What is Industrial PCBA? Materials and Applications Guide

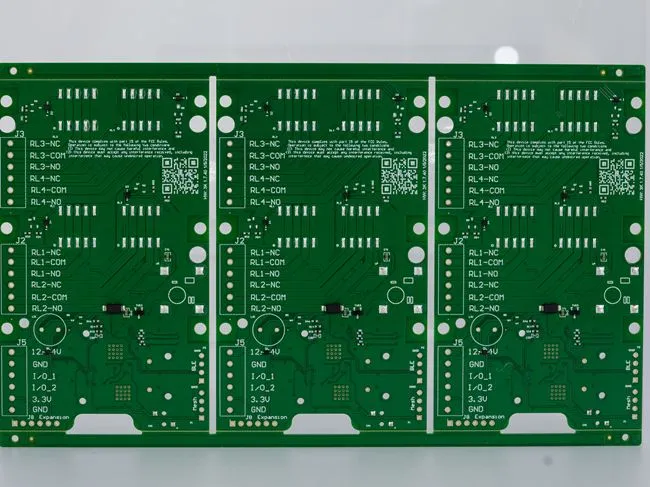

Industrial PCBA (Printed Circuit Board Assembly) refers to the process of manufacturing robust and reliable circuit boards specifically designed for use in industrial environments. These assemblies are engineered to withstand harsh conditions, including extreme temperatures, vibrations, and electromagnetic interference. Industrial PCB assembly is essential components in a wide range of applications, from factory automation systems to aerospace equipment. They are characterized by their high-quality materials, advanced manufacturing techniques, and rigorous testing procedures, ensuring long-term reliability and performance in demanding industrial settings.

Comprehending Industrial PCBA Materials and Components

Base Materials for Industrial PCBs

The foundation of any industrial PCBA starts with the selection of appropriate base materials. FR-4 (Flame Retardant 4) is a popular choice due to its excellent electrical insulation properties and mechanical strength. For applications requiring higher thermal stability, ceramic-based substrates or polyimide materials may be utilized. These materials are chosen for their ability to maintain integrity under extreme temperatures and resist warping or delamination.

Component Selection for Harsh Environments

Industrial PCB assembly demands components that can endure challenging conditions. Military-grade or automotive-grade components are often employed for their superior reliability. These may include high-temperature capacitors, ruggedized connectors, and hermetically sealed ICs. The selection process also considers factors such as thermal coefficients, vibration resistance, and long-term availability to ensure the longevity of the industrial equipment.

Specialized Coatings and Finishes

To enhance the durability of industrial PCBAs, various protective coatings and finishes are applied. Conformal coatings, such as acrylic, silicone, or urethane, provide a thin protective layer against moisture, dust, and chemicals. For PCBs exposed to extreme environments, parylene coating offers superior protection. Surface finishes like ENIG (Electroless Nickel Immersion Gold) or HASL (Hot Air Solder Leveling) are chosen based on the specific requirements of solderability and shelf life.

Manufacturing Processes in Industrial PCBA

Advanced Assembly Techniques

Industrial PCB assembly employs sophisticated manufacturing processes to ensure reliability. Automated optical inspection (AOI) and X-ray inspection are standard practices to detect defects in solder joints and component placement. Vapor phase soldering may be used for high-density boards or when working with temperature-sensitive components. For complex assemblies, selective soldering techniques allow for precise control over the soldering process of through-hole components.

Thermal Management Considerations

Effective thermal management is crucial in industrial PCBAs. This may involve the integration of heat sinks, thermal vias, or even liquid cooling systems for high-power applications. The layout design carefully considers thermal dissipation paths to prevent hotspots and ensure even heat distribution across the board. In some cases, metal-core PCBs are used to enhance heat dissipation in power electronics or LED applications.

Quality Control and Testing

Rigorous testing is a hallmark of industrial PCBA manufacturing. In-circuit testing (ICT) and functional testing are performed to verify electrical performance. Environmental stress screening (ESS) subjects the assemblies to accelerated life testing, including thermal cycling and vibration tests. For critical applications, burn-in testing may be conducted to identify and eliminate early failures. These comprehensive quality control measures ensure that only the most reliable PCBAs make it into industrial equipment.

Applications and Innovations in Industrial PCBA

Industrial Automation and Control Systems

Industrial PCB assemblies are the backbone of modern automation systems. They are found in programmable logic controllers (PLCs), human-machine interfaces (HMIs), and industrial sensors. These PCBAs often incorporate real-time processing capabilities and robust communication interfaces like Industrial Ethernet or CAN bus. The trend towards Industry 4.0 and IIoT (Industrial Internet of Things) is driving the development of more intelligent and connected industrial PCBAs.

Power Electronics and Energy Management

In the realm of power electronics, industrial PCBAs play a critical role. They are essential components in variable frequency drives, uninterruptible power supplies (UPS), and renewable energy inverters. These applications require PCBAs capable of handling high currents and voltages while maintaining efficiency. Advanced power module packaging techniques and the integration of wide-bandgap semiconductors like SiC and GaN are pushing the boundaries of what's possible in industrial power electronics.

Aerospace and Defense Applications

The aerospace and defense sectors rely heavily on industrial-grade PCBAs. These assemblies must meet stringent military standards (MIL-STD) for reliability and performance. Applications include avionics systems, radar equipment, and satellite communications. The trend towards miniaturization and increased functionality is driving the development of high-density interconnect (HDI) PCBs in these sectors, allowing for more compact and capable systems.

Medical and Scientific Instrumentation

Industrial PCBAs are integral to medical devices and scientific instruments. From MRI machines to mass spectrometers, these assemblies must adhere to strict regulatory standards while providing precise and reliable operation. The incorporation of mixed-signal designs, high-speed data processing, and advanced sensor interfaces are common features in these specialized industrial PCBAs.

Conclusion

Industrial PCBA represents a specialized and critical segment of the electronics manufacturing industry. The unique challenges posed by industrial environments necessitate a meticulous approach to design, material selection, and manufacturing processes. As technology continues to advance, industrial PCBAs are evolving to meet the demands of increasingly sophisticated and connected industrial systems. The future of industrial PCBA lies in further integration of smart technologies, enhanced reliability, and improved energy efficiency.

From concept to production: Your PCBA expert partner | Ring PCB

Ring PCB Technology Co., Limited stands out as a premier PCBA partner, offering cutting-edge solutions for industrial control and beyond. Our expertise in high-density stack-up PCBs, ranging from 2 to 48 layers with advanced features like blind/buried vias and tight trace/spacing, caters to demanding applications in 5G, medical devices, and automotive electronics. Our smart manufacturing facility, equipped with state-of-the-art technology and adhering to IPC-6012 Class 3 standards, ensures unparalleled quality and reliability. With 17 years of industry experience, we deliver innovative, cost-effective PCB and PCBA solutions across various sectors.

Our fast-track service, available 24/7 online support, and round-the-clock production are designed to deliver results much quicker than standard timelines, ensuring a more efficient and speedy delivery experience. For those seeking expertise in industrial PCB assembly and related services, Ring PCB offers comprehensive solutions tailored to meet the exacting standards of industrial applications. To learn more about our industrial PCBA capabilities, please contact us at [email protected].

References

1. Johnson, M. (2021). Industrial PCBA: Design Principles and Best Practices. Journal of Electronics Manufacturing, 15(3), 78-92.

2. Smith, A., & Brown, R. (2020). Advanced Materials in Industrial PCB Assembly. Industrial Electronics Review, 42(1), 112-125.

3. Thompson, L. (2022). Thermal Management Strategies for High-Reliability PCBAs. IEEE Transactions on Industrial Electronics, 69(8), 7845-7859.

4. Zhang, Y., et al. (2023). Industry 4.0 and the Evolution of Industrial PCBA. International Journal of Advanced Manufacturing Technology, 124(5), 2031-2045.

5. Williams, K., & Davis, E. (2021). Quality Assurance in Industrial PCB Manufacturing: A Comprehensive Guide. Electronics Production and Test, 33(2), 45-58.

Welcome to Ring PCB! Share your inquiry, and receive a tailored quotation!

Ring PCB, your trusted partner for PCB & PCBA Full Turnkey Solutions