Advanced Manufacturing Capabilities: The Cornerstone of PCB Factory Reliability

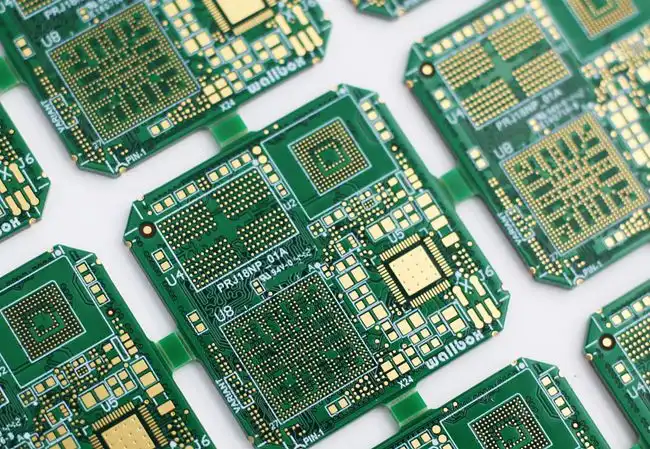

When evaluating the reliability of a PCB factory, one of the most crucial factors to consider is its manufacturing capabilities. Advanced manufacturing processes and state-of-the-art equipment are vital for producing high-quality printed circuit boards that meet the demanding requirements of modern electronics.

Cutting-Edge Equipment and Technology

A reliable PCB factory invests in cutting-edge equipment and technology to stay competitive in the rapidly evolving electronics industry. This includes advanced machinery for PCB fabrication, such as high-precision drilling and routing systems, automated optical inspection (AOI) equipment, and X-ray inspection systems. These technologies enable the factory to produce complex, multi-layer boards with tight tolerances and ensure consistent quality across production runs.

Moreover, a state-of-the-art facility should be equipped with advanced capabilities like LDI (Laser Direct Imaging) systems for precise pattern transfer, vacuum lamination for improved layer bonding, and flying probe testers for comprehensive electrical testing. These technologies contribute to the overall reliability and performance of the manufactured PCBs.

Expertise in High-Density Designs

As electronic devices become more compact and sophisticated, the demand for high-density PCB designs continues to grow. A reliable PCB factory should demonstrate expertise in producing high-density interconnect (HDI) boards, including the ability to fabricate boards with fine line widths and spacings, micro vias, and buried or blind vias.

The capability to manufacture boards with a high layer count (e.g., 2-48 layers) and maintain tight impedance control (such as ±7%) is also indicative of a factory's advanced manufacturing prowess. These capabilities are particularly important for applications in industries like 5G telecommunications, industrial control systems, medical devices, and automotive electronics.

Flexibility and Scalability

A reliable PCB factory should be able to handle a wide range of production volumes, from small prototype runs to large-scale manufacturing. This flexibility allows the factory to cater to diverse customer needs and adapt to changing market demands. Additionally, the ability to scale production quickly without compromising quality is a valuable attribute that demonstrates the factory's operational efficiency and reliability.

Quality Control and Compliance: Ensuring PCB Factory Excellence

Quality control processes and adherence to industry standards are paramount in assessing the reliability of a PCB factory. These factors not only ensure the production of high-quality PCBs but also demonstrate the factory's commitment to excellence and customer satisfaction.

Robust Quality Management Systems

A reliable PCB factory implements comprehensive quality management systems to maintain consistent product quality throughout the manufacturing process. This includes rigorous inspection procedures at various stages of production, from raw material verification to final product testing.

The use of statistical process control (SPC) techniques and continuous improvement methodologies, such as Six Sigma or Lean Manufacturing, are indicators of a factory's dedication to quality. These approaches help identify and eliminate sources of defects, reduce variability, and optimize production processes.

Adherence to Industry Standards

Compliance with recognized industry standards is a crucial aspect of PCB factory reliability. A reputable manufacturer should adhere to standards such as IPC-6012 (Qualification and Performance Specification for Rigid Printed Boards), which defines requirements for PCB quality and reliability.

Certifications like ISO 9001 for quality management systems and ISO 14001 for environmental management demonstrate a factory's commitment to maintaining high standards in its operations. Additionally, certifications specific to certain industries, such as AS9100 for aerospace or IATF 16949 for automotive, may be relevant depending on the target market.

Traceability and Documentation

A reliable PCB factory maintains detailed records and documentation throughout the manufacturing process. This includes material traceability, process parameters, test results, and quality control data. Robust documentation practices not only facilitate problem-solving and continuous improvement but also provide customers with confidence in the factory's quality control measures.

Customer Service and Technical Support: Hallmarks of a Trustworthy PCB Factory

Beyond manufacturing capabilities and quality control, the level of customer service and technical support provided by a PCB factory is a significant indicator of its reliability and commitment to customer satisfaction.

Responsive Communication

A reliable PCB factory prioritizes clear and timely communication with its customers. This includes prompt responses to inquiries, regular updates on order status, and proactive notifications of any issues or delays that may affect production. Effective communication channels, such as dedicated account managers or online portals for order tracking, contribute to a positive customer experience and build trust in the manufacturer's reliability.

Technical Expertise and Design Support

A trustworthy PCB factory offers technical expertise and design support to help customers optimize their PCB designs for manufacturability and performance. This may include design for manufacturing (DFM) reviews, stackup recommendations, and guidance on material selection. The ability to provide valuable technical insights demonstrates the factory's commitment to ensuring the success of its customers' projects.

Flexibility and Problem-Solving

Reliable PCB factories exhibit flexibility in accommodating customer requirements and demonstrate strong problem-solving skills when faced with challenges. This may include the ability to handle rush orders, make last-minute design changes, or develop innovative solutions for complex manufacturing requirements. A factory's willingness to go above and beyond to meet customer needs is a strong indicator of its reliability and customer-centric approach.

Conclusion

Selecting a reliable PCB factory is crucial for ensuring the success of electronic product development and manufacturing projects. By evaluating factors such as advanced manufacturing capabilities, quality control processes, adherence to industry standards, and customer service, electronics manufacturers can identify trustworthy PCB suppliers and manufacturers that meet their specific needs. A dependable PCB factory partner not only delivers high-quality printed circuit boards but also contributes valuable expertise and support throughout the production process, ultimately enhancing the overall success and competitiveness of electronic products in the market.

FAQ

What are the key factors to consider when choosing a reliable PCB factory?

Key factors include advanced manufacturing capabilities, quality control processes, adherence to industry standards, customer service, and technical expertise.

How important is a PCB factory's ability to produce high-density designs?

It's crucial, especially for applications in industries like 5G, industrial control, medical devices, and automotive electronics that require compact and sophisticated PCBs.

What industry standards should a reliable PCB factory adhere to?

Important standards include IPC-6012 for rigid PCBs, ISO 9001 for quality management, and industry-specific certifications like AS9100 for aerospace or IATF 16949 for automotive.

Experience Precision and Reliability in PCB Manufacturing | Ring PCB

At Ring PCB, we embody the qualities of a reliable PCB factory, offering advanced engineering capabilities for precision PCB manufacturing. Our high-density stack-up expertise, encompassing 2-48 layer boards with blind/buried vias and tight tolerances, caters to demanding industries. Our smart manufacturing facility, equipped with cutting-edge technology, ensures consistent quality and adherence to IPC-6012 Class 3 standards. Experience the difference of working with a trusted PCB manufacturer. Contact us at [email protected] to discuss your PCB requirements.