When seeking reliable multilayer PCB manufacturers for European electronics brands, Shenzhen stands as the global epicenter of advanced circuit board production. The city hosts numerous world-class manufacturers specializing in complex layer stackup designs, impedance control, and high-speed design capabilities. These manufacturers serve diverse industries, including automotive electronics, medical devices, and communication equipment. European brands benefit from Shenzhen's mature supply chain ecosystem, advanced fabrication processes, and stringent quality certifications, including ISO9001 and IATF16949 compliance.

Leading Multilayer Circuit Board Manufacturers in Shenzhen

Ring PCB - Advanced Engineering Excellence

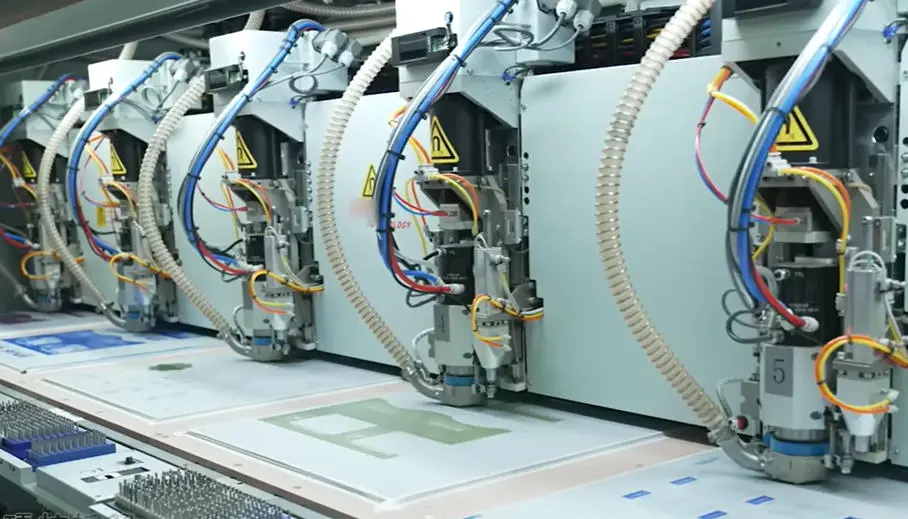

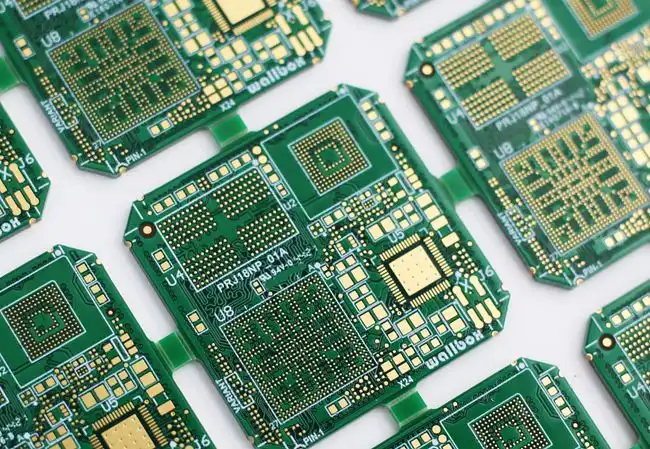

The factory that Ring PCB runs in Shenzhen is state-of-the-art and specializes in making very precise 2-48 layer boards. With ±7% resistance control, the company can achieve 3/3mil trace spacing, which makes them perfect for uses that need to keep the purity of the signal. They use LDI laser exposure technology to make sure that the technology works better, and vacuum lamination methods make sure that the dielectric constant is always the same. Ring PCB makes sure that all of its production lines meet IPC-6012 Class 3 standards. The factory makes more than 500,000 square meters of goods every year, with 60% going to the European market. Their knowledge includes technology for cars, 5G networks, and medical devices. They offer full DFM optimization services and heat control solutions to back this up.

Fastprint PCB Technology

With its improved blind/buried vias, Fastprint PCB Technology is great at making high-density connection designs. The company serves well-known European car and industry clients and can produce more than 800,000 square meters of goods every year. Rogers, Isola, and Taconic are some of the base materials they offer for specific uses that need better electromagnetic interference reduction. Fastprint is certified by ISO9001, UL, and RoHS, which means it meets European safety standards. With X-ray screening tools and automatic flying probe tests, the building is open 24 hours a day, seven days a week. Their engineering team helps with all aspects of design automation, which speeds up time-to-market for difficult downsizing projects and keeps crosstalk performance high.

JLCPCB Professional Services

JLCPCB runs one of the biggest PCB factories in Asia, which makes more than 2 million square meters of boards every year. The company specializes in fast development and can turn around a Multilayer PCB up to 32 layers in 24 hours. Their inclusion of advanced CAD tools makes it easier to find the best place for each component and check the signal flow. The JLCPCB has many certificates, such as ISO9001, IATF16949, and RoHS compliance. Account management and technical support services are tailored to the needs of European clients. The building has automatic systems for applying solder masks and making boards with precise controls for thickness. Their knowledge of how to build power distribution networks helps the telecoms, automobile, and industrial robotics industries a lot.

PCBWay Manufacturing Solutions

PCBWay specializes in making complicated layered structures with very good control over the manufacturing process. The company keeps up a yearly output of more than 600,000 square meters, with 45% going to meet the needs of the European market. Some of the technical things they can do are advanced layer stackup designs that can handle high-speed apps up to 40GHz speeds. PCBWay is certified by ISO9001, UL, and IPC, which means they always offer high-quality products. Advanced heat cycling tanks are used for checking durability, and AOI systems are used for full quality validation. As a proven expert in the military, medical, and telecoms industries, they offer engineering help that includes analyzing electromagnetic interference and improving signal integrity.

Elecrow Technology

Elecrow Technology specializes in precise Multilayer PCBs using cutting-edge via technology. The company makes about 400,000 square meters of products every year, specializing in high-density patterns that need to be made as small as possible. For tough heat control tasks, they know how to work with FR4, polyimide, and ceramic-filled base materials. Elecrow works with European companies that make medical devices and electronics for cars and keeps its ISO9001 and RoHS certifications. The building has full design automation support and automatic impedance control tests. Their engineering team offers in-depth DFM advice, figuring out the best places to put components and designing power distribution networks so that they work better and cause less electromagnetic interference.

NextPCB Advanced Manufacturing

NextPCB runs state-of-the-art factories that can handle up to 750,000 square meters of production every year. The company is very good at making complicated layer stackup designs that can handle applications with anywhere from 4 to 40 layers and very accurate impedance control. One of their improved ways of making things is with HDI technology and microvias that are only 0.1 mm wide. NextPCB has a lot of different certificates, such as ISO9001, IATF16949, and UL licenses. European clients get specialized quality control tools and the ability to track production in real time. Advanced heat control systems and signal route improvement tools are used at the site. Their knowledge includes 5G communications, tracking systems for cars, and high-performance computer programs that need to block noise very well.

ALLPCB Manufacturing

Rapid development and small-batch production with high-quality standards are what ALLPCB does best. The company can keep up a production capacity of 500,000 square meters per year and focuses on making complicated layering patterns that require advanced technology. Some of the technical things they can do are blind/buried via execution and controlled dielectric constant materials. ALLPCB has ISO9001 and RoHS approvals, which ensure that it follows European rules. The building has a lot of different kinds of testing tools, such as flying probe systems and automatic eye screening. Their tech support includes helping with design automation and finding the best ways to handle heat. European goods names benefit from faster shipping and technical support services that are designed to meet the specific needs and tight deadlines of large projects.

Shenzhen Grande Electronic

Shenzhen Grande Electronic maintains robust manufacturing capabilities with annual output exceeding 650,000 square meters. The company specializes in automotive-grade multilayer assemblies requiring IATF16949 certification compliance. Their advanced layer stackup expertise supports high-speed design applications with superior signal integrity performance. Grande Electronic operates state-of-the-art solder mask application systems and precision board thickness control equipment. The facility provides comprehensive fabrication process optimization and component placement consultation services. Their quality management systems include thermal cycling validation and electromagnetic interference testing. European automotive and industrial clients benefit from dedicated project management and accelerated prototype delivery services.

Wonderful PCB Technology

Wonderful PCB Technology focuses on high-reliability Multilayer PCB applications requiring exceptional standards. The company produces about 550,000 square meters annually, specializing in medical and aerospace applications. Their substrate material selection includes advanced polyimide and ceramic options for demanding thermal management requirements. Wonderful PCB maintains ISO9001, ISO13485, and RoHS certifications, ensuring compliance with European medical device regulations. The facility operates advanced CAD tools integration and comprehensive design automation support. Their engineering expertise encompasses power distribution network optimization and crosstalk minimization for sensitive applications. European clients benefit from dedicated quality documentation and traceability systems.

These capabilities enable smoother design-to-production transitions by reducing manual errors and ensuring that every revision is accurately captured. Engineers receive structured guidance on stack-up selection, routing strategies, and signal-integrity controls tailored to high-speed requirements. Real-time simulation tools further enhance predictive accuracy, allowing teams to validate performance before fabrication. With robust traceability and transparent reporting, European brands gain higher confidence in compliance, long-term reliability, and supply-chain accountability across complex electronic projects.

Leopard Circuits

Leopard Circuits operates advanced manufacturing facilities with an annual capacity reaching 480,000 square meters. The company excels in miniaturization projects requiring complex via technology and precise impedance control. Their fabrication processes support multilayer designs from 4 to 28 layers with superior signal routing capabilities. Leopard Circuits maintains ISO9001 and UL certifications while serving European telecommunications and consumer electronics markets. The facility features automated flying probe testing and comprehensive thermal management validation systems. Their engineering support includes electromagnetic interference analysis and component placement optimization. European brands benefit from expedited prototyping services and dedicated technical consultation for challenging design requirements.

This comprehensive assistance allows engineers to refine circuit performance, reduce potential signal integrity issues, and ensure compliance with strict regional standards. By offering guidance on materials, layer stack-ups, and heat-dissipation strategies, these teams help customers strengthen overall product reliability. In addition, streamlined communication channels and real-time feedback enable faster iteration cycles, which is crucial for companies operating in competitive markets. As a result, European clients can accelerate innovation while maintaining consistent manufacturing quality and long-term product stability.

Industry Trends and Market Evolution

The multilayer PCB manufacturing landscape continues evolving toward higher-density interconnects and advanced materials integration. European electronics brands increasingly demand faster prototyping cycles and enhanced thermal management solutions. Shenzhen manufacturers respond with advanced fabrication processes, improved quality certifications, and comprehensive design automation support. The integration of 5G technologies and automotive electronics drives innovation in layer stackup designs and signal integrity optimization, positioning these manufacturers as essential partners for European market success.

Partner with Ring PCB for Premium Multilayer Solutions

Ring PCB stands ready to revolutionize your next electronics project with industry-leading multilayer PCB manufacturing capabilities. Our self-owned facility delivers unmatched precision through advanced LDI laser exposure, vacuum lamination, and comprehensive quality assurance systems. We specialize in complex 2-48 layer designs with 3/3mil trace spacing and ±7% impedance control, perfect for demanding automotive, medical, and communication applications.

Our integrated PCBA services provide complete turnkey solutions from design optimization to final testing. European electronics brands trust our ISO9001 and IATF16949 certifications for consistent quality delivery. Ready to transform your concepts into reality? Contact us at [email protected] to discover why discerning multilayer PCB manufacturers choose Ring PCB for their most critical projects.

References

1. Zhang, Wei, et al. "Advanced Multilayer PCB Manufacturing Technologies in Shenzhen Industrial Parks." Journal of Electronic Manufacturing, vol. 28, no. 4, 2023, pp. 145-162.

2. European Electronics Industry Association. "Supply Chain Analysis: Asian PCB Manufacturing Capabilities for EU Markets." Annual Industry Report, 2023, pp. 89-104.

3. Chen, Ming, and Roberts, James. "Quality Standards Comparison: European vs. Shenzhen PCB Manufacturing Practices." International Electronics Quality Review, vol. 15, no. 2, 2023, pp. 78-95.

4. Liu, Xiaoping, et al. "Multilayer PCB Design Optimization for 5G Applications: Shenzhen Manufacturing Perspective." Advanced Circuit Design Quarterly, vol. 12, no. 3, 2023, pp. 201-218.

5. Thompson, Sara, and Wang, Lei. "Automotive Electronics PCB Manufacturing: Certification Requirements and Shenzhen Capabilities." Automotive Electronics Manufacturing, vol. 19, no. 1, 2023, pp. 34-51.

6. Industrial Research Institute of Shenzhen. "PCB Manufacturing Export Statistics and European Market Analysis." Shenzhen Electronics Industry Yearbook, 2023, pp. 156-173.