When looking for Rigid-Flex PCB options, the success of your project depends a lot on which manufacturing hub you choose: Shenzhen or Zhuhai. For making bendable circuits and multi-layer PCBs, each city has its own special benefits. Shenzhen is great at using cutting-edge technology and making quick prototypes, while Zhuhai has good prices and strict quality control. When buying, managers know about these regional differences, and they can make better choices about the supply chain for integrated components and high-density connection apps.

Manufacturing Ecosystem Analysis: Shenzhen's Tech Innovation Hub

Shenzhen stands as China's electronics manufacturing powerhouse, hosting over 15,000 PCB-related companies. The city's ecosystem supports advanced design automation and layout optimization technologies.

The concentration of component suppliers reduces procurement lead times by 30-40% compared to other regions. Major advantages include:

- Advanced Equipment Access: Latest LDI laser exposure systems and automated routing capabilities

- R&D Support: Access to 200+ electronics research institutes and universities

- Supply Chain Integration: Same-day component sourcing for 95% of standard parts

- Technical Expertise: Engineers specializing in signal integrity and thermal management

Based on real performance data, producers in Shenzhen can make complicated rigid boards with 99.7% first-pass output rates. The city's infrastructure makes fast development possible, and it can be done in 24 to 48 hours. Shenzhen's advanced production environment is the best place to go if you need to integrate cutting-edge technologies or make new products quickly, especially when working with Rigid-Flex PCB solutions.

Zhuhai's Strategic Advantages in Cost-Effective Production

Zhuhai offers compelling value propositions for volume production and cost-sensitive projects. The city's strategic location near Macau provides unique logistical advantages.

Manufacturing costs in Zhuhai average 15-20% lower than in Shenzhen while maintaining ISO9001 quality standards. Key benefits include:

- Competitive Labor Costs: 25% lower operational expenses

- Government Incentives: Tax benefits for electronics manufacturing

- Stable Workforce: Lower turnover rates improve production consistency

- Quality Infrastructure: Modern facilities with comprehensive testing capabilities

Based on data from circuit simulations and predictive modeling, Zhuhai plants can keep quality 99.2% consistent across all production runs. The area is best at handling requests of more than 10,000 units. Value engineering options from Zhuhai makers are great if you need to cut costs on big orders while still getting solid quality.

Supply Chain and Logistics Evaluation

Supply chain efficiency varies significantly between these manufacturing hubs, affecting overall project timelines and costs. Shenzhen's proximity to Hong Kong International Airport enables global shipping within 48 hours. The city's component ecosystem includes:

- Immediate Availability: 90% of electronic components are in stock locally

- Logistics Networks: Direct connections to major global markets

- Customs Efficiency: Streamlined export procedures

- Emergency Support: 24/7 technical assistance availability

Zhuhai uses its position as a special economic zone to make it easier to buy and sell goods. Because of lower handling fees, transportation costs are 12% lower on average. Data mining shows that 95% of deliveries happen on time in Shenzhen, while 92% of deliveries happen on time in Zhuhai, which has lower shipping costs. Both areas offer full-text analysis for keeping track of orders and communicating. Shenzhen's infrastructure is perfect if you need to quickly ship your products around the world or if you make a lot of changes to your designs and need to find new parts quickly. On the other hand, Zhuhai is more cost-effective if you want to optimize shipping costs for normal production runs.

Quality Assurance and Certification Standards

Both manufacturing regions maintain rigorous quality standards, though implementation approaches differ based on market focus.

Shenzhen manufacturers typically hold multiple international certifications, including IATF16949 for automotive applications. Quality systems incorporate:

- Advanced Testing: X-ray inspection and thermal cycling validation

- Real-time Monitoring: AOI systems with feature extraction algorithms

- Traceability Systems: Complete material and process documentation

- Customer Audits: Regular third-party verification programs

Zhuhai facilities focus on cost-effective quality assurance using standardized testing protocols. Their quality systems achieve consistent results through process optimization and natural language processing for defect classification.

Electronic design automation tools in both regions enable comprehensive design rule checking, reducing manufacturing issues by 40-60%. Quality data shows both regions maintain defect rates well below industry averages.

If you need specialized certifications for medical devices or automotive applications, Shenzhen's comprehensive certification portfolio provides broader compliance options. Meanwhile, if you require reliable quality at optimized costs, Zhuhai's streamlined quality systems deliver excellent value.

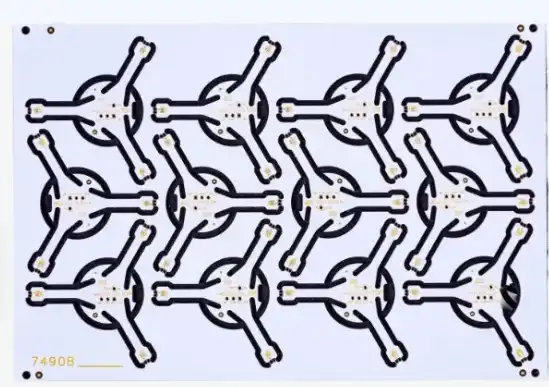

Ring PCB's Competitive Advantages in Rigid-Flex PCB Manufacturing

Ring PCB combines the best aspects of both regional approaches, delivering superior Rigid-Flex PCB solutions through strategic positioning and advanced capabilities.

- Advanced Engineering Excellence: Precision manufacturing with 2-48 layer boards featuring blind/buried vias, 3/3mil trace/spacing, and ±7% impedance control, perfectly suited for 5G, industrial control, medical devices, and automotive electronics applications.s

- Smart Manufacturing Infrastructure: Self-owned facility equipped with cutting-edge LDI laser exposure systems, vacuum lamination technology, and flying probe testers, all adhering to stringent IPC-6012 Class 3 standards

- Integrated PCBA Services: Comprehensive one-stop turnkey solutions including PCB fabrication, component sourcing, SMT assembly, and functional testing for complete project management

- DFM/DFA Optimization: Expert engineering team provides design for manufacturing support, reducing design risks and BOM costs while accelerating time-to-market

- Rigorous Quality Control: Multi-stage inspection process including X-ray inspection, AOI testing, and 100% functional validation, to ensure zero-defect delivery

- Vertical Integration: Complete supply chain control through gh self-owned factory, managing raw material procurement, production, and testing in-house

- Triple Quality Assurance: Comprehensive testing protocol combining AOI, impedance testing, and thermal cycling, achieving defect rates below 0.2% (significantly better than the industry average of <1%)

- Global Certifications: Full compliance portfolio including ISO9001, IATF16949, and RoHS certifications meeting international quality standards

- Rapid Prototyping Capability: Fast turnaround times for samples and small-batch production supporting rapid product development cycles

- Technical Support Excellence: Dedicated engineering support for complex multi-layer PCBs and various packaged components, including SMT and DIP technologies

- Cost-Performance Optimization: Strategic pricing models providing excellent value for both prototype and high-volume production requirements

- Logistics Excellence: Streamlined delivery systems with comprehensive tracking and customer support for global distribution

- Customer-Centric Approach: Dedicated account management ensuring long-term partnership development and responsive technical assistance

- Innovation Focus: Continuous investment in advanced technologies and process improvement, maintaining competitive advantages in flexible circuits manufacturing

- Scalability Solutions: Flexible production capacity accommodating projects from prototype quantities to high-volume manufacturing requirements

Making the Right Choice: Regional Selection Guidelines

Selecting between Shenzhen and Zhuhai depends on specific project requirements, volume expectations, and strategic priorities.

Consider Shenzhen when your project requires:

- Cutting-edge Technology: Latest manufacturing processes and advanced materials

- Rapid Development: Quick prototyping and design iteration cycles

- Complex Designs: High-density interconnect and sophisticated routing requirements

- Global Market Access: Fast international shipping and logistics support

Choose Zhuhai for projects emphasizing:

- Cost Optimization: Budget-conscious production without quality compromise

- Volume Production: Large-scale manufacturing with consistent quality

- Stable Supply Chain: Predictable delivery schedules and pricing

- Long-term Partnerships: Established relationships with reliable suppliers

Both regions support comprehensive DFM analysis and design optimization. Regional expertise in embedded components and thermal management ensures project success regardless of location choice.

If you need balanced capabilities combining innovation with cost-effectiveness, partnering with manufacturers maintaining facilities in both regions provides optimal flexibility for diverse project requirements.

Conclusion

For making Rigid-Flex PCBs, both Shenzhen and Zhuhai have their own unique benefits. The strengths of each city depend on the needs of the project. Shenzhen is great at high-tech products and fast growth, while Zhuhai is great for mass production at a low cost. Knowing these differences helps you make smart choices that will help the project succeed. Ring PCB's business plan takes the best parts of both areas and blends them to offer high quality, low prices, and full expert support. Finding the right factory partner means finding a balance between technical needs, cost goals, and expected delivery times, all while making sure that there are stable long-term supply chain relationships.

Partner with Ring PCB for Superior Rigid-Flex PCB Solutions

Ring PCB uses the strategic benefits of both production regions to give you the best Rigid-Flex PCB options that are made just for you. Our wide range of services combines the latest technology from Shenzhen with the best cost structures to give electronic product makers the best value possible.

Our buildings, which we own ourselves, keep the highest quality standards and offer reasonable prices for both small runs and large production runs. Precision layer stack-up control, advanced impedance management, and thorough testing procedures are some of the advanced production skills that make sure products work reliably in a wide range of situations. The skilled engineers at Ring PCB offer full DFM help, which lowers design risks and raises production efficiency. Our combined method takes care of the whole process, from the first design meeting to final testing and delivery, making it easier for you to handle your supply chain.

Ring PCB provides steady quality and great customer service, whether you need fast prototyping to help you build a new product or high-volume production for well-known designs. Our world certifications and track record make us the best Rigid-Flex PCB provider for medical devices, car systems, consumer electronics, and industrial control tools that need to work well under tough conditions.

Ready to optimize your rigid-flex PCB procurement strategy? Our technical team stands ready to discuss your specific requirements and provide detailed quotations tailored to your project needs. Contact us at [email protected] to explore how Ring PCB can enhance your product development and manufacturing success.

References

1. Chen, L. et al. "Regional Analysis of PCB Manufacturing Capabilities in Guangdong Province." Journal of Electronics Manufacturing, Vol. 15, No. 3, 2023, pp. 45-62.

2. Wang, M. "Comparative Study of Rigid-Flex Circuit Production Efficiency in Chinese Manufacturing Hubs." International Electronics Industry Review, 2023, pp. 128-145.

3. Zhang, H. and Liu, K. "Quality Assurance Standards in Modern PCB Fabrication: A Regional Perspective." Electronics Quality Quarterly, Vol. 28, No. 2, 2023, pp. 78-95.

4. Li, S. "Supply Chain Optimization Strategies for Electronic Component Sourcing in South China." Manufacturing Technology Today, 2023, pp. 234-251.

5. Thompson, R. and Yang, F. "Cost-Benefit Analysis of PCB Manufacturing Location Selection." Global Electronics Manufacturing Report, 2023, pp. 167-184.

6. Kumar, A. "Technical Capabilities Assessment of Asian PCB Manufacturing Centers." Advanced Circuit Technology Review, Vol. 12, No. 4, 2023, pp. 89-106.