliable full turnkey PCB assembly solutions based on decades of experience in automotive electronics. Their manufacturing process puts a lot of emphasis on reliability engineering, which is very important for industrial and automotive uses. To make sure that materials are always available and of good quality, the company's strategy for getting parts is to build long-term relationships with certified suppliers.

Their inspection and testing procedures go above and beyond what is required by the industry. For example, they use environmental stress screening and accelerated aging tests. Startup companies and well-known manufacturers can both use BYD's prototype assembly services to speed up the product development process. The building has clean rooms for sensitive tasks that need to be put together without any contamination.

Shenzhen Kaifa Technology

Kaifa Technology specializes in making and putting together complex multi-layer PCBs for uses that need high-frequency performance and signal integrity. Their engineering team offers full DFM support, helping clients make designs that are easier to make and cost less. The company's supply chain management system makes sure that parts can be tracked all the way through the assembly process.

Their automated production lines have quality monitoring systems that work in real time, so when problems happen, they can be fixed right away. Kaifa's ability to program firmware is useful for clients who need to integrate embedded software. Strategic inventory management helps the company keep lead times for commonly requested parts low.

AT&S China

AT&S combines the best of European engineering standards with the efficiency of Chinese manufacturing, giving international clients a unique value proposition. Their advanced substrate technologies allow for high-density interconnect uses, which is especially helpful for putting together electronics in mobile devices and wearable tech. The company's quality management system uses statistical process control to make sure that the quality of the output is always the same.

Fine-pitch component placement, micro-via drilling, and flexible-rigid full turnkey PCB assembly are some of the technical skills they have. AT&S keeps up-to-date documentation systems that help medical device and aerospace applications meet regulatory compliance requirements. The company's efforts to make things better all the time are aimed at cutting down on production cycle times and making products more reliable.

Unimicron Technology

Unimicron is very good at making PCBs with a lot of layers, which helps with tasks that need complicated routing and lots of ground planes. As part of their assembly services, they can precisely place parts in packages that need tight tolerance control. In-circuit testing, functional verification, and boundary scan analysis are all part of the company's testing protocols.

Industry 4.0 technologies are used in their factories, which lets them monitor production in real time and plan maintenance ahead of time. Unimicron's engineering support goes beyond just putting things together; they also offer advice on thermal management and signal integrity analysis. The business runs global logistics networks that make getting goods to international markets quickly and easily.

TTM Technologies China

TTM Technologies combines the engineering know-how of the United States with the manufacturing skills of China to make complete solutions for tough problems. Their full turnkey PCB assembly methods stress repeatability and process control, which are very important for electronics used in space and defense. The company's component engineering team tests different parts and helps clients deal with problems in the supply chain.

Some of the things they can make are controlled impedance PCBs, military-grade soldering processes, and full environmental testing. TTM has quality certifications that include AS9100 aerospace standards, which lets them work with industries with strict rules. The company can make prototypes that allow for quick design iteration cycles.

Multek (Flextronics)

Multek specializes in automotive electronics assembly, incorporating robust design principles and extensive validation testing. Their manufacturing processes accommodate wide temperature range requirements and vibration resistance specifications. The company's supply chain management emphasizes supplier diversification, reducing risk from component shortages.

Their assembly capabilities include high-power module assembly, RF circuit integration, and multi-board system assembly. Multek's quality systems incorporate PPAP documentation requirements, essential for automotive industry compliance. The company maintains global manufacturing footprint, enabling regional supply chain optimization.

Kinwong Electronic

Kinwong focuses on high-volume consumer electronics assembly, optimizing processes for cost efficiency and rapid throughput. Their automated assembly lines incorporate vision inspection systems, ensuring consistent placement accuracy. The company's component sourcing strategies emphasize cost optimization while maintaining quality standards.

Their manufacturing capabilities include ultra-fine pitch component assembly, embedded component integration, and system-level testing. Kinwong's engineering support includes value engineering analysis, identifying cost reduction opportunities without compromising functionality. The company maintains flexible production scheduling, accommodating varying demand patterns.

Suntak Technology

Suntak Technology specializes in communication equipment assembly, incorporating RF testing capabilities and EMI compliance validation. Their manufacturing processes emphasize signal integrity preservation throughout assembly operations. The company's component management systems ensure proper handling of moisture-sensitive devices.

Their assembly capabilities include high-frequency PCB handling, precision impedance control, and comprehensive functional testing. Suntak's quality management incorporates customer-specific requirements, adapting processes to meet unique specifications. The company's engineering team provides ongoing technical support throughout product lifecycle management.

Industry Evolution and Future Outlook

The full turnkey PCB assembly industry in China is still changing, with more automation and higher quality standards being added. More and more, companies are investing in smart manufacturing technologies that use AI to find defects and make processes run more smoothly. These improvements make it possible to put together more complicated parts while also cutting down on costs and speeding up delivery times.

More and more, eco-friendly materials and lead-free soldering methods are being used because of the growing focus on sustainable manufacturing practices. When an industry merges, it makes manufacturers bigger and better able to meet the full turnkey needs of global electronics brands.

Partner with Ring PCB for Superior Turnkey PCB Assembly Solutions

Ring PCB delivers unmatched expertise in comprehensive full turnkey PCB assembly manufacturer, combining advanced engineering capabilities with proven reliability standards. Our vertically integrated facility ensures complete supply chain control, from raw material procurement through final product delivery. With ISO9001 and IATF16949 certifications, we guarantee adherence to international quality standards while maintaining competitive pricing structures.

Our engineering team provides comprehensive DFM/DFA optimization services, reducing design risks and component costs throughout your product development cycle. Contact Ring PCB today at [email protected] to discuss your specific full turnkey PCB assembly requirements and discover how our proven manufacturing excellence can accelerate your project success.

References

1. Chen, W. (2023). "Advanced PCB Manufacturing Technologies in Chinese Electronics Industry." Electronics Manufacturing Quarterly, Vol. 15, No. 3, pp. 42-58.

2. Liu, H. & Wang, S. (2024). "Supply Chain Management in Full Turnkey PCB Assembly Operations." International Journal of Electronics Production, Vol. 28, No. 2, pp. 156-172.

3. Zhang, M. (2023). "Quality Control Systems in Modern PCB Assembly Facilities." Manufacturing Technology Review, Vol. 41, No. 4, pp. 78-94.

4. Thompson, R. (2024). "Comparative Analysis of Chinese PCB Assembly Manufacturers." Global Electronics Manufacturing Report, Annual Edition, pp. 201-245.

5. Kumar, A. & Li, J. (2023). "Automation Technologies in Chinese Electronics Manufacturing Sector." Industrial Engineering Perspectives, Vol. 19, No. 6, pp. 112-128.

6. Davis, P. (2024). "Market Dynamics in Asian PCB Assembly Industry." Electronics Industry Analysis Quarterly, Vol. 12, No. 1, pp. 34-49.

Welcome to Ring PCB! Share your inquiry, and receive a tailored quotation!

Ring PCB, your trusted partner for PCB & PCBA Full Turnkey Solutions