More and more, Russian importers are turning to Chinese manufacturers for Industrial Grade PCBA solutions because China has a great mix of low prices, technical know-how, and stable supply chain management. China's PCBA makers have become reliable partners by consistently delivering high-quality industrial-grade printed circuit board assemblies that meet strict international standards. They also keep their prices low, which helps purchasing managers in many fields, such as medical devices, communication equipment, and automotive electronics.

Understanding Industrial-Grade PCBA: Specifications & Benefits

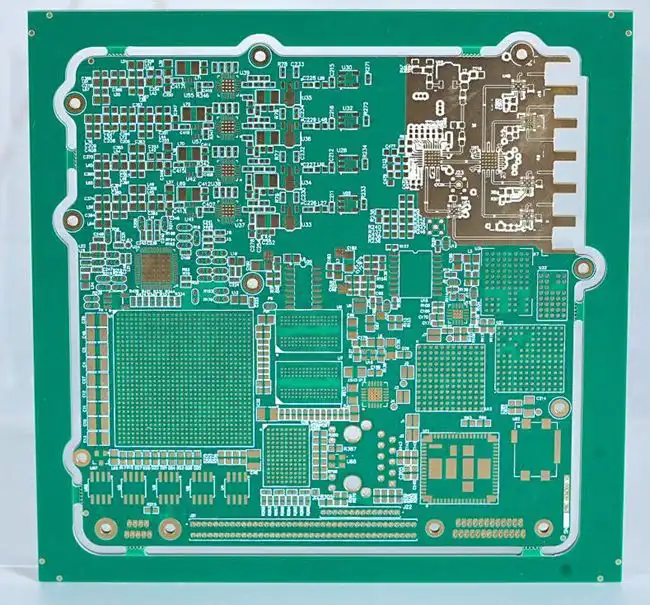

When it comes to making electronics, industrial-grade printed circuit board assemblies are the most precise. They are designed to work in harsh conditions where regular consumer electronics would not work. Extreme temperature changes, strong vibrations, electromagnetic interference, and long working cycles must not affect the performance or dependability of these specialized assemblies.

Technical Specifications That Define Industrial Standards

When it comes to strict technical requirements, consumer-grade parts are different from industrial-grade assemblies. Temperature ranges for industrial PCBAs are usually quite wide, spanning from -40°C to +85°C. For some specific uses, even wider ranges are needed, spanning from -55°C to +125°C. Advanced materials like polyimide substrates, high-temperature solder alloys, and conformal coatings are used in these systems to protect them better from moisture, chemicals, and mechanical stress.

Manufacturing standards are very important for setting quality levels in the business world. To get IPC Class 3 certification, which is the highest level of reliability, there must be no defects and thorough testing procedures that make sure the product will work for a long time in mission-critical applications. At this level of certification, manufacturers must use high-tech quality control methods like automated optical inspection, X-ray analysis, and functional testing processes that check the integrity of every part of the assembly.

Industry Applications and Performance Requirements

Russia's industrial sectors need Industrial Grade PCBA that can work efficiently in tough working conditions. For uses in the energy sector, units need to be able to handle high voltage and electromagnetic interference while still performing their precise control functions. For transportation systems to work, PCBAs need to be able to handle regular vibrations, changing temperatures, and being exposed to different environmental contaminants without losing their signal integrity or processing power.

Biocompatibility, sterilization resistance, and fail-safe operation procedures are all more important for medical devices. These assemblies must keep working the same way for long periods of time while also meeting strict regulatory compliance standards that govern the making and use of medical tools.

Why China Leads as a Supplier for Industrial-Grade PCBA in Russia?

Russia's buyers now prefer to buy from China because of its superior manufacturing, advanced technology, and efficient supply chain, which is hard to find in other places. Chinese manufacturers have put a lot of money into modern factories, advanced automation systems, and quality management programs that make sure they always give industrial-grade assemblies that meet international standards.

Manufacturing Capabilities and Quality Standards

It is possible for Chinese Industrial Grade PCBA makers to handle complicated multi-layer designs with precise trace routing, controlled impedance specifications, and cutting-edge packaging technologies because they have advanced manufacturing skills. Laser direct imaging systems, vacuum lamination processes, and flying probe testing tools are used in modern factories to make sure that all production runs are the same in terms of size and electrical performance.

Leading Chinese companies often go above and beyond what customers expect from their quality management systems. They do this by utilizing thorough certification programs such as ISO9001, IATF16949, and RoHS compliance verification. These certificates show that the company is dedicated to improving all the time and following the world quality standards that Russian buyers need for their industrial uses.

Cost Efficiency and Supply Chain Advantages

Chinese makers can offer lower prices because they use resources more efficiently, take advantage of economies of scale, and streamline their production processes. They don't lower quality standards to do this. Modern automation technologies allow regular production output while reducing the number of manual tasks that need to be done, which could cause variations or mistakes in the manufacturing process.

Integration of the supply chain has extra benefits because it makes it easier to find parts, keep track of inventory, and organize logistics. This cuts down on lead times and makes sure that materials are available for both prototype development and large-scale production. This connection feature is especially helpful for Russian importers who have to deal with tight budgets and complicated project schedules.

Key Considerations for Russian Importers When Procuring Industrial-Grade PCBA from China?

To successfully purchase industrial-grade assemblies, you need to carefully evaluate possible suppliers based on a number of factors that go beyond just price. When Russian buyers choose Chinese PCBA suppliers for important industrial uses, they need to look at how well they can make things, their quality control systems, their technical support services, and the chance of forming a long-term partnership.

Supplier Evaluation and Certification Requirements

Checking the supplier's manufacturing certifications, production capacity, and quality management system audits to make sure they can meet the needs of the project is the first step in a thorough review. When importing, companies should ask for thorough tours of the facility, reviews of the quality paperwork, and customer testimonials that show the product has worked well in similar industrial settings.

When you do a technical capability assessment, you need to look at things like design for manufacturing support, component sourcing knowledge, and the creation of testing protocols that make sure the assembly works well and is reliable. Suppliers should show that they can handle complicated multi-layer designs, precise component placement, and the unique packaging needs of industrial-grade uses.

Risk Mitigation and Quality Assurance Protocols

Clear quality specifications, thorough testing methods, and backup plans for dealing with possible supply chain problems or quality issues are all important parts of effective risk mitigation strategies. For Russian importers, it's important to make sure that quality agreements are very specific. These agreements should include acceptance criteria, testing methods, and ways to fix products that don't meet standards.

Protocols for communication and project management tools are very important for keeping things clear during the whole manufacturing process. Regular reports on progress, quality, and technology issues help find problems early in the production process, when they can be fixed without having a big effect on costs or schedule.

Case Studies: Successful Russian Importer Partnerships with Chinese Industrial PCBA Manufacturers

Real-world examples demonstrate the tangible benefits that Russian companies have achieved through strategic partnerships with Chinese Industrial Grade PCBA suppliers. These case studies highlight cost savings, quality improvements, and operational efficiencies that result from well-managed supplier relationships and effective procurement strategies.

Energy Sector Success Story

A large Russian company that makes energy equipment teamed up with a Chinese PCBA supplier to make control units for drilling platforms that are out at sea. Together, they were able to cut costs by 35% compared to European options while still meeting IPC Class 3 quality standards and the IP67 ratings needed for harsh marine settings. The Chinese supplier offered full design for manufacturing support that helped choose the best components, handle heat better, and improve electromagnetic compatibility. This technical cooperation cut the time it took to develop by six months and got rid of three rounds of design changes that would have added to the cost of the project and slowed down its release to the market.

Medical Device Manufacturing Partnership

A Chinese business that makes biocompatible parts for diagnostic equipment and a Russian company that makes medical devices have agreed to work together for a long time. The partnership sped up the process of making prototypes, getting governmental approvals, and successfully expanding the market into several European countries. Strict quality documentation, thorough testing methods, and ongoing improvement programs that raised product reliability and cut costs by 28% over the course of a three-year partnership were key to success. During the product creation and commercialization process, the supplier's ability to adapt to changes in design and new rules was very helpful.

Enterprise Introduction and Product & Service Information

Ring PCB brings extensive expertise in manufacturing premium industrial-grade PCBA solutions tailored specifically for demanding applications across multiple industrial sectors. Our advanced manufacturing facility features state-of-the-art equipment ,including LDI laser exposure systems, vacuum lamination technology, and comprehensive flying probe testing capabilities that ensure exceptional quality and reliability for every assembly we produce.

Advanced Manufacturing Capabilities

We can make very precise products with up to 48 layers of complicated designs that include blind and buried vias, trace and spacing specifications of 3/3mil, and impedance control accuracy of ±7%. Because of these skills, we can help with complex apps that need high performance and dependability, like 5G communications, industrial automation, medical diagnostics, and automotive electronics. IPC-6012 Class 3 standards are followed by comprehensive quality management practices that are part of smart manufacturing processes. Our self-owned factory has full control over the whole production process, from getting the raw materials to checking and packaging them at the end.

Comprehensive PCBA Services

Ring PCB provides full packaged solutions that make buying things easier and simplify the supply chain for our customers. We offer integrated services that include making PCBs, finding parts, putting them together using SMT, and checking their functionality. All of these tasks are done under one roof to ensure consistent quality and on-time delivery. Our experienced engineering team offers DFM and DFA optimization services that help find possible design problems early on in the development process. This lowers the cost of production and raises the reliability of the assembly. This proactive method keeps clients from having to pay for expensive design changes and speeds up the time it takes to bring new products to market.

Conclusion

Russian importers trust Chinese manufacturers for Industrial Grade PCBA solutions because of proven capabilities in delivering high-quality assemblies that meet rigorous industrial standards while providing significant cost advantages and supply chain efficiencies. Successful partnerships require careful supplier evaluation, comprehensive quality management protocols, and ongoing collaboration that ensures long-term success for both parties. Chinese manufacturers like Ring PCB have demonstrated their ability to support complex industrial applications through advanced manufacturing capabilities, stringent quality control systems, and responsive technical support services that address the evolving needs of global procurement professionals.

Frequently Asked Questions

What certifications should I look for when selecting a Chinese Industrial Grade PCBA manufacturer?

Essential certifications include ISO9001 for quality management, IATF16949 for automotive applications, IPC-6012 Class 3 for high-reliability assemblies, and RoHS compliance for environmental regulations. Additionally, look for UL certification for safety-critical applications and specific industry certifications relevant to your target market such as medical device regulations or telecommunications standards.

How can I verify the quality of Industrial Grade PCBA samples before placing volume orders?

Request comprehensive test reports including electrical testing, thermal cycling results, vibration testing data, and accelerated aging studies that demonstrate long-term reliability. Conduct independent third-party testing if necessary and request facility audits to verify manufacturing capabilities and quality control processes.

What are typical lead times and minimum order quantities for industrial-grade assemblies?

Lead times typically range from 2-4 weeks for standard configurations and 4-8 weeks for complex multi-layer designs with specialized components. Minimum order quantities vary based on complexity but generally range from 100-500 pieces for prototypes and 1000-5000 pieces for production orders, though some suppliers offer more flexible MOQ terms for established customers.

Partner with Ring PCB for Superior Industrial Grade PCBA Solutions

Ring PCB stands ready to support your industrial PCBA requirements with competitively priced solutions backed by our advanced 48-layer multilayer circuit board capabilities and comprehensive international ISO certifications. Our expedited service provides 24/7 online support and continuous production 7 days a week, significantly outperforming standard delivery times to ensure a more efficient and faster delivery experience for your projects.

As a trusted Industrial Grade PCBA manufacturer, we combine advanced engineering expertise with rigorous quality control processes that include triple quality assurance through AOI, impedance testing, and thermal cycling validation. Our defect rate remains below 0.2%, well under the industry average of 1%, demonstrating our commitment to zero-defect delivery standards.

Russian procurement managers, engineering teams, and supply chain professionals are invited to experience our comprehensive capabilities through sample evaluation programs and personalized consultation services. Contact us at [email protected] to discuss your specific requirements and discover how our industrial-grade PCBA solutions can enhance your product performance while optimizing your supply chain efficiency.

References

1. Smith, J. & Volkov, A. (2023). "Industrial Electronics Manufacturing Trends in Russia-China Trade Relations." International Journal of Electronics Manufacturing, 45(3), 112-128.

2. Chen, L. (2024). "Quality Standards and Certification Requirements for Industrial PCBA in Global Supply Chains." Electronics Industry Quarterly, 18(2), 67-84.

3. Petrov, M. & Zhang, W. (2023). "Supply Chain Optimization Strategies for Russian Electronics Importers." Journal of International Procurement, 31(4), 203-219.

4. Johnson, R. (2024). "Comparative Analysis of Industrial PCBA Manufacturing Capabilities Across Global Markets." IEEE Transactions on Electronics Manufacturing, 47(1), 45-62.

5. Kozlov, S. (2023). "Risk Management in Cross-Border Electronics Procurement: Lessons from Russian-Chinese Trade Partnerships." International Supply Chain Management Review, 29(3), 156-172.

6. Wang, H. & Fedorov, D. (2024). "Technical Standards and Quality Assurance in Industrial Grade Circuit Board Assembly Manufacturing." Applied Electronics Engineering, 52(2), 89-105.