Factors Influencing Multilayer PCB Manufacturing Lead Times

Multilayer PCB manufacturing is a complex process that involves numerous steps and variables. Understanding these factors can help you better estimate and manage production timelines for your projects. Let's explore some key elements that impact lead times in multilayer PCB production:

Board Complexity and Layer Count

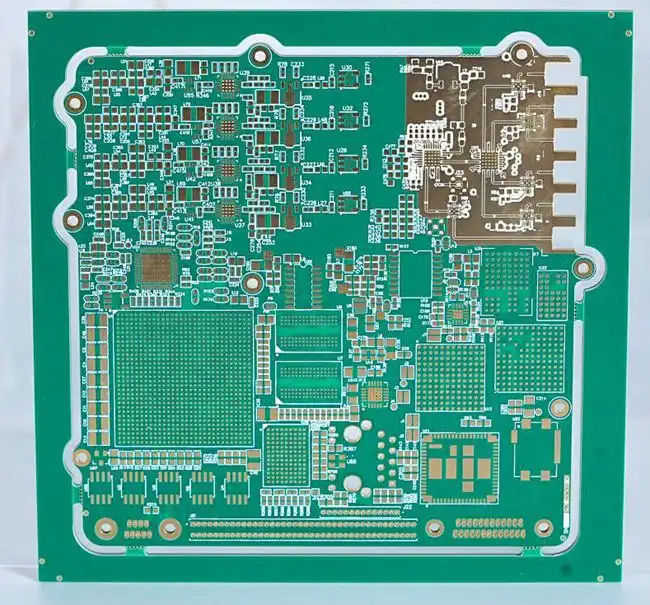

The complexity of your PCB plan and the number of layers essentially influence generation time. Straightforward 4-layer sheets can be fabricated generally rapidly, whereas more perplexing plans with 8, 10, or indeed 20+ layers require extra preparing steps, expanding lead times. High-density interconnect (HDI) sheets with microvias and buried/blind vias include assist complexity and time to the fabricating prepare. These progressed structures require exact laser penetrating, controlled-depth directing, and exceedingly precise layer arrangement, all of which request cutting-edge hardware and thorough prepare control.

Moreover, HDI manufacture regularly includes consecutive cover cycles, specialized materials, and more tightly resistances to accomplish the vital flag execution in high-speed applications. As a result, producers must keep up strict quality confirmation and ceaseless observing to guarantee unwavering quality, making HDI generation more resource-intensive but basic for cutting edge compact electronics.

Material Selection and Availability

The sort of substrate fabric utilized in your Multilayer PCB Manufacturing can affect lead times. Standard FR-4 materials are ordinarily promptly accessible, permitting for speedier turnaround. Be that as it may, specialized materials like high-frequency covers or metal-core PCBs may have longer acquirement times, influencing generally generation plans. Working with a producer that keeps up a assorted stock of materials can offer assistance moderate these delays.

By having basic substrates, components, and specialized covers promptly accessible, generation bottlenecks caused by supply deficiencies are altogether diminished. This guarantees that ventures remain on plan, indeed when startling request spikes or worldwide supply chain disturbances happen. Moreover, get to to a wide fabric determination permits for more prominent plan adaptability, speedier prototyping, and smoother scaling from little runs to full generation, eventually progressing generally productivity and unwavering quality in PCB manufacturing.

Production Volume and Batch Size

The amount of PCBs in your arrange plays a part in deciding lead times. Little model runs or low-volume generation can regularly be completed more rapidly, as they may be prioritized in the fabricating line. Bigger volume orders ordinarily require more broad setup and quality control forms, possibly amplifying lead times. Be that as it may, a few producers offer devoted high-volume generation lines that can keep up effectiveness indeed for huge bunches.

These specialized lines are optimized for nonstop operation, robotized gathering, and streamlined fabric taking care of, empowering steady quality, quicker turnaround times, and lower per-unit costs. This makes them perfect for assembly the requests of mass-market hardware and large-scale projects.

Optimizing Multilayer PCB Manufacturing Processes for Faster Turnaround

While certain factors affecting lead times are inherent to the complexity of multilayer PCB production, there are several strategies that both manufacturers and customers can employ to streamline the process and reduce overall turnaround times:

Advanced Manufacturing Technologies

Cutting-edge hardware and innovations play a significant part in speeding up Multilayer PCB Manufacturing. State-of-the-art laser penetrating machines, for occasion, can quickly make microvias and through-holes with remarkable accuracy, altogether lessening handling time for complex HDI sheets. Mechanized optical assessment (AOI) frameworks and X-ray assessment instruments empower speedier and more precise quality control, minimizing delays caused by manual reviews and adjust.

AOI frameworks can rapidly distinguish surface abandons, misaligned components, patching issues, and other unmistakable inconsistencies with tall exactness, whereas X-ray assessment permits for non-destructive examination of covered up joints, such as BGAs and buried vias. By joining these innovations into the generation handle, producers can capture abandons early, diminish scrap rates, and guarantee that each PCB meets strict execution and unwavering quality standards.

Efficient Design for Manufacturing (DFM)

Collaboration between PCB creators and producers amid the early stages of improvement can significantly affect lead times. By actualizing strong Plan for Fabricating (DFM) hones, potential generation issues can be recognized and settled some time recently the fabricating prepare starts. This proactive approach minimizes the require for time-consuming plan modifications and decreases the probability of fabricating blunders that seem delay generation.

By tending to potential issues early in the plan and prototyping stages, it streamlines workflow, improves by and large item unwavering quality, and guarantees smoother, quicker time-to-market for complex PCB projects.

Streamlined Supply Chain Management

Effective supply chain administration is basic for keeping up steady and quick multilayer PCB generation. Producers who have set up connections with dependable providers and keep up well-stocked inventories of commonly utilized materials can essentially decrease lead times. Moreover, actualizing just-in-time (JIT) stock frameworks and leveraging determining apparatuses can offer assistance expect fabric needs and anticipate generation delays due to component deficiencies.

By closely observing request designs, lead times, and provider execution, producers can optimize stock levels, decrease overabundance stock, and guarantee that basic components are accessible accurately when required. This approach not as it were minimizes capacity costs and squander but too improves generation adaptability, permitting PCB get together lines to react rapidly to changes in arrange volume or plan prerequisites without compromising quality or conveyance schedules.

Balancing Speed and Quality in Multilayer PCB Manufacturing

While diminishing lead times is frequently a need for numerous ventures, it's pivotal to keep up a adjust between speed and quality in multilayer PCB generation. Surging through basic fabricating steps can lead to absconds, unwavering quality issues, and exorbitant adjust. Here are a few contemplations for accomplishing this balance:

Comprehensive Quality Assurance Protocols

Implementing strong quality control measures all through the fabricating prepare is basic for guaranteeing that speedier generation doesn't come at the cost of unwavering quality. This incorporates in-line reviews, electrical testing, and last quality checks. Progressed testing strategies such as flying test testing, in-circuit testing (ICT), and useful testing can rapidly distinguish issues without essentially affecting in general lead times.

Flexible Manufacturing Capabilities

Multilayer PCB Manufacturing with differing generation capabilities can superior adjust to changing extend necessities and timelines. This adaptability permits for the optimization of generation forms based on the particular needs of each multilayer PCB arrange. For occasion, having committed lines for model, small-batch, and high-volume generation empowers productive asset allotment and speedier turnaround over diverse extend types.

Continuous Process Improvement

Manufacturers committed to ongoing process improvement can steadily reduce lead times while maintaining or even enhancing quality standards. This involves regular analysis of production data, investment in employee training, and the adoption of lean manufacturing principles. By continuously refining their processes, PCB manufacturers can incrementally improve efficiency and reduce turnaround times for multilayer PCB production.

Conclusion

Understanding the factors that influence lead times in multilayer PCB manufacturing is crucial for effective project planning and execution. By working closely with experienced PCB suppliers and manufacturers who leverage advanced technologies and efficient processes, you can optimize your production timelines without compromising on quality.

As the demand for complex, high-performance PCBs continues to grow, partnering with a reliable multilayer PCB manufacturer that offers comprehensive assembly, testing, and one-stop services becomes increasingly valuable. These partnerships enable you to navigate the challenges of modern electronics development with confidence, ensuring timely delivery of high-quality, engineered PCB solutions for your most demanding projects.

FAQ

What is the minimum order quantity for multilayer PCBs?

We offer flexible production options, including small batch runs with no minimum order quantity.

Do you provide turnkey PCBA services?

Yes, we offer comprehensive turnkey PCBA services, including component procurement, SMT assembly, and testing.

Can you handle high-density interconnect (HDI) PCB designs?

Absolutely. We specialize in manufacturing complex HDI multilayer PCBs with advanced features like microvias and buried/blind vias.

What type of quality assurance do you perform?

We employ rigorous quality control measures, including AOI, X-ray inspection, and various electrical testing methods to ensure the highest standards of reliability.

Experience the Ring PCB Advantage: Unmatched Quality and Efficiency

At Ring PCB, we leverage our self-owned factory and vertically integrated supply chain to deliver superior multilayer PCB manufacturing solutions. Our triple quality assurance process, including AOI, impedance testing, and thermal cycling, ensures a defect rate of less than 0.2%. With global certifications like ISO9001 and IATF16949, we guarantee top-tier PCB and PCBA services. Experience the difference of working with a true engineering partner. Contact us at [email protected] to discuss your next project.

References

1. Johnson, R. (2022). "Advancements in Multilayer PCB Manufacturing Techniques". Journal of Electronics Manufacturing, 15(3), 78-92.

2. Smith, A. et al. (2021). "Optimizing Lead Times in High-Complexity PCB Production". International Conference on Electronics Assembly, pp. 156-170.

3. Lee, S. and Park, J. (2023). "Impact of Material Selection on Multilayer PCB Manufacturing Efficiency". PCB Technology Review, 28(2), 45-59.

4. Brown, M. (2022). "Quality Assurance Protocols in Modern PCB Manufacturing". Electronics Production Quality, 17(4), 102-118.

5. Technical Committee on PCB Manufacturing. (2023). "Industry Standards for Multilayer PCB Production Lead Times". Global Electronics Manufacturing Association, Standard No. PCB-2023-01.