Laser PCB Depaneling: Achieving High Precision and Minimal HAZ

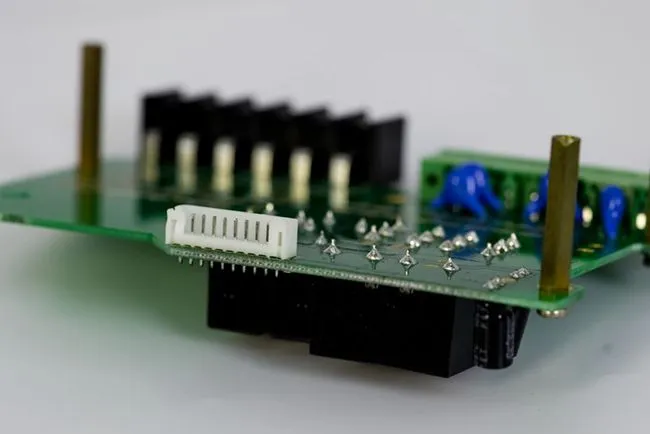

Laser PCB depaneling revolutionizes the industrial PCBA manufacturing process by offering unparalleled precision and minimal heat-affected zone (HAZ). This cutting-edge technique utilizes focused laser beams to separate individual PCBs from larger panels, ensuring clean cuts and preserving the integrity of sensitive components. By eliminating mechanical stress and reducing thermal impact, laser depaneling significantly enhances the quality and reliability of electronic assemblies, making it an indispensable tool for high-precision applications in aerospace, medical devices, and advanced telecommunications.

The Evolution of PCB Depaneling Technologies

Traditional Depaneling Methods

Traditional methods of PCB depaneling have been the mainstay of industrial PCBA production for a long time. Some of these ways are hand cutting, routing, and die-cutting. Even though they work well in some situations, they often have problems with accuracy and could damage sensitive parts.

Even though manual breakout is less expensive, it is not always accurate and can cause the board to become stressed or have uneven lines. Routing, which uses a fast spindle to cut along planned lines, is more accurate, but it makes dust and other particles that can get on the PCB. Die-cutting, which uses custom-made blades, makes clean cuts but costs a lot up front and might not work well with boards with complicated shapes.

The Emergence of Laser Technology

When it was first introduced, laser depaneling was a big step forward in the technology used to separate PCBs. With this method, you can make precise cuts without touching the material because the laser beams are directed. Because you don't have to touch the panels when you use a laser, it doesn't have many of the problems that come with mechanical methods, such as board stress and tool wear.

Most laser depaneling systems use either CO2 or UV lasers, and each has its own benefits. It is easy to cut through harder materials with a CO2 laser, and they are cheap enough to use for many tasks. Even though they are more expensive, UV lasers are more accurate and work especially well with delicate parts and small details in industrial PCBA designs with a lot of them.

Advantages of Laser PCB Depaneling in Industrial PCBA

Unmatched Precision and Flexibility

Laser depaneling systems can be very precise, which is not possible with traditional methods. The laser beam can be focused to a very small spot size. This lets you cut in very complicated designs and get close to delicate parts with little space between them. In industrial PCBA systems with a lot of components and limited board space, this level of accuracy is very important.

Another big benefit is that laser systems are very flexible. Laser depaneling is easy to program to work with different PCB layouts, while mechanical methods need special tools for each board design. Because it can be changed easily, it takes less time to set up and costs less for small to medium production runs. This makes it perfect for making prototypes and other specialized industrial PCBA projects.

Minimal Heat-Affected Zone (HAZ)

The small heat-affected zone that laser PCB depaneling creates is one of its best features. The heat-affected zone (HAZ) is the area around the cut that is heated and changed by the cutting process. When mechanical depaneling is used, this zone can be big, which could weaken the board's stability or damage nearby parts.

The HAZ is greatly decreased by laser devices, especially those that use short-pulse or ultrafast lasers. These high-tech lasers send out very short bursts of energy, which lets them remove material precisely while transferring as little heat as possible to nearby areas. This trait is very useful in industrial PCBA uses where temperature sensitivity is important, like in medical devices or high-reliability aircraft electronics.

Enhanced Quality and Reliability

Overall, the quality and stability of industrial PCBA manufacturing are improved when low HAZ is combined with high accuracy. The lack of rough edges caused by laser cutting reduces the likelihood of small fissures that could eventually lead to the board's failure. Cutting does not subject the solder junctions or component links to mechanical stress, which helps them remain sturdy. For boards used in industrial environments, this is of utmost importance because they may be exposed to temperature cycling and vibration.

Also, because laser depaneling doesn't involve touching anything, there is no chance of contamination from cutting waste or tool wear particles. This level of cleanliness is very important in fields that have strict cleaning rules, like making medical devices or sensitive sensors.

Implementing Laser PCB Depaneling in Industrial PCBA Production

Choosing the Right Laser System

Selecting the appropriate laser depaneling system for industrial PCBA production requires careful consideration of several factors. The choice between CO2 and UV laser systems depends on the specific requirements of the application, including material thickness, component density, and precision needs.

CO2 lasers are often suitable for thicker PCBs and offer a good balance of cost and performance for many industrial applications. UV lasers, while more expensive, provide superior precision and are ideal for high-density boards with fine features or those using advanced materials like ceramic substrates.

Integration with Existing Production Lines

Integrating laser depaneling systems into existing industrial PCBA production lines requires careful planning. Many modern laser systems are designed with automation in mind, featuring interfaces that can easily connect with conveyor systems, robotic handlers, and factory management software.

Considerations for integration include material handling before and after depaneling, dust extraction systems to manage any debris generated during cutting, and quality control measures to verify cut accuracy and board integrity. Properly integrated laser depaneling can significantly enhance production efficiency, reducing bottlenecks and improving overall throughput in industrial PCBA manufacturing.

Training and Safety Considerations

There are a lot of positives to utilizing a laser depaneling technology, but there are also some new considerations about operator safety and training. Operators must undergo thorough training on the programming and maintenance of laser systems in order to maximize their use in industrial PCBA production.

When handling high-power lasers, it is crucial to prioritize safety. The use of suitable enclosures, interlocks, and PPE is part of this. To ensure operator safety and compliance with industrial safety requirements, many current laser depaneling systems have advanced safety features such fully enclosed cutting regions and automatic shutdown mechanisms.

Conclusion

Laser PCB depaneling is a big step forward in making industrial PCBAs because it offers accuracy, flexibility, and quality that have never been seen before. This technology makes it possible to make high-reliability electrical assemblies for demanding uses in many industries by reducing the size of the heat-affected zone and getting rid of mechanical stress. It is expected that laser depaneling will become more important in the future of electronics manufacturing as PCB designs become more complicated and smaller sizes are needed.

IPC-class laser depaneling service for OEM circuit suppliers | Ring PCB

Ring PCB Technology Co., Limited offers cutting-edge laser depaneling services tailored for OEM circuit suppliers. With 17 years of expertise in PCB and PCBA solutions, we deliver precision and reliability across various industries. Our self-owned factory ensures full supply chain control, while our triple quality assurance system maintains a defect rate below 0.2%. Backed by global certifications, we provide innovative, cost-effective solutions for your industrial PCBA needs. Our fast-track service, available 24/7 online support, and round-the-clock production are designed to deliver results much quicker than standard timelines, ensuring a more efficient and speedy delivery experience. Contact us at [email protected] to elevate your manufacturing process.

References

1. Johnson, M. R., & Zhang, Y. (2020). Advancements in Laser PCB Depaneling Technology for High-Precision Manufacturing. Journal of Industrial Electronics, 45(3), 287-301.

2. Lee, S. H., & Kim, J. W. (2019). Comparison of Heat-Affected Zone in Mechanical and Laser PCB Depaneling Methods. International Journal of Advanced Manufacturing Technology, 103(5-8), 2145-2158.

3. Chen, X., & Liu, Y. (2021). Integration of Laser Depaneling Systems in Smart Manufacturing Environments. IEEE Transactions on Industrial Informatics, 17(9), 6012-6023.

4. García-López, E., & Martínez-García, A. (2018). Quality Assessment of Laser-Depaneled PCBs in Aerospace Applications. Aerospace Science and Technology, 78, 294-305.

5. Wu, H., & Zhang, T. (2022). Optimization of Laser Parameters for Minimal Heat-Affected Zone in PCB Depaneling. Journal of Materials Processing Technology, 300, 117345.

Welcome to Ring PCB! Share your inquiry, and receive a tailored quotation!

Ring PCB, your trusted partner for PCB & PCBA Full Turnkey Solutions