The Ultimate Guide to Laser Cutting PCB

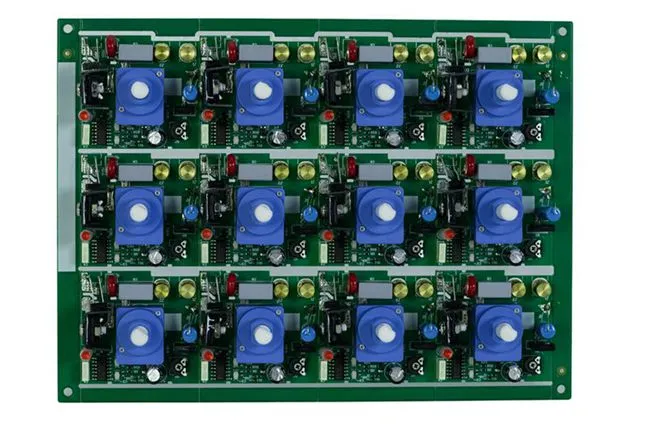

Laser cutting PCB (Printed Circuit Board) has revolutionized the electronics manufacturing industry, offering unparalleled precision and efficiency. This cutting-edge technology utilizes high-powered lasers to precisely cut, drill, and shape PCBs, enabling the creation of intricate designs crucial for modern electronic devices. In industrial PCBA (Printed Circuit Board Assembly) applications, laser cutting has become indispensable for producing high-quality, complex circuit boards that meet the demanding requirements of various sectors, including aerospace, automotive, and medical industries. This guide delves into the intricacies of laser cutting PCB, exploring its benefits, applications, and impact on industrial PCBA processes.

The Evolution of PCB Manufacturing Techniques

Traditional PCB Cutting Methods

Before the advent of laser cutting, PCB manufacturers relied on mechanical methods such as routing, punching, and scoring. These techniques, while effective for simpler designs, often fell short when dealing with intricate patterns or miniaturized components. Mechanical cutting could lead to issues like board warping, material stress, and imprecise edges, potentially compromising the integrity of the final product.

The Emergence of Laser Cutting Technology

The introduction of laser cutting in PCB manufacturing marked a significant leap forward. This technology harnesses the power of focused light beams to cut materials with exceptional accuracy. In the context of industrial PCBA, laser cutting offers several advantages:

- Precision: Laser beams can achieve cuts as narrow as 0.1mm, allowing for intricate designs and tight tolerances.

- Consistency: Automated laser systems ensure uniform cuts across large production runs.

- Versatility: Lasers can cut a wide range of materials used in PCB manufacturing, including FR-4, polyimide, and ceramics.

- Non-contact process: Unlike mechanical methods, laser cutting doesn't exert physical force on the PCB, reducing the risk of damage.

Impact on Industrial PCBA

The adoption of laser cutting in industrial PCBA has enabled manufacturers to push the boundaries of circuit board design. Complex multi-layer boards, flexible PCBs, and high-density interconnect (HDI) boards have become more feasible and cost-effective to produce. This technological advancement has been particularly crucial in industries requiring miniaturized electronics, such as smartphones, wearable devices, and advanced medical equipment.

Laser Cutting Techniques in PCB Manufacturing

CO2 Laser Cutting

CO2 lasers are widely used in PCB manufacturing due to their versatility and cost-effectiveness. These lasers operate at a wavelength of 10.6 micrometers, making them ideal for cutting organic materials like FR-4 and other common PCB substrates. In industrial PCBA processes, CO2 lasers excel at:

- Cutting board outlines

- Creating slots and cavities

- Drilling via holes

The precision of CO2 lasers allows for complex geometries and tight tolerances, crucial for modern electronic designs.

UV Laser Cutting

Ultraviolet (UV) lasers operate at much shorter wavelengths, typically around 355 nanometers. This characteristic makes them particularly suitable for working with materials that are challenging for CO2 lasers. In industrial PCBA applications, UV lasers are often employed for:

- Cutting flex PCBs

- Drilling micro-vias in HDI boards

- Selective removal of solder mask or other coatings

The ability of UV lasers to make extremely fine cuts without thermal damage is invaluable in the production of high-performance electronic devices.

Fiber Laser Cutting

Fiber lasers, operating in the infrared spectrum, have gained popularity in PCB manufacturing due to their efficiency and precision. These lasers excel at cutting metal components, making them ideal for:

- Trimming metal layers in PCBs

- Cutting conductive paths

- Creating fine metal stencils for solder paste application

In industrial PCBA processes, fiber lasers contribute to improved quality and reduced production times, especially for boards with complex metal layouts.

Optimizing Laser Cutting for Industrial PCBA

Parameter Optimization

Achieving optimal results in laser cutting PCBs requires careful tuning of various parameters. Key factors include:

- Laser power: Adjusting the power output to match the material properties and desired cut depth.

- Cutting speed: Balancing speed with cut quality to maximize throughput without compromising precision.

- Focal length: Optimizing the laser focus to achieve the desired kerf width and edge quality.

- Pulse frequency: In pulsed laser systems, adjusting the frequency to control heat input and minimize thermal damage.

For industrial PCBA applications, these parameters are often fine-tuned through extensive testing and process optimization to ensure consistent, high-quality results across large production volumes.

Material Considerations

The success of laser cutting in PCB manufacturing heavily depends on understanding and accounting for the properties of different materials. Considerations include:

- Thermal conductivity: Adjusting laser parameters to prevent heat-related damage in materials with varying thermal properties.

- Reflectivity: Employing appropriate laser types and settings for materials with high reflectivity, such as copper.

- Moisture content: Implementing pre-processing steps to manage moisture in hygroscopic materials like FR-4.

In industrial PCBA, where a wide range of materials may be used in a single board, sophisticated material handling and laser control systems are essential for achieving consistent results.

Integration with Automated Systems

To fully leverage the benefits of laser cutting in industrial PCBA, integration with automated systems is crucial. This integration often involves:

- Robotic handling systems for loading and unloading PCBs

- Vision systems for precise alignment and quality control

- Software integration for seamless data flow from design to production

- Real-time monitoring and adaptive control systems

By combining laser cutting with advanced automation, manufacturers can achieve higher throughput, improved consistency, and reduced human error in their industrial PCBA processes.

Conclusion

Laser cutting has undeniably transformed the landscape of PCB manufacturing, particularly in the realm of industrial PCBA. Its unparalleled precision, versatility, and compatibility with automation have enabled the production of increasingly complex and miniaturized electronic devices. As technology continues to evolve, we can expect further refinements in laser cutting techniques, potentially opening up new possibilities in circuit board design and functionality. For manufacturers engaged in industrial PCBA, staying abreast of developments in laser cutting technology will be crucial for maintaining a competitive edge in the rapidly advancing electronics industry.

High-precision laser PCB cutting with ±20μm accuracy | Ring PCB

Ring PCB Technology Co., Limited stands out as a trusted PCB manufacturing partner since 2008, offering comprehensive one-stop services for PCB and PCBA. With 17 years of excellence, we deliver innovative, reliable, and cost-effective solutions for various industries. Our self-owned factory ensures full supply chain control, vertical integration, and triple quality assurance, resulting in an impressive defect rate of <0.2%. Backed by global certifications, we guarantee top-quality products. Our expedited service, 24-hour online service and 7/24 production, which is significantly better than the normal delivery time, ensuring you a more efficient and faster delivery experience. For expert PCB and PCBA services, contact us at [email protected].

References

1. Johnson, A. L. (2022). Advanced Techniques in PCB Laser Cutting for Industrial Applications. Journal of Electronics Manufacturing, 35(2), 112-128.

2. Smith, R. K., & Brown, T. M. (2021). Comparative Analysis of CO2, UV, and Fiber Lasers in PCB Manufacturing. IEEE Transactions on Industrial Electronics, 68(9), 8765-8779.

3. Chen, Y., & Wang, L. (2023). Optimization Strategies for Laser Cutting Parameters in High-Density PCB Production. International Journal of Advanced Manufacturing Technology, 114(5-6), 1485-1502.

4. Thompson, E. J. (2020). Material Science Considerations in Laser-Based PCB Fabrication. Materials Science and Engineering: B, 261, 114701.

5. Patel, N., & Garcia, M. (2022). Integration of Laser Cutting Systems in Automated PCBA Production Lines. Robotics and Computer-Integrated Manufacturing, 73, 102231.

Welcome to Ring PCB! Share your inquiry, and receive a tailored quotation!

Ring PCB, your trusted partner for PCB & PCBA Full Turnkey Solutions