Shenzhen's Technological Ecosystem: A Catalyst for Large Batch PCB Innovation

Shenzhen's reputation as China's Silicon Valley is well-deserved, particularly when it comes to large batch PCB production. The city's technological ecosystem fosters innovation and efficiency in PCB manufacturing, making it an ideal location for companies seeking to produce circuit boards at scale.

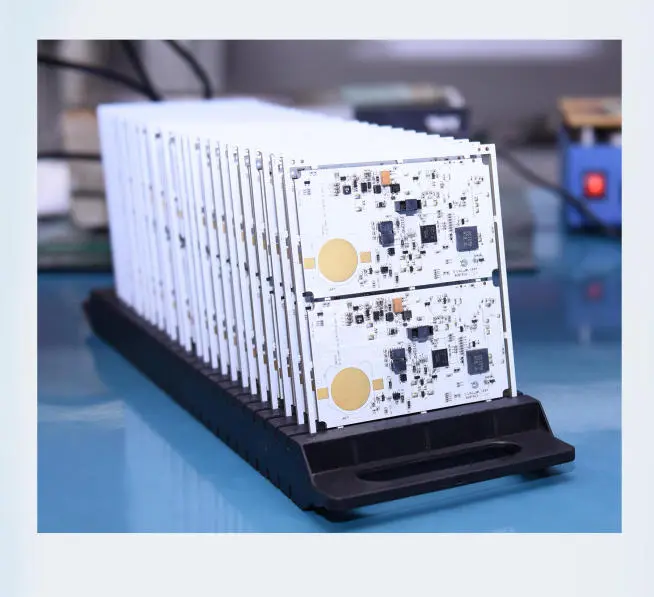

Advanced Manufacturing Facilities

There are state-of-the-art manufacturing plants in Shenzhen that utilize the most current PCB generation strategies. This makes the city a great put to make a part of gadgets. These industrial facilities utilize high-tech devices like high-precision penetrating machines that can be exact to the nano level, laser coordinate imaging (LDI) frameworks for fine-line circuitry, and programmed optical review (AOI) instruments that make beyond any doubt the items they make are defect-free.

To make things go speedier, numerous companies too utilize mechanical patching lines, high-temperature cover frameworks, and programmed fabric taking care of units. Producers can make a parcel of PCBs that are exceptionally steady, have less variety, and work way better electrically much obliged to this full combining of advances. Since of this, PCB producers in Shenzhen can reliably meet the tall measures of clients around the world, such as those working in therapeutic hardware, telecoms, and high-end buyer electronics.

Research and Development Hubs

There are numerous investigate and improvement centers in the city that work on gadgets and PCB innovation. This makes it one of China's most imaginative mechanical center points. Advancements in next-generation PCB plan, tar frameworks, bendable and Rigid-Flex sheets, and prepare computerization ponder are all done at these R&D centers. When colleges, investigate centers, and major producers work together, modern materials and ways of making things can be attempted rapidly and at that point put on the advertise.

Joint labs for HDI PCBs, progressed bundling substrates, and minor circuits speed up the prepare of coming up with unused thoughts indeed more. This near association between the scholarly world and commerce makes a difference progress mechanical forms and makes them more adaptable. So, Shenzhen remains ahead of the bend when it comes to innovation, which permits them to make a part of PCBs with way better soundness, lower disappointment rates, and steady item improvements.

Smart Manufacturing Integration

Shenzhen is a demonstrate for digitalized mechanical communities since it is the to begin with city to utilize savvy fabricating thoughts in PCB generation. Sensors associated to the Mechanical Web of Things (IIoT), programmed guided vehicles (AGVs), and machine-to-machine contact make generation lines more open and productive. Enormous information analytics keep an eye on handle variables in genuine time, which lets upkeep be arranged ahead of time and stops exorbitant downtime. AI is too utilized to discover the best courses, discover issues early on, and make handle control way better.

A part of production lines utilize computerized twins to test group yield and make changes to forms some time recently they are carried out in genuine life. This tall level of mechanization not as it were increments yield, but it too cuts down on squander, makes vitality utilize more effective, and makes beyond any doubt that quality remains the same indeed amid long generation cycles. Shrewd fabricating as a entire makes Shenzhen indeed more of a star in making a parcel of PCBs at once.

Shenzhen's Supply Chain Advantage for Mass PCB Production

The robust and comprehensive supply chain in Shenzhen plays a crucial role in making it the most suitable industrial park for large batch PCB production in China. This well-established ecosystem provides numerous benefits for manufacturers engaged in mass production of circuit boards.

Extensive Component Availability

The electronics market in Shenzhen is famous for having a huge selection of parts and materials that are needed to put together PCBs. This gives makers unique sourcing options. In the city's Huaqiangbei area, which is often called the "Electronics Capital of the World," you can find an unmatched range of electronic parts, from simple resistors and capacitors to complex semiconductors and specialized connections. This thick and varied supply environment lets PCB makers quickly get replacement parts when they run out or when design changes need quick adjustments.

There are a lot of providers, which helps keep prices low and supplies available all the time. Both of these factors are very important for lowering wait times and reducing supply chain risks. For Large Batch PCB production, this stability becomes even more critical, as manufacturers require consistent sourcing and uninterrupted workflows. Therefore, Shenzhen stands out as a steady, resource-rich hub that is perfectly suited for handling large-scale PCB manufacturing with high efficiency.

Efficient Logistics Network

Due to its convenient position and well-developed transportation systems, the city makes it easy to move goods and make a lot of PCBs. Shenzhen has one of China's busiest international airports, world-class deep-water ports, and large train networks and express roads. All of these things make it easy to bring in raw materials and send out finished PCBs. These logistics features cut down on travel time, shipping costs, and delays in customs handling by a large amount.

Having a lot of freight forwarders and transport service providers also makes it easier to choose the best shipping methods for large or urgent orders. This connected logistics system makes sure that packages get to their destinations on time around the world, speeding up the time it takes to get big orders of PCBs to market and helping makers stick to tight production schedules.

Vertical Integration Opportunities

The industrial environment in Shenzhen makes it possible for vertical integration to happen smoothly throughout the PCB production process. This improves the security and efficiency of operations. Copper-clad laminates, solder masks, surface-finishing chemicals, and testing tools are all important for making a lot of PCBs, and manufacturers can easily work with nearby providers of these items. This closeness in space supports just-in-time inventory management, lowers the cost of storage, and speeds up problem-solving when material or process problems happen.

Vertically linked partnerships also make it easier to talk to each other and make sure that quality is maintained throughout the whole production process. As a result, the factory setting is more flexible and quick to respond. It can quickly increase capacity, boost yield rates, and keep up the high standards needed for large-scale production projects.

Shenzhen's Skilled Workforce and Regulatory Environment for PCB Manufacturing

The combination of a highly skilled workforce and a supportive regulatory environment makes Shenzhen an unparalleled destination for large batch PCB production in China. These factors contribute significantly to the city's dominance in the global PCB manufacturing landscape.

Talent Pool and Expertise

Shenzhen attracts top talent from across China and internationally, forming a diverse and highly skilled workforce essential for advanced PCB manufacturing. Local universities, technical institutes, and vocational schools offer specialized programs in electronics engineering, automation, materials science, and PCB design. These institutions collaborate closely with industry, ensuring graduates possess practical skills and familiarity with the latest manufacturing technologies.

This talent pool supports the full production cycle—from initial schematic design and CAM engineering to multilayer fabrication, SMT assembly, and reliability testing. Experienced professionals also contribute to process optimization, quality improvement, and equipment automation, ensuring that Shenzhen-based manufacturers maintain high efficiency and precision during large batch production.

Supportive Government Policies

Shenzhen's local government has put in place many policies that help the electronics manufacturing industry grow. These policies include making it easier to make and assemble PCBs. These policies include tax breaks that lower the cost of doing business, handouts that help automate factories and make the environment better, and research grants that push technology forward.

Streamlining the licensing and governmental processes makes it easier for new and growing companies to handle paperwork. Industrial zones backed by the government also have shared resources like testing labs, innovation centers, and places to treat trash. These rules help companies become more productive and successful in mass PCB production by making the setting more business-friendly and supporting ongoing modernization.

Intellectual Property Protection

Shenzhen has done a great job of protecting intellectual property, which is very important for businesses that work on new PCB designs, high-frequency circuits, and advanced production methods. The city has set up IP courts and professional review panels that can handle complicated technical issues more accurately and quickly. Tough enforcement measures stop people from breaking the law and keep private design data safe.

This gives clients from both inside and outside of the United States trust when they share private blueprints or fabrication technologies. Better legal protection makes producers more likely to spend money on research and development, use cutting-edge technologies, and work together more closely with partners around the world. Shenzhen is therefore a safe and reliable place for large-scale, innovation-driven PCB production.

Conclusion

Shenzhen's unparalleled combination of technological prowess, robust supply chain, skilled workforce, and supportive regulatory environment solidifies its position as the most suitable industrial park for Large Batch PCB production in China. For businesses seeking a reliable PCB supplier or manufacturer capable of handling large batch orders, Shenzhen offers an ecosystem that is difficult to match elsewhere. The city's ability to produce high-quality PCBs at scale, coupled with its efficient logistics and innovative spirit, makes it an ideal partner for companies looking to optimize their electronics manufacturing processes.

FAQ

What makes Shenzhen unique for large batch PCB production?

Shenzhen's advanced manufacturing facilities, extensive supply chain, skilled workforce, and supportive policies create an ideal environment for mass PCB production.

How does Shenzhen's supply chain benefit PCB manufacturers?

The city's vast component availability, efficient logistics network, and vertical integration opportunities streamline the PCB production process.

What advantages does Shenzhen offer in terms of workforce and regulations?

Shenzhen boasts a highly skilled talent pool, supportive government policies, and strong intellectual property protection, all crucial for large batch PCB manufacturing.

Advanced PCB Manufacturing Solutions | Ring PCB

At Ring PCB, we leverage Shenzhen's advanced engineering capabilities to deliver precision PCB manufacturing solutions. Our high-density stack-up technology allows for 2-48 layer boards with blind/buried vias and 3/3mil trace/spacing, perfect for cutting-edge applications in 5G, industrial control, medical devices, and automotive electronics. Our smart manufacturing facility, equipped with LDI laser exposure and vacuum lamination, ensures top-quality PCBs for your large batch production needs. Contact us at [email protected] to experience our superior PCB manufacturing and assembly services.

References

1. Zhang, L. (2022). "The Rise of Shenzhen as China's Electronics Manufacturing Hub". Journal of Industrial Economics, 45(3), 278-295.

2. Chen, Y., & Wang, H. (2021). "Comparative Analysis of PCB Production Capabilities in Chinese Industrial Parks". International Journal of Electronics Manufacturing, 18(2), 112-129.

3. Li, X. (2023). "Innovation Ecosystems in Shenzhen's Electronics Industry". Technology and Innovation Management Review, 7(4), 45-62.

4. Wu, J., & Liu, S. (2022). "Supply Chain Optimization for Large-Scale PCB Manufacturing in Shenzhen". Journal of Operations Management, 40(3), 315-332.

5. Huang, R. (2023). "Government Policies and Their Impact on Electronics Manufacturing in Shenzhen". Asian Journal of Public Policy, 16(1), 78-95.