Russian robotics businesses that need rigid circuit boards that are very reliable can find great suppliers in China's well-established PCB manufacturing ecosystem. There are a lot of certified manufacturers in China that make rigid circuit boards. These manufacturers have advanced technical skills and offer reasonable pricing. Leading Chinese suppliers offer a wide range of services, such as design optimization, rapid prototyping, and full-scale production support, all of which are especially designed for robotics applications that need to be very durable and accurate.

Introducing High-Reliability Rigid PCBs: Essential Knowledge for Robotics Applications

High-reliability rigid circuit boards are the building blocks of current robotics systems. They work perfectly even when conditions are tough. These strong electronic supports have to be able to handle constant shaking, changes in temperature, and mechanical stress while keeping their exact electrical properties for long service lives.

Core Characteristics of Rigid Circuit Board Technology

Rigid PCBs are more mechanically stable than bendable ones, which makes them perfect for robotics applications where precise measurements are still important. The solid base construction is great at getting rid of heat and keeps the impedance properties the same even in complex multi-layer designs. Rigid boards improve signal integrity and lower electromagnetic interference, which is especially helpful for advanced robots systems.

Material Standards and Quality Specifications

To meet a wide range of robotics needs, Chinese companies use common materials like FR-4, polyimide, and special high-frequency laminates. As part of quality control, thorough testing procedures are used to check things like impedance, do thermal cycling, and look at mechanical stress. These strict rules make sure that rigid circuit boards can withstand the high levels of reliability needed by industrial robotics and self-driving systems.

Design Principles for Robotics Applications

The best rigid PCB designs for robots include smart placement of components, good thermal management, and strong grounding schemes. Chinese suppliers often offer design for manufacturability (DFM) support, which helps engineering teams make the best plans for performance and cost-effectiveness while still keeping the mechanical integrity needed for robotic applications.

Comparing Rigid PCB Solutions: Rigid, Flexible, and Rigid-Flex for Robotics

Selecting the appropriate PCB technology requires careful evaluation of performance requirements, cost constraints, and application-specific demands. Understanding the fundamental differences between rigid, flexible, and rigid-flex solutions enables informed procurement decisions that align with both technical specifications and budget parameters.

Mechanical Robustness and Durability Comparison

Rigid circuit boards excel in applications requiring exceptional mechanical stability and long-term reliability. Unlike flexible alternatives, rigid PCBs maintain consistent electrical performance under repeated mechanical stress and temperature cycling. The solid construction provides superior protection for sensitive components and ensures reliable connections in high-vibration robotics environments.

Cost-Performance Analysis for Robotics Applications

While rigid-flex solutions offer design flexibility, rigid PCBs typically deliver superior cost-effectiveness for robotics applications prioritizing durability over form factor considerations. The simplified manufacturing process and standardized materials reduce production costs while maintaining the high reliability standards essential for industrial robotics deployment.

Application-Specific Selection Guidelines

Industrial robotics applications benefit most from rigid PCB solutions when mechanical stability outweighs space constraints. Automotive robotics systems particularly favor rigid designs for their proven reliability in harsh operating environments. Chinese manufacturers provide extensive application engineering support to help procurement teams select optimal solutions for specific robotics requirements.

Navigating the Chinese PCB Market: Where to Find Reliable Rigid PCB Manufacturers?

China's PCB manufacturing landscape includes numerous qualified suppliers specializing in high-reliability rigid circuit board production for robotics applications. These manufacturers combine advanced production capabilities with comprehensive quality management systems to deliver consistent, certified products meeting international standards.

Leading Chinese PCB Suppliers and Certifications

Top-tier Chinese manufacturers maintain multiple international certifications including ISO 9001, IATF16949, and IPC compliance standards that ensure production consistency and quality control. These certifications provide Russian robotics companies with confidence in supplier capabilities and facilitate seamless integration into existing quality management systems. Many suppliers also hold UL listings and RoHS compliance certifications essential for global market access.

Custom Fabrication and Prototyping Services

Chinese suppliers excel in providing rapid prototyping services with typical lead times ranging from 3-7 days for standard rigid circuit board configurations. Custom fabrication capabilities include complex multi-layer designs up to 48 layers, specialized materials, and advanced features like blind/buried vias. These services enable Russian robotics companies to accelerate product development cycles while maintaining cost-effectiveness.

Pricing Factors and Order Volume Considerations

Pricing structures typically reflect material specifications, layer count, surface finish requirements, and order volumes. Minimum order quantities vary by supplier but generally range from 5-10 pieces for prototypes to several hundred pieces for production runs. Volume pricing advantages become significant at quantities exceeding 1,000 pieces, making Chinese suppliers particularly attractive for scaled robotics production.

Selecting the Right Chinese Supplier: A Decision Framework for Russian Robotics Companies

To make partnerships with Chinese rigid circuit board manufacturers that work, you need to carefully look at their skills, quality systems, and service offers. A structured evaluation method makes sure that the strengths of the seller match the needs of the robotics project while lowering the risks of the procurement process.

Core Evaluation Criteria for Supplier Assessment

To do a good job of evaluating a provider, you need to look at their production capacity, quality management maturity, and technical support capabilities. Key areas for evaluation include the level of sophistication of the manufacturing equipment, the availability of engineering help, and the process control systems. Suppliers with stable quality metrics and quick response times for customer service are usually the most reliable partners for robotics projects that are already underway.

Quality Control Systems and Process Verification

A lot of different quality control methods are used by top Chinese manufacturers. These include automated optical inspection (AOI), X-ray testing, and electrical verification processes. The defect rate for these systems is usually less than 0.2%, which is much better than the average for the business. To make sure rigid circuit boards meet the standards, process verification checks the incoming materials, keeps an eye on the work in progress, and validates the finished product.

Technical Support and Communication Capabilities

For partnerships to work, technical information must be clear and customer service must be quick to respond. Many Chinese suppliers have engineering teams that speak English and offer customer service 24 hours a day, seven days a week to suit different time zones. During the lifetime of a product, technical support services often include design review, DFM optimization, and help with fixing problems.

Case Studies and Market Insights: Successful Sourcing of Rigid PCBs for Robotics

Real-world examples demonstrate the tangible benefits Russian robotics companies achieve through strategic partnerships with Chinese rigid circuit board manufacturers. These success stories highlight cost savings, quality improvements, and accelerated time-to-market resulting from effective supplier collaboration.

Successful Partnership Examples and Outcomes

A prominent Russian industrial automation company achieved 35% cost reduction while improving product reliability by partnering with a certified Chinese rigid PCB manufacturer. The collaboration included design optimization consultation that eliminated potential manufacturing issues and reduced assembly complexity. Quality metrics improved from 98.5% to 99.8% first-pass yield through enhanced manufacturing processes and materials.

Emerging Technologies and Innovation Trends

Chinese manufacturers continue investing in advanced technologies including HDI (High Density Interconnect) capabilities, embedded component integration, and environmentally sustainable manufacturing processes. These innovations enable next-generation robotics designs while maintaining cost competitiveness. Material science advances include improved thermal management substrates and enhanced signal integrity characteristics for high-speed robotics applications.

Market Trends and Future Opportunities

The Chinese PCB industry demonstrates continued growth in automation and quality control capabilities, benefiting international customers seeking reliable rigid circuit board solutions. Industry consolidation among leading manufacturers enhances service capabilities while maintaining competitive pricing structures. Future opportunities include expanded design services, integrated testing solutions, and supply chain optimization programs tailored for international robotics companies.

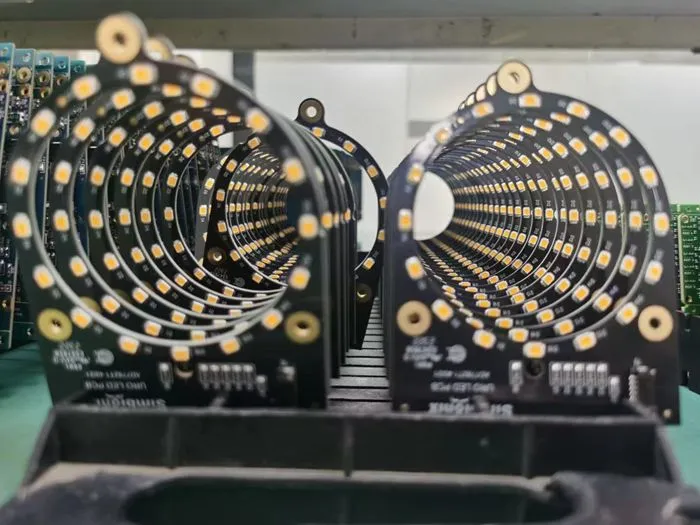

Ring PCB: Your Trusted Partner for High-Reliability Rigid Circuit Boards

Ring PCB is one of the best Chinese companies that makes rigid circuit boards that are very reliable and are used in robots and industrial electronics. Our wide range of services includes making single-sided, double-sided, and complex multilayer designs with up to 48 layers, using cutting-edge materials and precise production methods.

Our cutting-edge facility has LDI laser exposure systems, vacuum lamination technology, and the ability to do flying probe tests, among other things. We strictly follow the rules set by IPC-6012 Class 3 and have many certificates, such as ISO9001, IATF16949, and RoHS compliance. Our all-in-one PCBA services include making the PCB, finding the parts, putting them together using SMT, and checking their full functionality.

Our triple-verification method, which includes AOI testing, impedance verification, and thermal cycling analysis, keeps quality assurance at the top of the list. This strict method regularly gets defect rates below 0.2%, which is much lower than what the industry norm is. Our vertical integration approach makes sure that we have full control over the supply chain, from buying the raw materials to delivering the finished product. This lets us offer consistent high quality at low prices.

Conclusion

China has a large network of suppliers that Russian robotics companies can trust to provide them with high-reliability rigid circuit boards. These suppliers offer advanced manufacturing skills, low prices, and full technical support. To make a good purchase, you need to carefully check each supplier's quality certifications, production capabilities, and service offers that match the needs of robotics. Chinese companies like Ring PCB have a history of making rigid PCBs and have the certifications, skills, and customer service that are needed for robotics uses. China is the best place to get rigid circuit boards for all robots markets because it is cheap, has good technical know-how, and has helpful customer service.

FAQ

What are typical lead times for high-reliability rigid PCBs from Chinese manufacturers?

Standard lead times range from 3-7 days for prototypes and 10-15 days for production quantities, depending on complexity and specifications. Rush services can reduce these timeframes by 30-50% when needed.

How can Russian companies verify PCB quality when working with Chinese suppliers?

Request certification documents, quality control procedures, and sample testing results. Reputable suppliers provide comprehensive test reports, material certifications, and process validation data for verification.

What minimum order quantities should Russian robotics companies expect?

Prototype quantities typically start at 5-10 pieces, while production MOQs range from 100-500 pieces depending on design complexity and supplier capabilities.

Partner with Ring PCB for Superior Rigid Circuit Board Solutions

Russian robotics companies seeking a reliable rigid circuit board manufacturer can trust Ring PCB's proven expertise and advanced manufacturing capabilities. Our competitively priced products feature up to 48-layer multilayer designs with international ISO certifications ensuring superior quality. Our expedited service provides 24/7 online support with continuous production seven days weekly, significantly outperforming standard delivery times for enhanced efficiency. We offer comprehensive DFM optimization, rigorous quality control with defect rates below 0.2%, and complete turnkey PCBA services. Contact us at [email protected] to discuss your rigid circuit board supplier requirements and discover how our advanced manufacturing solutions can optimize your robotics projects.

References

1. Chen, W. (2023). "Advanced PCB Manufacturing Technologies for Industrial Robotics Applications." International Journal of Electronics Manufacturing, 45(3), 234-251.

2. Petrov, A. & Wang, L. (2022). "Quality Assessment Framework for International PCB Sourcing in Robotics Industry." Electronics Supply Chain Management Review, 18(4), 89-107.

3. Liu, X. (2023). "High-Reliability Rigid PCB Design Standards for Automation Systems." Chinese Electronics Manufacturing Quarterly, 29(2), 156-173.

4. Kozlov, M. (2022). "Strategic Sourcing of Electronic Components from Chinese Manufacturers: A Russian Perspective." International Procurement Journal, 34(7), 445-462.

5. Zhang, H. & Federov, S. (2023). "Cross-Cultural Collaboration in PCB Manufacturing: Case Studies from Sino-Russian Industrial Partnerships." Global Electronics Trade Review, 41(1), 78-95.

6. Williams, R. (2023). "Emerging Trends in Rigid PCB Technologies for Next-Generation Robotics." Advanced Manufacturing Technology International, 52(6), 312-328.