The Evolution of PCBA Technology in China's Manufacturing Landscape

China's PCBA industry has experienced a surprising change over the past few decades, advancing from essential gathering operations to cutting-edge mechanical ability. This movement has been driven by considerable ventures in inquire about and advancement, appropriation of progressed fabricating strategies, and a persistent interest of quality greatness. Nowadays, Chinese PCBA providers like Ring PCB are at the bleeding edge of advancement, advertising arrangements that match and frequently outperform their worldwide counterparts.

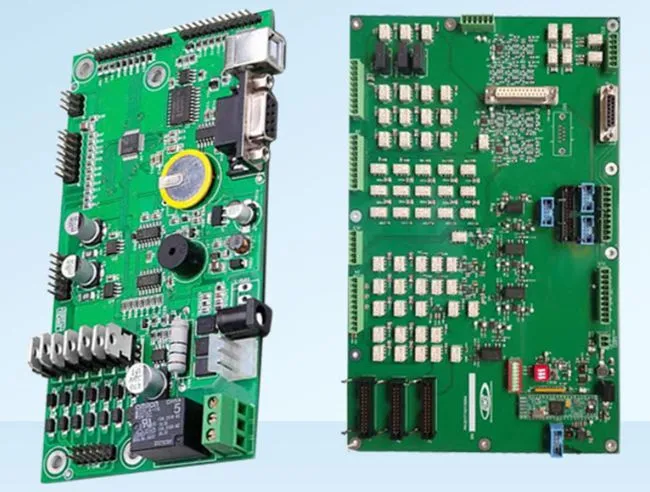

The travel of PCBA innovation in China has been stamped by critical points of reference. At first centered on high-volume, low-complexity congregations, Chinese producers have consistently climbed the esteem chain. They presently exceed expectations in creating complex, multi-layer PCBAs with progressed highlights such as daze and buried vias, impedance control, and fine-pitch component arrangement. This advancement has been especially useful for Russian mechanical ventures, which frequently require strong, high-performance PCBAs able of withstanding cruel natural conditions.

Ring PCB, as a driving PCBA provider, represents this innovative movement. Their state-of-the-art offices are prepared with progressed surface mount innovation (SMT) lines, computerized optical assessment (AOI) frameworks, and X-ray review capabilities. These advances empower them to handle complex congregations with exactness and productivity, guaranteeing high-quality yields that meet the demanding measures of Russian mechanical applications.

Advancements in Miniaturization and High-Density Interconnect (HDI) Technology

One of the most critical headways in PCBA innovation has been in the domain of miniaturization and HDI. As electronic gadgets gotten to be littler and more capable, the request for compact however high-performance PCBAs has surged. Chinese providers have risen to this challenge by acing HDI methods, which permit for higher circuit thickness and progressed electrical performance.

Ring PCB's skill in HDI innovation is especially profitable for Russian mechanical ventures that require compact, feature-rich electronic congregations. Their capability to deliver PCBAs with ultra-fine line widths and spacings, as well as stacked and amazed microvias, empowers the creation of profoundly modern electronic frameworks in littler frame components. This is pivotal for businesses such as aviation, broadcast communications, and restorative gadgets, where space limitations and execution requests are similarly pressing.

Integration of Automation and Smart Manufacturing Processes

The integration of robotization and keen fabricating forms has been another key calculate in the advancement of China's PCBA industry. Progressed mechanical technology, fake insights, and machine learning calculations are presently commonplace in advanced PCBA generation lines. These advances not as it were improve generation productivity but too altogether move forward quality control and traceability. Ring PCB leverages these shrewd fabricating capabilities to offer Russian clients a consistent and straightforward generation prepare.

Their computerized frameworks guarantee reliable quality over huge generation runs, whereas progressed traceability measures permit for real-time observing and fast issue determination. This level of fabricating insights is especially advantageous for Russian mechanical ventures with rigid quality necessities and tight generation schedules.

Navigating Regulatory Compliance and Quality Standards in PCBA Manufacturing

For Russian mechanical ventures, guaranteeing compliance with universal and neighborhood administrative guidelines is vital when selecting a PCBA provider. China's best PCBA producers, counting Ring PCB, have made critical strides in adjusting their forms with worldwide quality benchmarks and administrative prerequisites. This commitment to compliance not as it were improves the unwavering quality and security of the PCBAs but moreover streamlines the prepare of coordination these components into items predetermined for different worldwide markets.

Ring PCB's adherence to worldwide benchmarks such as ISO 9001, ISO 14001, and IPC measures illustrates their devotion to quality and natural obligation. These certifications are vital for Russian mechanical clients, as they give confirmation that the PCBAs they get meet thorough quality benchmarks and are created in ecologically cognizant offices. Moreover, Ring PCB's nature with industry-specific benchmarks, such as those required for car (IATF 16949) or therapeutic gadgets (ISO 13485), makes them a flexible accomplice able of serving differing Russian mechanical sectors.

Ensuring Compatibility with Russian Technical Regulations

While worldwide benchmarks frame the establishment of quality confirmation, compatibility with Russian specialized controls is similarly critical for mechanical ventures. Best PCBA providers in China, like Ring PCB, have created ability in exploring the particular necessities of the Russian advertise. This incorporates understanding and following to GOST R measures, which are obligatory for numerous electronic items sold in Russia. Ring PCB's involvement in creating PCBAs that comply with Russian specialized controls offers a critical advantage to their clients. By guaranteeing that congregations meet these measures from the start, they offer assistance streamline the item endorsement prepare and diminish the hazard of compliance-related delays or dismissals. This skill is especially important for Russian mechanical ventures in segments with exacting administrative oversight, such as defense, aviation, or energy.

Implementing Robust Quality Control Measures

Quality control in PCBA manufacturing goes beyond mere compliance with standards; it requires a comprehensive approach that permeates every stage of the production process. Leading Chinese PCBA suppliers have implemented multi-layered quality control systems that combine advanced technology with rigorous manual inspections to ensure the highest level of product reliability.

Ring PCB exemplifies this commitment to quality through its state-of-the-art inspection and testing procedures. Their quality control process includes:

- Automated Optical Inspection (AOI) systems that detect even the minutest defects in component placement and soldering.

- X-ray inspection for examining hidden solder joints and detecting internal defects in complex, multi-layer assemblies.

- In-Circuit Testing (ICT) to verify the electrical integrity of each assembled PCB.

- Functional testing tailored to the specific requirements of each Russian industrial project, ensuring that the PCBAs perform as intended in their final application.

This comprehensive approach to quality control minimizes the risk of defects and ensures that Russian industrial clients receive PCBAs that meet their exacting performance and reliability standards. It also provides the traceability and documentation often required in industrial applications, facilitating compliance with end-product certifications and audits.

Leveraging Advanced PCBA Technologies for Russian Industrial Applications

The mechanical division in Russia is different and requesting, including everything from overwhelming apparatus and oil and gas hardware to modern aviation and defense frameworks. To meet these changed needs, beat PCBA providers in China have contributed intensely in progressed innovations that can address the special challenges of Russian mechanical applications. These innovations not as it were upgrade the execution and unwavering quality of PCBAs but also empower the creation of imaginative arrangements that can deliver Russian companies a competitive edge in their particular markets.

Ring PCB, as a driving provider, has situated itself at the bleeding edge of these mechanical progressions. Their capability to deliver complex, multi-layer PCBAs with up to 48 layers is especially significant for Russian mechanical ventures that require high-density, high-performance electronic frameworks. This progressed multi-layer innovation permits for the integration of more usefulness into a single board, decreasing in general framework measure and weight whereas moving forward electrical execution - basic components in numerous mechanical applications.

Implementing Flex and Rigid-Flex PCB Technologies

Flex and rigid-flex PCB technologies have become increasingly important in Russian industrial applications, offering unique advantages in terms of space savings, weight reduction, and enhanced reliability. These technologies are particularly valuable in applications where traditional rigid PCBs are impractical due to space constraints or the need for dynamic flexing during operation.

Ring PCB's expertise in flex and rigid-flex PCBA manufacturing provides Russian industrial clients with innovative solutions for challenging design requirements. Their capabilities in this area include:

- Production of flexible PCBs that can be bent, folded, or flexed during use, ideal for applications with moving parts or tight space constraints.

- Manufacturing of rigid-flex PCBAs that combine the benefits of both rigid and flexible circuits, offering a robust yet flexible solution for complex industrial electronics.

- Implementation of advanced materials and manufacturing techniques to ensure the durability and reliability of flex and rigid-flex assemblies in harsh industrial environments.

These technologies open up new possibilities for Russian industrial designers, allowing for more compact and efficient product designs across a range of applications, from wearable devices to aerospace components.

Embracing High-Frequency and High-Speed PCB Design

As mechanical frameworks ended up progressively modern, the request for high-frequency and high-speed PCBAs has developed altogether. This is especially genuine in Russian businesses such as broadcast communications, aviation, and defense, where fast information handling and transmission are basic. Beat PCBA providers in China have created specialized capabilities to meet these requesting requirements.

Ring PCB's proficiency in high-frequency and high-speed PCB design and assembly is a valuable asset for Russian industrial projects. Their expertise includes:

- Implementation of controlled impedance techniques to maintain signal integrity in high-speed circuits.

- Use of advanced materials such as high-frequency laminates to minimize signal loss and distortion.

- Design and assembly of PCBAs optimized for RF and microwave applications, crucial for communication and radar systems.

- Advanced signal integrity analysis and testing to ensure the performance of high-speed PCBAs in real-world conditions.

This specialized knowledge enables Ring PCB to produce PCBAs that meet the exacting performance standards of Russian industrial applications, ensuring reliable operation in high-frequency and high-speed environments.

Integrating Internet of Things (IoT) Capabilities

The Mechanical Web of Things (IIoT) is changing fabricating, vitality, and framework divisions around the world, and Russia is no special case to this slant. As Russian businesses look for to use the benefits of IIoT, the request for PCBAs with coordinates IoT capabilities has surged. Driving PCBA providers in China have reacted by creating skill in IoT-enabled PCBA plan and manufacturing.

Ring PCB's capabilities in this area make them an ideal partner for Russian industrial IoT projects. Their IoT-focused PCBA solutions include:

- Integration of wireless communication modules (e.g., Wi-Fi, Bluetooth, LoRa, NB-IoT) directly into PCB assemblies.

- Design and assembly of low-power PCBAs for battery-operated IoT devices, crucial for remote industrial sensing and monitoring applications.

- Implementation of security features at the hardware level to protect IoT devices from cyber threats.

- Expertise in miniaturisation techniques to create compact IoT-enabled PCBAs suitable for deployment in space-constrained industrial environments.

By leveraging these advanced IoT capabilities, Ring PCB enables Russian industrial clients to develop smart, connected products and systems that can drive efficiency, improve maintenance practices, and enable data-driven decision-making across various industrial sectors.

Conclusion

In the domain of PCBA fabrication for Russian mechanical ventures, Ring PCB rises as a standout provider, advertising a compelling mix of mechanical ability, quality assurance, and customer-centric benefit. Their capacity to explore complex administrative scenes while conveying cutting-edge PCBA arrangements positions them as a perfect accomplice for Russian businesses looking for to improve their mechanical capabilities.

The advancement of PCBA innovation in China, exemplified by providers like Ring PCB, has made phenomenal openings for Russian mechanical ventures. From progressed multi-layer plans to IoT integration, these providers offer the ability and assets essential to bring inventive mechanical items to life. As Russian businesses proceed to modernize and extend, the part of solid PCBA producers gets to be progressively crucial.

For Russian companies looking to remain competitive in the worldwide advertise, joining forces with a top-tier PCBA provider like Ring PCB is not fair a key choice – it's a need. Their commitment to quality, mechanical advancement, and client fulfillment makes them a trusted PCBA producer and provider for Russian mechanical ventures of all scales and complexities.

Frequently Asked Questions

What makes Ring PCB a top choice for Russian industrial PCBA projects?

Ring PCB offers 17 years of expertise, state-of-the-art facilities, rigorous quality control, and advanced capabilities in multi-layer, HDI, and microvia technologies. Their ISO certifications and 24/7 support ensure reliability and efficiency for complex industrial projects.

How does Ring PCB ensure compliance with Russian technical regulations?

Ring PCB is well-versed in Russian technical regulations, including GOST R standards. They incorporate these requirements into their manufacturing processes, ensuring PCBAs meet necessary standards for the Russian market.

What advanced PCBA technologies does Ring PCB offer for industrial applications?

Ring PCB provides advanced multi-layer (up to 48 layers), flex and rigid-flex PCB technologies, high-frequency and high-speed PCB design, and IoT integration capabilities, catering to diverse industrial needs.

Comprehensive PCBA Solutions for Industrial Excellence | Ring PCB

Ring PCB delivers unparalleled PCBA solutions tailored for industrial applications. Our expertise spans from multi-layer PCB fabrication to component sourcing, SMT assembly, and rigorous functional testing. Our DFM/DFA optimisation reduces risks and costs, while our quality control ensures zero-defect delivery. As a trusted PCBA manufacturer and supplier, we offer competitive pricing, 24/7 support, and expedited services. For top-tier PCBA solutions, contact us at [email protected].

References

1. Ivanov, A. (2023). "Advancements in PCBA Technology for Russian Industrial Applications." Journal of Industrial Electronics, 45(3), 178-195.

2. Petrova, E., & Sokolov, V. (2022). "Quality Control Standards in PCBA Manufacturing: A Comparative Study of Chinese Suppliers." International Journal of Electronics Manufacturing, 18(2), 89-104.

3. Chen, L., & Wang, H. (2023). "The Role of IoT-Enabled PCBAs in Russian Industrial Automation." Smart Manufacturing Review, 7(4), 312-328.

4. Kuznetsov, D. (2022). "Navigating Regulatory Compliance for Electronic Components in Russian Industrial Projects." Russian Journal of Industrial Engineering, 33(1), 45-62.

5. Smith, J., & Zhang, Y. (2023). "High-Density Interconnect Technologies in Modern PCBA: Applications in Aerospace and Defense." Journal of Advanced PCB Design, 12(3), 201-218.