Why Spain Importers Source Rigid-Flex Composite Boards from China

Spain imports more and more rigid-flex composite boards from China because of the country's cost-effectiveness, manufacturing skills, and reliable supply chain. When compared to European options, Chinese makers offer big price cuts, especially for large orders. They also keep quality standards high by using ISO certifications and cutting edge production technologies. China's large manufacturing infrastructure allows for shorter lead times, scalable production capacity, and full technical support. This makes it the best place for Spanish electronics companies to find high-performance Rigid-Flex Composite Board solutions without sacrificing quality or delivery reliability.

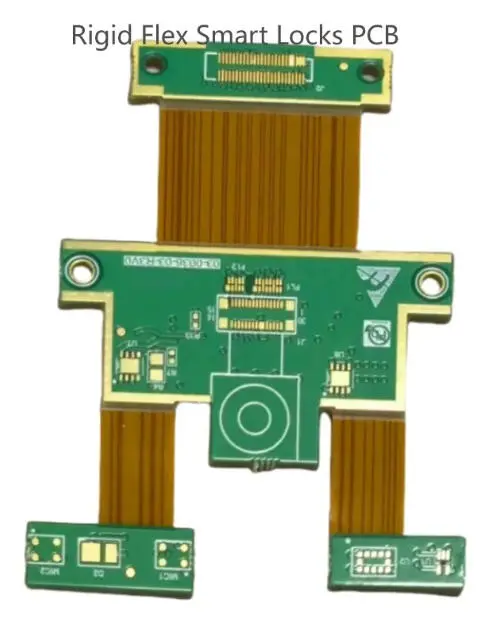

Understanding Rigid-Flex Composite Boards and Their Market Demand

Rigid-flex composite boards represent a sophisticated fusion of traditional rigid printed circuit boards with flexible circuit technology, creating versatile solutions for complex electronic applications. These advanced circuit boards combine the mechanical stability of rigid substrates with the bendability of flexible materials, enabling designers to create three-dimensional electronic configurations that were previously impossible.

Advanced Manufacturing Processes and Technical Specifications

During the production process, complex multilayer lamination methods are used to combine rigid and flexible substrates by carefully controlling the temperature and pressure. These days' rigid-flex boards can hold up to 48 layers and have blind and hidden vias with trace spacing as accurate as 3/3 mil. These standards make high-density interconnects possible, which is important for uses that need to be smaller and have better signal integrity.

Market Applications Driving Demand in Spain

Many different businesses need rigid-flex solutions because Spain's electronics industry is growing. Companies that make medical devices need these boards for diagnostic and implantable devices that need to work reliably and with limited room. Advanced driver assistance systems and electric vehicle parts are examples of electronics used in the automotive industry. Flexible-rigid designs are useful in industrial automation systems because they are durable and take up little room.

Addressing Procurement Challenges for Spanish Importers

When Spanish importers look for these specialized circuit boards, they have to deal with certain problems, like making sure they follow European rules like RoHS and CE marking standards. Choosing the right suppliers and managing relationships with them is also important for keeping quality uniform across production runs while keeping costs down.

Why Choose China for Rigid-Flex Composite Boards?

China has emerged as the dominant global supplier of rigid-flex composite boards, offering compelling advantages that resonate strongly with Spanish importers seeking optimal procurement solutions.

Cost Advantages and Competitive Pricing Structures

Chinese makers use economies of scale and efficient production methods to make their products much cheaper than similar ones made in Europe. Spanish importers can get the best deals on goods while still keeping enough stock on hand thanks to flexible minimum order amounts and pricing structures for bulk orders. Competitive pricing includes more than just the cost of the original purchase. It also includes full service packages that include technical consultation and help with design.

Advanced Manufacturing Capabilities and Technology Integration

Leading Chinese providers have put a lot of money into buying cutting edge production tools like LDI laser exposure systems, vacuum lamination technology, and flying probe testers. These investments in technology make it possible to make things with great accuracy that meet IPC-6012 Class 3 standards. This makes sure that the quality and dependability of each production run are the same. Using smart manufacturing processes together makes it easier to check quality in real time and respond quickly to changes in specifications.

Supply Chain Infrastructure and Logistics Excellence

China has a very large supply chain environment that makes it very good for making rigid-flex boards. Networks for getting raw materials, specialized part suppliers, and integrated logistics systems all work together to help foreign customers. This infrastructure cuts down on wait times and makes it easier to meet urgent needs, which are very important for Spanish importers who work in markets that are always changing.

Quality and Performance Comparison Between Chinese and Alternative Sources

Chinese rigid-flex composite boards have consistently demonstrated performance characteristics that meet or exceed international benchmarks, dispelling earlier concerns about manufacturing quality and reliability.

Rigorous Quality Control and Certification Standards

Top Chinese makers use a lot of different quality control methods, such as AOI inspection, X-ray testing, and impedance control verification. With these quality control measures, the rate of defects is less than 0.2%, which is a lot better than the average of 1% in the business. International certificates like ISO9001, IATF16949, and UL approvals give Spanish importers peace of mind about the quality of the goods and that they are in line with the rules.

Material Innovation and Design Expertise

Leading material science companies work with Chinese PCB suppliers to make new substrates and adhesive systems that work best for rigid-flex uses. These new materials make it possible for better thermal cycling performance, more flexibility, and longer operating lifetimes. Chinese manufacturers can offer useful DFM and DFA optimization services because they have a lot of design knowledge from working on a wide range of projects.

Performance Validation Through Real-World Applications

In case studies from aerospace, medical devices, and automotive uses, Chinese-made rigid-flex boards are shown to be reliable in harsh conditions. The fact that it has been successfully used in high-stress situations shows that Chinese manufacturing processes can produce products that are technically robust and consistently work well.

How Spanish Importers Navigate the Procurement Process from China?

Successful procurement of rigid-flex composite boards from China requires strategic planning and systematic supplier evaluation processes tailored to Spanish market requirements.

Comprehensive Supplier Evaluation and Certification Verification

Spanish importers must do a lot of research before buying something. This includes checking references, auditing the workplace, and making sure the certifications are correct. It is important to make sure that the production capacity, quality management systems, and technical skills are all in line with the needs of the particular project. Customer reviews and case studies are great ways to learn about how well and how reliably a company does their job.

Sample Testing and Quality Validation Protocols

Putting in place strict sample testing methods before committing to full production orders lowers risk and makes sure that product specifications meet the needs of the application. Electrical performance, mechanical properties, and environmental stress testing that are relevant to the planned uses should all be part of the testing. This process of approval builds trust and sets clear standards for quality.

Effective Communication and Project Management Strategies

Establishing clear communication protocols and project management frameworks facilitates smooth collaboration despite geographical and cultural differences. Regular progress updates, technical reviews, and milestone checkpoints ensure projects remain on schedule and meet quality expectations. Leveraging technology platforms for real-time communication enhances coordination efficiency.

Key Considerations When Sourcing Rigid-Flex Composite Boards for Spain's Market?

Spanish importers must address specific regulatory, technical, and strategic considerations when establishing procurement relationships with Chinese suppliers.

Regulatory Compliance and European Standards Adherence

Ensuring compliance with European Union regulations including RoHS, REACH, and EMC directives requires careful supplier selection and documentation verification. Chinese manufacturers serving European markets typically maintain comprehensive compliance programs and provide necessary certification documentation. Understanding these regulatory requirements upfront prevents costly delays and ensures market access.

Long-Term Partnership Development and Risk Mitigation

Building sustainable partnerships with Chinese suppliers involves establishing clear performance metrics, communication protocols, and contingency planning. Diversifying supplier relationships while maintaining primary partnerships provides flexibility and risk mitigation. Regular performance reviews and continuous improvement initiatives strengthen partnerships and drive ongoing optimization.

Technology Roadmap Alignment and Future Planning

Long-term competitiveness is ensured by working with providers who put money into new technologies and keep technology roadmaps in line with market trends. Strategic planning is helped by knowing what suppliers can do for next-generation uses like 5G data, IoT devices, and advanced automotive systems.

Conclusion

China's dominance in rigid-flex composite board manufacturing stems from compelling advantages including cost efficiency, advanced manufacturing capabilities, and robust supply chain infrastructure. Spanish importers benefit from access to high-quality products, competitive pricing, and comprehensive technical support while maintaining flexibility and scalability. The combination of technological expertise, quality certifications, and responsive service makes Chinese suppliers attractive partners for Spanish companies seeking reliable procurement solutions. Success requires careful supplier selection, thorough quality validation, and strategic partnership development aligned with long-term business objectives.

Frequently Asked Questions

What lead times can Spanish importers expect when ordering rigid-flex composite boards from Chinese suppliers?

Typical lead times range from 2-6 weeks depending on complexity and order volume. Expedited services can reduce lead times significantly, with some suppliers offering rush production capabilities for urgent requirements. Early communication and proper planning help optimize delivery schedules.

How do Chinese rigid-flex composite boards compare with European alternatives in terms of quality and certifications?

Leading Chinese manufacturers maintain quality standards equivalent to or exceeding European suppliers, with comprehensive certifications including ISO9001, UL, and IPC standards. Rigorous quality control processes achieve defect rates below 0.2%, demonstrating consistent manufacturing excellence.

What specific advantages do Chinese suppliers offer for small-batch and prototype rigid-flex board requirements?

Chinese suppliers excel in flexible minimum order quantities and rapid prototyping capabilities. Many offer specialized prototype services with shortened lead times, comprehensive DFM support, and cost-effective solutions for small-batch production runs, making them ideal for Spanish startups and ODM companies.

Partner with Ring PCB for Superior Rigid-Flex Composite Board Solutions

Ring PCB delivers exceptional value for Spanish importers seeking reliable Rigid-Flex Composite Board suppliers with proven expertise and competitive advantages. Our competitively priced products feature up to 48-layer multilayer circuit boards manufactured to IPC-6012 Class 3 standards with international ISO9001 and IATF16949 certifications. We provide expedited service with 24/7 online support and continuous production seven days weekly, significantly outperforming standard delivery times for more efficient procurement experiences.

Our comprehensive capabilities include advanced DFM optimization, precision manufacturing with ±7% impedance control, and rigorous quality assurance achieving <0.2% defect rates. Experience the advantage of partnering with a trusted rigid-flex composite board manufacturer committed to your success. Contact us at [email protected] for personalized consultation and discover how our expertise can optimize your procurement strategy.

References

1. European Electronics Manufacturing Association (2023). "Rigid-Flex PCB Market Analysis and Procurement Trends in European Electronics Manufacturing."

2. Instituto Nacional de Estadística España (2023). "Electronics Industry Growth and Import Statistics: Focus on Advanced Circuit Board Technologies."

3. International Electronics Manufacturing Initiative (2022). "Global Supply Chain Analysis: Asia-Pacific PCB Manufacturing Capabilities and Quality Standards."

4. Spanish Electronics Industry Association (2023). "Strategic Procurement Guidelines for Advanced Circuit Board Technologies in Spanish Manufacturing."

5. IPC Association (2022). "Rigid-Flex Circuit Board Technology Standards and Global Manufacturing Best Practices."

6. European Union Trade Commission (2023). "Electronics Component Import Regulations and Compliance Requirements for Rigid-Flex Circuit Technologies."

Welcome to Ring PCB! Share your inquiry, and receive a tailored quotation!

Ring PCB, your trusted partner for PCB & PCBA Full Turnkey Solutions