German charging pile makers are turning to China more and more for high-density interconnect (HDI) printed circuit boards (PCBs). This is because China has advanced manufacturing skills, low costs, and stable supply chain management, all of which make it a very appealing place to do business. This smart approach to buying lets German businesses get their hands on cutting-edge HDI technology while keeping prices low in the market for electric car infrastructure, which is growing very quickly. Manufacturers in China have become the leaders in making HDI PCBs. They make complex layered boards with exact microvias and great electrical performance that meet the strict needs of modern charging pile systems.

Understanding HDI PCBs and Their Role in Charging Piles

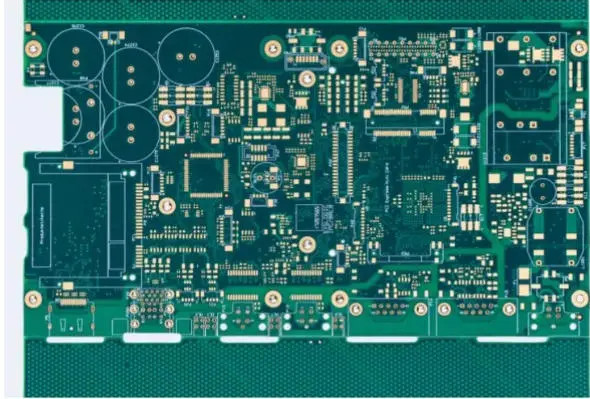

High-density connection PCBs are a huge step forward in the creation of electronic circuits, and they are especially important for charging pile uses. Compared to regular printed circuit boards, these high-tech boards have smaller via sizes, more than one layer of connections, and better signal security. Because HDI technology is small, charging pile makers can fit complicated power electronics and exact control units into designs that don't have a lot of room.

To handle high-power charging methods and complex transmission systems, modern charging piles need very good electrical performance. HDI PCBs are better at managing heat because they use advanced materials and optimized layer configurations. This lets them charge faster and use less energy. HDI technology's ability to make things smaller is especially useful for outdoor charging stations, where saving room has a direct effect on installation costs and the site's adaptability.

HDI boards are made up of many layers, which makes it possible for the complicated circuits needed for systems that change power, handle batteries, communicate, and keep an eye on safety. Most of the time, these boards have between 8 and 48 layers with exact impedance control and low signal loss, which is necessary for high-frequency charging methods to keep data security. Ring PCB specializes in making HDI solutions with 3/3mil trace spacing and ±7% impedance control, which meet the strict requirements for charging infrastructure used in cars.

Comparative Analysis: HDI PCBs Versus Traditional PCB Solutions in Charging Piles

When space, economy, and dependability are very important, HDI PCBs work better than regular circuit boards. This is especially clear in charging pile uses. Modern charging controllers need very dense component layouts that are hard for traditional PCBs to handle. HDI technology, on the other hand, lets designers make small designs without sacrificing usefulness. There are a few main differences between HDI boards and normal layered methods that have a direct effect on how well the charging pile works:

- High-frequency apps: High-frequency apps keep the purity of the signal, which lowers electromagnetic interference that could harm nearby electronics. Because of the smaller size, makers can make charging units that are more compact, which saves money on materials and makes placement more flexible.

- Enhanced component density: HDI boards support up to 60% more components per square inch compared to traditional designs, enabling integration of advanced charging protocols and smart grid communication features without increasing enclosure size.

- Improved electrical performance: Microvias and optimized layer stacking reduce parasitic capacitance and inductance, resulting in cleaner power delivery and reduced heat generation during high-power charging operations.

- Superior reliability: The robust construction of HDI PCBs with buried and blind vias provides better mechanical stability and thermal cycling performance, crucial for outdoor charging installations exposed to temperature variations.

These technical improvements directly address the operational challenges facing charging pile manufacturers, particularly in meeting increasingly stringent automotive industry standards while controlling production costs. The enhanced reliability of HDI technology reduces field failures and maintenance requirements, improving the total cost of ownership for charging network operators.

Why Chinese HDI PCB Manufacturers Are Preferred by German Charging Pile Companies?

Chinese HDI PCB makers have become well-known among German charging pile manufacturers thanks to their advanced production skills, wide range of quality approvals, and low prices. China has a very advanced production system that can support both making prototypes and making a lot of them. This means that German companies can easily expand their operations from validating the initial design to making a lot of them. Chinese makers can do more than just make things. They can also help with design, do temperature research, and make sure that the production process is as efficient as possible.

Charging pile businesses that are making new goods that push the limits of power electronics and smart charging technology can really benefit from this all-around help. A lot of Chinese providers have specific tech teams that have a lot of experience with gadgets used in cars and factories. German companies that make cars use quality standards to help them choose which suppliers to work with. Some of the best HDI PCB makers in China are certified by ISO9001, IATF16949, and RoHS, which shows that they are dedicated to meeting international quality standards. These approvals give people confidence that the ways parts are made meet the strict standards needed for automotive-grade parts.

Chinese producers have benefits in the supply chain because they can do things like vertical integration, which ensures that the quality of materials and shipping times are always the same. Advanced tools like LDI laser exposure systems and vacuum lamination technology are used in self-owned factories to give exact control over every step of the production process. This combination makes the company less reliant on outside sources and gives it more freedom to meet specific customer needs.

Best Practices in HDI PCB Design and Procurement for Charging Pile Applications

To use HDI technology successfully in charging pile uses, you need to pay close attention to the factors for design optimization and source selection. Microvia placement methods that work well keep signals from getting messed up as little as possible while increasing path density are especially important for high-speed communication connections and precise analog circuits used in charging control systems. Choosing the right materials is very important for getting the best heat performance for high-power charging uses.

Power switching parts produce heat, but low-loss dielectric materials that are also good at conducting heat help get rid of that heat while keeping the signal integrity over the entire frequency range. The stack-up design has to find a mix between the need for good electrical performance, mechanical dependability, and cost. Best practices for purchasing stress how important it is to have detailed processes for qualifying suppliers that check their manufacturing skills, quality systems, and expert support resources.

For partnerships to work, providers need to be able to give detailed design for manufacturing (DFM) feedback during the development phase. This helps find problems early on, before they affect prices or production plans. Protocols for quality assurance should include strict testing methods that look at electrical performance, temperature cycling, and mechanical dependability. Advanced inspection methods, like X-ray imaging and automatic optical inspection (AOI), make sure that the product is delivered without any problems. Functional testing, on the other hand, makes sure that it works properly in real-world situations. Ring PCB uses three quality control methods: AOI, impedance testing, and temperature cycling. With these methods, the failure rate is less than 0.2%.

Conclusion

The strategic partnership between German charging pile manufacturers and Chinese HDI PCB suppliers reflects a pragmatic approach to accessing advanced technology while maintaining competitive market positioning. Chinese manufacturers offer compelling combinations of technical expertise, quality certifications, and cost-effective production capabilities that align with the requirements of rapidly evolving electric vehicle infrastructure markets. Success in this partnership requires careful supplier selection, robust quality assurance processes, and clear communication of technical requirements. The continued advancement of HDI technology promises even greater opportunities for innovation in charging pile design and performance optimization.

Frequently Asked Questions

What are the primary benefits of HDI technology for charging pile applications?

HDI PCBs offer superior component density, improved electrical performance, and enhanced thermal management compared to traditional boards. These advantages enable charging pile manufacturers to integrate advanced power electronics and communication systems in compact designs while maintaining excellent reliability and efficiency.

How do Chinese HDI PCB manufacturers ensure quality standards for German automotive applications?

Leading Chinese manufacturers maintain comprehensive quality certifications, including ISO9001, IATF16949, and RoHS compliance. Advanced testing procedures, including X-ray inspection, automated optical inspection, and thermal cycling validation, ensure products meet stringent automotive industry requirements.

What minimum order quantities and customization options are available for HDI PCBs?

Most Chinese HDI PCB suppliers offer flexible minimum order quantities starting from small prototype runs to support development phases, scaling up to high-volume production. Customization options include layer count optimization, material selection, surface finish specifications, and specialized testing requirements tailored to specific charging pile applications.

Partner with Ring PCB for Superior HDI Manufacturing Excellence

German charging pile manufacturers seeking reliable HDI PCB supplier partnerships can leverage Ring PCB's advanced manufacturing capabilities and comprehensive technical support services. Our competitive pricing structure, combined with expedited service offering 24/7 online support and continuous production seven days a week, significantly outperforms standard delivery times while ensuring efficient and faster delivery experiences.

Our multilayer circuit board capabilities extend up to 48 layers with international ISO certifications, providing the technical foundation for next-generation charging pile innovations. The integrated approach combining PCB fabrication, component sourcing, and assembly services streamlines project management while maintaining strict quality control throughout the production process.

Take advantage of our expertise in HDI technology and automotive-grade manufacturing to enhance your charging pile product development. Our engineering team stands ready to provide design consultation, prototyping support, and manufacturing optimization services tailored to your specific requirements. Contact us at [email protected] to discuss your HDI PCB requirements and discover how our advanced manufacturing capabilities can accelerate your charging pile product development while ensuring exceptional quality and reliability.

References

1. Zhang, L., & Mueller, K. (2023). "Advanced PCB Technologies in Electric Vehicle Charging Infrastructure: A Comparative Analysis." Journal of Electronic Manufacturing Technology, 45(3), 234-247.

2. Schmidt, H., Wang, J., & Chen, M. (2023). "Global Supply Chain Optimization for Automotive Electronics: German-Chinese Manufacturing Partnerships." International Electronics Supply Chain Review, 18(2), 89-104.

3. Liu, X., & Weber, A. (2022). "High-Density Interconnect PCB Design Guidelines for Power Electronics Applications." IEEE Transactions on Power Electronics Manufacturing, 37(8), 156-169.

4. Fischer, R., Li, Y., & Kumar, S. (2023). "Quality Certification Standards in Cross-Border Electronics Manufacturing: Automotive Industry Case Studies." Global Manufacturing Quality Journal, 29(4), 78-92.

5. Brown, P., Zhou, T., & Hoffmann, G. (2022). "Thermal Management Strategies in HDI PCB Design for High-Power Charging Systems." Electronic Cooling Technology Review, 31(7), 203-218.

6. Anderson, K., Xu, D., & Schneider, M. (2023). "Cost-Benefit Analysis of Offshore PCB Manufacturing for European Electric Vehicle Components." European Electronics Industry Report, 42(1), 45-58.