Key Factors in Evaluating PCB Assembly Services

When setting out on the travel to select the perfect PCB Gathering benefit supplier, it's pivotal to dive profound into different viewpoints that can essentially affect the quality, effectiveness, and cost-effectiveness of your extend. Let's investigate the fundamental components that merit your consideration amid this assessment process.

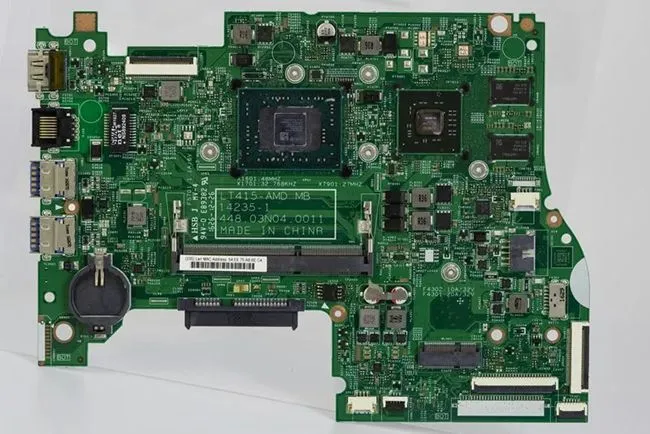

Technical Capabilities and Expertise

The foundation of any legitimate PCB Gathering benefit lies in its specialized ability. A provider's capacity to handle perplexing plans, execute progressed gathering methods, and explore complex forms is vital. See for companies that grandstand skill in high-density interconnect (HDI) PCBs, multilayer sheets, and specialized advances like flex and rigid-flex gatherings. Their capability in surface mount innovation (SMT), through-hole gathering, and mixed-technology sheets can be a confirmation to their versatility.

Moreover, consider their encounter with diverse businesses. A supplier serving aviation, car, or restorative segments might have rigid quality measures and progressed capabilities that might advantage your venture, in any case of your particular industry. Ask almost their plan for fabricating (DFM) and plan for get together (DFA) hones, as these can essentially upgrade item unwavering quality and diminish costs.

Quality Assurance and Certifications

Quality ought to never be compromised when it comes to PCB Assembly Services. A vigorous quality confirmation framework is demonstrative of a provider's commitment to fabulousness. See for companies that utilize progressed review procedures such as Computerized Optical Assessment (AOI), X-ray assessment, and In-Circuit Testing (ICT). These strategies guarantee that amassed PCBs meet the most elevated benchmarks of quality and reliability. Certifications play a vital part in approving a provider's adherence to industry measures.

ISO 9001 certification is a standard, but extra certifications like ISO 13485 for restorative gadgets, AS9100 for aviation, or IATF 16949 for car can give additional affirmation of their quality administration frameworks. Do not delay to inquire for point by point data approximately their quality control forms and how they handle non-conformities.

Production Capacity and Flexibility

The capacity to scale generation agreeing to your needs is a basic calculate in choosing a PCB Get together accomplice. Assess their generation capacity, counting the number and sorts of gathering lines they work. A supplier with different SMT lines and through-hole get together capabilities can offer more noteworthy adaptability and quicker turnaround times. Consider their approach to both model and volume generation. A few suppliers exceed expectations in fast prototyping with quick-turn capabilities, whereas others are adapted towards high-volume fabricating.

In a perfect world, you need a accomplice that can bolster your item all through its lifecycle, from starting prototyping to full-scale production. Flexibility in terms of arrange amounts is another significant perspective. A supplier that can oblige both little group runs and large-scale generation without compromising on quality or lead times can be priceless, particularly if your generation needs fluctuate.

Evaluating Cost-Effectiveness and Value-Added Services

While technical capabilities and quality assurance are paramount, the financial aspects and additional services offered by PCB Assembly providers can significantly influence your decision. Let's explore how to assess these factors to ensure you're getting the best value for your investment.

Pricing Structure and Transparency

Understanding a provider's estimating demonstrate is vital for precise budgeting and taken a toll comparison. See for straightforwardness in their citation prepare. A point by point breakdown of costs, counting PCB manufacture, component sourcing, gathering, testing, and any extra administrations, permits for a more exact comparison between providers.

Be watchful of costs that appear as well great to be genuine, as they might show compromises in quality or covered up costs. Instep, center on suppliers that offer competitive estimating whereas keeping up tall measures of quality and benefit. A few constructing agents might offer volume rebates or estimating levels, which can be invaluable if you expect scaling your generation in the future. Consider the add up to fetched of possession or maybe than fair the forthright cost.

Components like surrender rates, revamp costs, and the potential for plan optimization can essentially affect the by and large extend taken a toll. A supplier that offers plan for manufacturability (DFM) audits or component building administrations might offer assistance decrease costs in the long run by progressing item unwavering quality and lessening get together issues.

Component Sourcing and Supply Chain Management

The capacity to productively source and oversee components is a basic viewpoint of the PCB Assembly Services field. Assess suppliers based on their component sourcing capabilities, counting their connections with providers and their capacity to handle both common and specialized components. Look for constructing agents that offer charge of materials (BOM) optimization administrations. They can recommend elective components that might offer way better execution, accessibility, or cost-effectiveness.

This ability can be especially important in exploring component deficiencies or out of date quality issues. Consider suppliers that offer stock administration administrations, particularly if you're arranging for progressing generation. Their capacity to estimate request, keep up buffer stocks, and oversee just-in-time conveyance can offer assistance minimize your stock costs and decrease lead times.

Value-Added Services and Technical Support

The breadth of administrations advertised past fundamental get together can set suppliers separated. See for those that offer comprehensive arrangements, counting PCB plan administrations, prototyping, utilitarian testing, and indeed box construct get together. These coordinates administrations can streamline your advancement prepare and decrease the require for numerous vendors. Technical bolster and designing collaboration are important, particularly when managing with complex or imaginative plans.

Suppliers that offer plan audit administrations, warm investigation, flag astuteness recreations, or other progressed building back can contribute altogether to your product's success. Consider the level of extend administration and communication advertised. Suppliers with devoted extend directors, online following frameworks, and clear communication channels can significantly improve the productivity of your extend and give peace of intellect all through the gathering process.

Assessing Long-Term Partnership Potential

While immediate project needs are important, considering the potential for a long-term partnership can yield significant benefits. Let's explore the factors that indicate a PCB Assembly provider's suitability as a long-term collaborator in your product development and manufacturing journey.

Technological Advancement and Innovation

The gadgets industry is characterized by fast mechanical progressions. A forward-thinking PCB Gathering accomplice ought to illustrate a commitment to remaining at the cutting edge of innovation. Evaluate their speculation in advanced hardware, such as the most recent SMT arrangement machines, progressed review frameworks, and cutting-edge testing equipment. Inquire around their approach to rising advances like 5G, Web of Things (IoT), and counterfeit insights (AI) applications in gadgets.

Suppliers that effectively lock in in inquire about and advancement or collaborate with innovation accomplices are more likely to bolster your future item developments effectively. Consider their capabilities in progressed gathering strategies such as chip-on-board (COB), flip-chip, and wafer-level bundling. Indeed if you do not require these advances presently, a supplier with assorted capabilities can back your item advancement without the require to switch partners.

Scalability and Global Reach

As your commerce develops, your fabricating needs may advance, making it essential to choose PCB Assembly Services that can scale with your production demands and adapt to new technological requirements. Assess the provider's capacity to scale generation volumes and handle expanded complexity. This incorporates not as it were their generation capacity but moreover their capacity to oversee bigger supply chains and more complex logistics. For businesses with worldwide desire, consider the provider's topographical impression.

Do they have different fabricating areas or organizations that can back generation closer to your target markets? This can be vital for diminishing shipping costs and lead times, as well as exploring exchange regulations. Assess their involvement in worldwide coordinations and their capacity to handle worldwide shipping, traditions clearance, and compliance with different territorial measures. A accomplice with worldwide skill can be important as you grow into modern markets.

Financial Stability and Business Continuity

The money related wellbeing of your PCB Gathering accomplice is significant for guaranteeing a steady, long-term relationship. Whereas it might be challenging to get nitty gritty monetary data, see for pointers of monetary steadiness such as a long time in commerce, unfaltering development, and speculations in framework and technology. Inquire almost their commerce progression plans.

How do they handle disturbances in the supply chain or startling occasions? A supplier with strong hazard administration methodologies and reinforcement plans can offer more unwavering quality in the confront of worldwide uncertainties. Consider their track record with long-term clients. Case ponders or tributes from clients who have worked with the supplier over amplified periods can give experiences into their unwavering quality and capacity to advance with client needs.

Conclusion

Selecting the right PCB Assembly service provider is a critical decision that can significantly impact your product's quality, time-to-market, and overall success. By thoroughly evaluating technical capabilities, quality assurance practices, cost-effectiveness, value-added services, and long-term partnership potential, you can identify a supplier or manufacturer that aligns perfectly with your project requirements and business objectives.

Remember that the ideal partner goes beyond mere assembly services. Look for a provider that offers comprehensive solutions, from design optimization to final product testing. A collaborator that brings expertise in advanced technologies, supply chain management, and global manufacturing can be a valuable asset in navigating the complexities of modern electronics production.

Ultimately, the right PCB Assembly partner should feel like an extension of your own team, committed to your product's success and capable of supporting your growth and innovation for years to come. Take the time to conduct thorough evaluations, request samples, and engage in detailed discussions before making your decision. The effort invested in this process will pay dividends in the form of high-quality products, streamlined production, and a competitive edge in your market.

FAQ

What is the typical turnaround time for PCB Assembly services?

Turnaround times can vary widely depending on the complexity of the project and the provider's capabilities. For simple prototypes, some assemblers offer quick-turn services as fast as 24-48 hours. More complex or high-volume projects may take several weeks.

How important are certifications when choosing a PCB Assembly provider?

Certifications are crucial as they validate a provider's adherence to industry standards. ISO 9001 is a baseline, while certifications like ISO 13485, AS9100, or IATF 16949 indicate expertise in specific industries.

Can PCB Assembly providers help with component sourcing?

Many providers offer component sourcing as part of their services. They can often leverage industry relationships to source components more efficiently and may offer BOM optimization to suggest cost-effective alternatives.

Integrated PCBA Solutions: Full-Service Excellence | Ring PCB

At Ring PCB, we offer comprehensive PCBA solutions that go beyond assembly. Our services encompass PCB fabrication, component sourcing, SMT assembly, and rigorous functional testing. Our expert engineering team specializes in DFM/DFA optimization, reducing design risks and BOM costs. With state-of-the-art X-ray inspection, AOI testing, and 100% functional validation, we ensure zero-defect delivery.

As a leading PCB manufacturer and supplier, we're committed to delivering high-quality, cost-effective solutions. Contact us at [email protected] to experience our factory's excellence in PCBA services.

References

1. Smith, J. (2022). "Comprehensive Guide to PCB Assembly Service Evaluation." Electronics Manufacturing Today, 18(3), 45-52.

2. Johnson, R., & Thompson, L. (2021). "Quality Assurance in PCB Assembly: A Comparative Study of Industry Standards." Journal of Electronics Manufacturing, 29(2), 112-125.

3. Lee, S. (2023). "The Impact of Advanced Technologies on PCB Assembly Services." International Journal of Electronics Production, 41(4), 301-315.

4. Chen, Y., & Davis, M. (2022). "Cost-Effective Strategies in PCB Assembly: A Global Perspective." Supply Chain Management in Electronics, 15(1), 78-92.

5. Wilson, K. (2023). "Long-Term Partnerships in Electronics Manufacturing: Key Factors for Success." Business Strategy Review, 37(2), 205-218.