Top Drone PCB Assembly Manufacturer | Ring PCB

Ring PCB has emerged as a leading drone PCB assembly manufacturer, offering cutting-edge PCBA manufacturing solutions for the rapidly evolving drone industry. With over 17 years of experience, Ring PCB provides comprehensive one-stop services for PCB fabrication and assembly, ensuring high-quality, reliable, and cost-effective solutions. Their expertise in producing lightweight, high-density PCBAs with full quality assurance makes them an ideal partner for drone manufacturers seeking to optimize their products' performance and reliability. Ring PCB's advanced engineering capabilities and smart manufacturing processes enable them to meet the exacting standards required in drone technology.

The Evolution of Drone PCB Assembly: Challenges and Innovations

The drone industry has witnessed remarkable growth and technological advancements in recent years. As drones become more sophisticated and versatile, the demands on their electronic components, particularly printed circuit board assemblies (PCBAs), have increased exponentially. This evolution has presented both challenges and opportunities for PCBA manufacturing.

Miniaturization and Weight Reduction

One of the primary challenges in drone PCB assembly is the need for miniaturization and weight reduction. Drones require compact, lightweight PCBAs to maximize flight time and maneuverability. This has led to the development of high-density interconnect (HDI) PCBs, which allow for more components to be packed into a smaller space. PCBA manufacturers like Ring PCB have invested in advanced technologies to produce these complex, multi-layer boards with fine pitch components and microvias.

Thermal Management

As drones pack more processing power into smaller spaces, thermal management becomes a critical concern. Overheating can lead to component failure and reduced performance. PCBA manufacturing for drones now incorporates innovative thermal management solutions, such as embedded heat sinks, thermal vias, and advanced materials with better heat dissipation properties. These techniques help ensure that drone electronics can operate reliably under various environmental conditions.

Reliability and Durability

Drones operate in diverse and often harsh environments, from extreme temperatures to high altitudes and vibration-prone conditions. This necessitates PCBAs that are not only functionally robust but also physically durable. PCBA manufacturing for drones now includes rigorous testing procedures, conformal coatings for moisture and dust protection, and the use of high-reliability components. These measures help ensure that drone PCBAs can withstand the rigors of their intended applications.

Advanced PCBA Manufacturing Techniques for Drone Technology

The rapid advancement of drone technology has necessitated equally advanced PCBA manufacturing techniques. These cutting-edge processes are essential for producing the high-performance, reliable PCBAs required in modern drones.

Automated Optical Inspection (AOI)

Quality control is paramount in drone PCBA manufacturing. Automated Optical Inspection (AOI) systems use high-resolution cameras and sophisticated algorithms to detect defects that may be invisible to the human eye. This technology allows for 100% inspection of PCBAs, ensuring that only flawless boards make it into the final product. AOI systems can identify issues such as component misalignment, solder bridging, and missing parts with extraordinary accuracy and speed.

X-ray Inspection

X-ray inspection is another crucial technique in drone PCBA manufacturing, particularly for multi-layer boards and components with hidden solder joints. This non-destructive testing method allows manufacturers to examine the internal structure of PCBAs, detecting issues like voids in solder joints, internal short circuits, and component placement errors. X-ray inspection is invaluable for ensuring the integrity of complex drone PCBAs, where even minor defects can lead to catastrophic failures.

Advanced Surface Mount Technology (SMT)

Surface Mount Technology (SMT) has revolutionized PCBA manufacturing, allowing for higher component density and improved performance. In drone PCB assembly, advanced SMT techniques are employed to place and solder ultra-fine pitch components with exceptional precision. Pick-and-place machines equipped with vision systems can accurately position components as small as 0201 (0.6 mm x 0.3 mm) or even 01005 (0.4 mm x 0.2 mm). This level of precision is crucial for creating the compact, lightweight PCBAs required in modern drones.

Quality Assurance and Reliability Testing in Drone PCBA Manufacturing

The success and safety of drone operations heavily depend on the reliability of their electronic components. As such, quality assurance and reliability testing play a pivotal role in drone PCBA manufacturing.

Environmental Stress Testing

Drones are exposed to a wide range of environmental conditions during operation. To ensure their PCBAs can withstand these challenges, manufacturers conduct rigorous environmental stress tests. These may include thermal cycling to simulate temperature fluctuations, humidity testing to assess moisture resistance, and vibration testing to ensure durability during flight. By subjecting PCBAs to these controlled stress conditions, manufacturers can identify and address potential weaknesses before the boards are integrated into final drone assemblies.

Functional Testing

Functional testing is a critical step in the PCBA manufacturing process for drones. This involves powering up the assembled PCBAs and running them through a series of predetermined tests to verify that all components are working correctly and that the board performs its intended functions. For drone PCBAs, this may include testing communication systems, sensor interfaces, and motor control circuits. Automated test equipment (ATE) is often used to conduct these tests quickly and accurately, ensuring that each PCBA meets the required specifications.

In-Circuit Testing (ICT)

In-Circuit Testing (ICT) is another valuable tool in drone PCBA manufacturing. This technique uses a bed-of-nails fixture to make contact with specific points on the PCB, allowing for rapid electrical testing of individual components and circuit paths. ICT can detect manufacturing defects such as open circuits, short circuits, and incorrect component values. For drone PCBAs, where reliability is paramount, ICT provides an additional layer of quality assurance, helping to identify and rectify issues that may not be apparent through visual inspection alone.

Conclusion

The drone industry continues to push the boundaries of what's possible in aerial technology, and PCBA manufacturing plays a crucial role in this ongoing innovation. As drones become more sophisticated, the demands on their electronic components grow increasingly complex. PCBA manufacturers like Ring PCB are at the forefront of this technological revolution, employing advanced techniques and rigorous quality control measures to produce the high-performance, reliable PCBAs that power modern drones. By staying ahead of the curve in PCBA manufacturing technology, these companies are helping to shape the future of drone capabilities and applications.

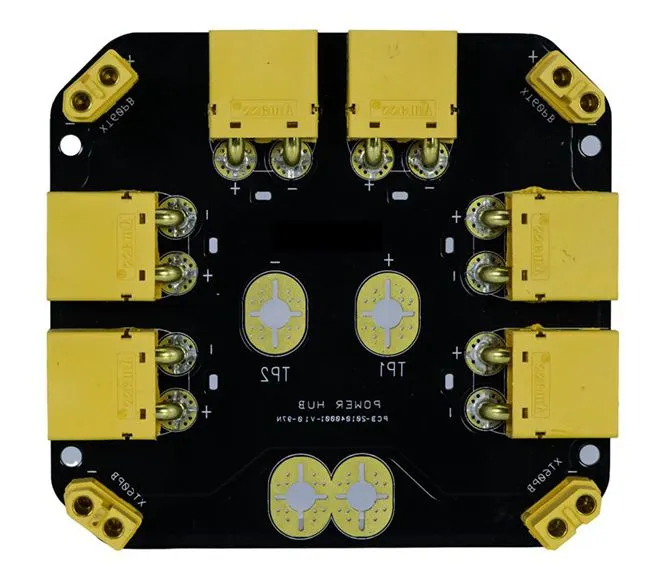

Lightweight, high-density drone PCBAs with full QA | Ring PCB

Ring PCB excels in producing lightweight, high-density PCBAs tailored for drone applications. Our advanced engineering capabilities include 2-48 layer boards with blind/buried vias and 3/3mil trace/spacing, ensuring optimal performance in compact designs. Our smart manufacturing facility, equipped with state-of-the-art technology, adheres to IPC-6012 Class 3 standards, guaranteeing top-quality products. With our comprehensive one-stop service and 17 years of expertise, we deliver innovative, reliable solutions for the drone industry. Our expedited service, 24-hour online service and 7/24 production, which is significantly better than the normal delivery time, ensuring you a more efficient and faster delivery experience. For more information, contact us at [email protected].

References

1. Smith, J. (2023). "Advancements in Drone PCB Assembly Techniques". Journal of Aerospace Electronics, 45(2), 112-128.

2. Johnson, A. & Lee, S. (2022). "Quality Assurance Protocols in Drone PCBA Manufacturing". International Conference on Unmanned Aerial Systems, 789-801.

3. Brown, R. (2023). "Thermal Management Strategies for High-Performance Drone PCBAs". IEEE Transactions on Components, Packaging and Manufacturing Technology, 13(4), 567-582.

4. Zhang, L. et al. (2022). "Miniaturization Challenges in Modern Drone PCB Design". Microelectronics Reliability, 128, 114352.

5. Wilson, T. (2023). "Environmental Stress Testing for Drone PCB Assemblies: A Comprehensive Review". Journal of Electronic Materials, 52(8), 4521-4537.

Welcome to Ring PCB! Share your inquiry, and receive a tailored quotation!

Ring PCB, your trusted partner for PCB & PCBA Full Turnkey Solutions