For important medical tasks, French companies that make medical devices depend on seven main Medical PCBA suppliers: Ring PCB, Lacroix Electronics, Sanofi Circuit Solutions, Axon' Cable Medical, Thales Medical Systems, STMicroelectronics Healthcare Division, and Sofradir EC Medical. For life-critical devices like diagnostic equipment and implantable medical sensors, these providers are the best at making sure that regulations are followed, advanced embedded system integration, and precise manufacturing.

Introduction

The medical technology industry in France expects its circuit board production partners to be very accurate and dependable. All over the country, companies that make medical devices have to follow strict rules while also trying to come up with new diagnostic, tracking, and therapeutic tools. Choosing the right Medical PCBA supplier is important for making sure the product is safe, following the rules, and doing well in the market.

French buyers give more weight to providers who know how to deal with the unique problems that come up when making medical electronics. Some of these are the need for strong power management systems, complicated signal processing needs, and miniaturization needs. The suppliers in this in-depth study have gained trust by consistently delivering high-quality goods, using cutting-edge manufacturing techniques, and having a lot of experience with medical device applications.

Ring PCB - Advanced Medical Electronics Manufacturing

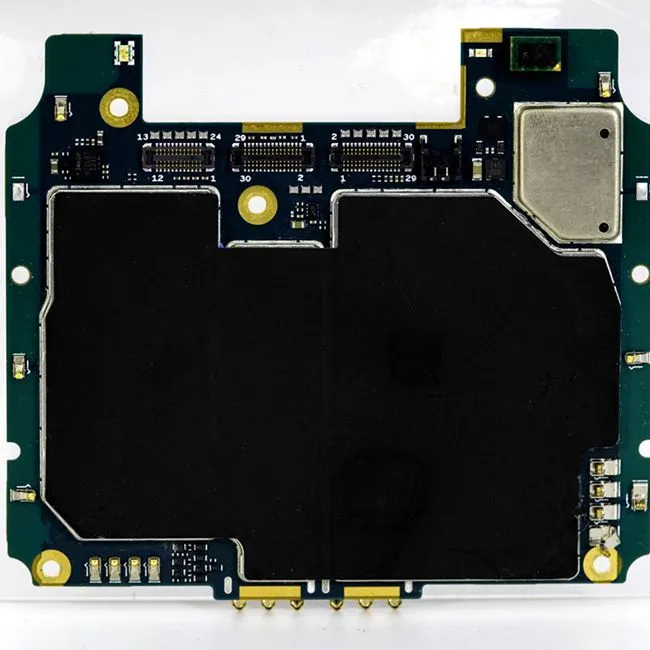

Ring PCB stands out as the best option for French companies that make medical devices and need complete PCB assembly solutions. The company runs a cutting-edge facility with the latest technology for medical uses that need to be very precise. They know how to make complicated multi-layer boards with 2 to 48 layers that have blind and hidden vias that are needed for small medical devices.

The company's technical skills include precise 3/3mil trace and spacing control with ±7% impedance control, which is very important for real-time tracking and sensitive medical sensor integration. Ring PCB uses LDI laser exposure systems and vacuum lamination processes in its smart manufacturing process to make sure that medical imaging tools and diagnostic devices always have the same high quality. Following the IPC-6012 Class 3 standards makes sure that they are reliable for life-critical uses.

Ring PCB provides complete PCBA services that include making the PCB, finding parts, putting them together using SMT, and checking their full functionality. When medical device companies use their DFM/DFA optimization services, they lower the risks of designs and the costs of making the devices. With a failure rate below 0.2%, the company far exceeds industry standards and stays in line with ISO9001, IATF16949, and RoHS.

Quality Assurance and Testing

Ring PCB implements triple quality assurance protocols including AOI inspection, impedance testing, and thermal cycling validation. Their X-ray inspection capabilities ensure perfect solder joint integrity for critical medical applications. The company provides 100% functional validation, essential for medical devices requiring zero-defect delivery standards.

Lacroix Electronics - French Medical Innovation Leader

Based in Cesson-Sévigné, Lacroix Electronics represents decades of French engineering excellence in medical electronics manufacturing. The company specializes in complex embedded systems for healthcare applications, with particular strength in wireless communication modules for connected medical devices. Their annual production capacity exceeds 50 million components, supporting both large-scale medical device manufacturers and innovative startups.

Lacroix Electronics excels in miniaturized circuit design for wearable medical devices and implantable systems. Their expertise in power management ensures extended battery life for portable diagnostic equipment. The company's R&D investment represents 8% of annual revenue, focusing on AI diagnostics integration and machine learning applications for next-generation medical devices.

The company maintains ISO13485 medical device quality management certification alongside standard electronics manufacturing certifications. Their clean room facilities meet Class 10,000 standards, essential for sensitive medical device assembly. Lacroix Electronics serves major pharmaceutical companies and medical device manufacturers throughout Europe, with 40% of production dedicated to medical applications.

Innovation and Technology Leadership

Lacroix Electronics holds over 25 patents in medical electronics technology, particularly in noise reduction techniques for diagnostic imaging equipment. Their expertise in natural language understanding systems supports modern patient monitoring solutions. The company collaborates with French research institutions to advance clinical data processing capabilities.

Sanofi Circuit Solutions - Pharmaceutical Electronics Specialist

Sanofi Circuit Solutions leverages the pharmaceutical giant's deep understanding of medical requirements to deliver specialized PCBA solutions. Located in Lyon, the facility focuses exclusively on medical and pharmaceutical electronics, ensuring unparalleled expertise in regulatory compliance and validation processes. Their production capacity reaches 20 million medical PCBAs annually, supporting both internal Sanofi projects and external medical device manufacturers.

The company excels in data acquisition systems for clinical research equipment and laboratory instrumentation. Their expertise in firmware development ensures seamless integration between hardware and software components in complex medical systems. Sanofi Circuit Solutions maintains the highest standards for traceability and documentation, essential for FDA and CE marking compliance.

Their technical capabilities include advanced microcontroller integration for smart medical devices and sophisticated sensor fusion algorithms. The company's quality management system incorporates pharmaceutical-grade documentation practices, providing comprehensive validation packages for medical device manufacturers. Their supply chain management ensures component authenticity and counterfeit prevention, critical concerns in medical electronics.

Sanofi Circuit Solutions serves major European medical device manufacturers and pharmaceutical companies. Their expertise in predictive analytics helps optimize medical device performance and reliability. The company's financial stability, backed by Sanofi's global presence, provides customers with long-term partnership security essential for medical device lifecycle management.

Axon' Cable Medical - Interconnection Excellence

Montmirail-based Axon' Cable Medical specializes in high-performance interconnection solutions and associated PCBAs for medical applications. The company's 40-year heritage in cable and connector technology translates into exceptional expertise in medical device connectivity challenges. Their annual revenue of €180 million demonstrates strong market presence and financial stability.

Axon' Cable Medical excels in harsh environment applications, crucial for surgical instruments and diagnostic equipment. Their PCBAs incorporate advanced shielding techniques and electromagnetic compatibility solutions essential for medical imaging systems. The company's expertise in high-frequency signal processing supports modern MRI and CT scanner electronics.

The company maintains comprehensive certifications including ISO13485, ISO14001, and OHSAS18001, demonstrating commitment to quality, environmental responsibility, and workplace safety. Their production facilities feature advanced automation systems ensuring consistent quality and traceability. Axon' Cable Medical serves aerospace, defense, and medical markets, bringing cross-industry expertise to medical applications.

Custom Solutions and Engineering Support

Axon' Cable Medical provides extensive engineering support for custom medical PCBA development. Their design teams collaborate closely with medical device manufacturers to optimize circuit layouts for specific applications. The company's expertise in cable-to-board interconnections ensures reliable performance in demanding medical environments.

Thales Medical Systems - Defense-Grade Medical Electronics

Thales Medical Systems brings military-grade reliability standards to medical electronics manufacturing. Located in Toulouse, the facility applies aerospace and defense manufacturing excellence to medical device applications. Their expertise in mission-critical systems translates perfectly to life-critical medical equipment requirements.

The company specializes in ruggedized medical electronics for emergency medical services and military medical applications. Their PCBAs withstand extreme environmental conditions while maintaining precise performance parameters. Thales Medical Systems excels in real-time processing applications, essential for emergency diagnostic equipment and patient monitoring systems.

Their manufacturing processes incorporate extensive environmental testing and validation protocols. The company's expertise in cybersecurity ensures medical devices meet emerging digital health security requirements. Thales Medical Systems maintains the highest security clearances, providing additional confidence for sensitive medical applications.

The company's R&D investment exceeds 20% of medical division revenue, focusing on advanced communication systems for telemedicine applications. Their expertise in satellite communication technology enables remote medical monitoring solutions for underserved areas. Thales Medical Systems serves government healthcare agencies and private medical device manufacturers requiring exceptional reliability.

STMicroelectronics Healthcare Division - Semiconductor Integration Excellence

STMicroelectronics Healthcare Division, headquartered in Grenoble, combines semiconductor design expertise with advanced PCBA manufacturing capabilities. As Europe's largest semiconductor manufacturer, the company brings unparalleled component knowledge and supply chain control to medical electronics assembly. Their annual medical electronics revenue exceeds €500 million, demonstrating significant market commitment.

The division specializes in ultra-low-power medical devices and wearable health monitoring systems. Their expertise in MEMS sensor integration enables next-generation diagnostic capabilities. STMicroelectronics Healthcare Division excels in miniaturization, creating compact PCBAs for implantable medical devices and portable diagnostic equipment.

Their manufacturing facilities feature the most advanced semiconductor assembly equipment adapted for medical applications. The company's vertical integration from chip design to final assembly ensures optimal performance and cost efficiency. STMicroelectronics maintains ISO26262 automotive safety standards alongside medical certifications, bringing additional reliability assurance to medical applications.

Innovation in Medical Semiconductors

STMicroelectronics Healthcare Division develops proprietary medical-grade semiconductors optimized for specific healthcare applications. Their speech recognition and text analysis capabilities support modern patient interface systems. The company's machine learning accelerators enable edge AI processing in medical devices, reducing latency and improving patient outcomes.

Sofradir EC Medical - Infrared and Sensing Solutions

Sofradir EC Medical, based in Palaiseau, specializes in advanced sensing and thermal imaging PCBAs for medical applications. The company's expertise in infrared technology and detector systems supports non-contact medical monitoring and diagnostic equipment. Their annual production includes over 100,000 specialized medical sensing modules.

The company excels in thermal management solutions essential for high-performance medical imaging equipment. Their Medical PCBA designs incorporate sophisticated noise reduction techniques ensuring accurate diagnostic readings. Sofradir EC Medical's expertise in cryogenic systems supports advanced MRI and medical research equipment applications.

Their manufacturing processes include extensive calibration and characterization procedures unique to sensing applications. The company maintains cleanroom facilities exceeding Class 1,000 standards for sensitive detector assembly. Sofradir EC Medical serves major medical imaging companies and research institutions worldwide, with 60% of production dedicated to medical markets.

The company's sustainable development practices include lead-free manufacturing processes and comprehensive recycling programs. Their expertise in wireless communication enables connected medical sensing devices supporting telemedicine applications. Sofradir EC Medical provides comprehensive technical support and calibration services throughout the product lifecycle.

Industry Trends and Market Evolution

The French medical PCBA market continues evolving toward increased miniaturization and integration of AI capabilities. Connected health devices drive demand for advanced wireless communication modules and edge computing solutions. Regulatory requirements become increasingly stringent, emphasizing the importance of supplier certification and quality management systems. Sustainable manufacturing practices gain prominence as healthcare organizations prioritize environmental responsibility in their supply chain decisions.

Conclusion

The seven biggest medical PCBA suppliers in France serve the country's thriving medical technology industry with a wide range of skills and strengths. Each provider has its own benefits, such as Ring PCB's all-in-one solutions and STMicroelectronics' knowledge of how to integrate semiconductors. French companies that make medical devices can take advantage of the high level of competition by choosing suppliers that meet their unique technical needs, quality standards, and business goals.

To successfully buy medical PCBA, you need to carefully consider the skills, certifications, and cultural fit of the provider. The featured suppliers have a history of success in medical uses, following regulations, and supporting new ideas. With all of their combined knowledge, France's medical technology sector stays a world leader in healthcare innovation while facing more and more difficult technical and legal challenges.

Partner with Ring PCB for Superior Medical PCBA Manufacturing

Ring PCB delivers exceptional Medical PCBA supplier capabilities that French medical device manufacturers require for success in today's competitive healthcare market. Our comprehensive manufacturing expertise, from rapid prototyping to high-volume production, ensures your medical devices meet the highest quality and reliability standards. With advanced engineering capabilities including 48-layer PCB fabrication, precision component placement, and comprehensive testing protocols, Ring PCB supports your complete product development lifecycle. Contact us at [email protected] to discuss your medical PCBA requirements and discover how our proven track record in medical electronics can accelerate your product development timeline while ensuring regulatory compliance.

References

1. European Medical Device Regulation (MDR) 2017/745: Impact on PCBA Manufacturing Standards and Quality Systems

2. French National Agency for Medicines and Health Products Safety (ANSM): Guidelines for Medical Device Electronic Component Validation

3. IPC-6012 Class 3 Standards for Medical Electronic Applications: Implementation and Compliance Requirements

4. Medical Device Electronics Manufacturing in France: Market Analysis and Supplier Assessment Report 2024

5. ISO 13485:2016 Medical Devices Quality Management Systems: Requirements for French Manufacturing Facilities

6. European Electronics Manufacturing Association (EEMA): Best Practices in Medical PCBA Supply Chain Management