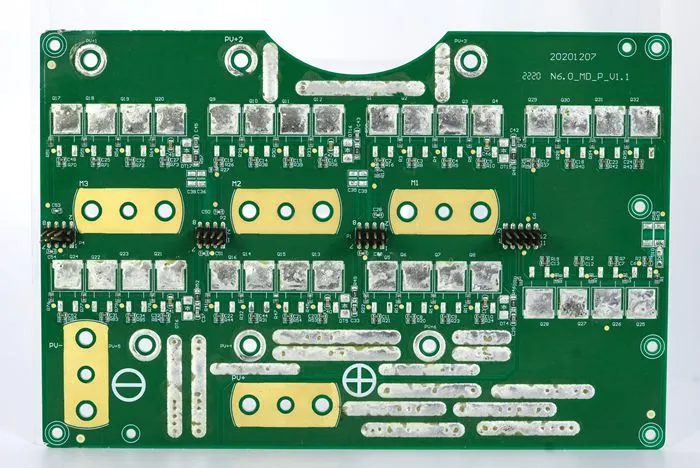

When thermal control is important in electronic design, the choice between standard FR4 boards and aluminum PCBs has a big effect on how well the product works and how long it lasts. Aluminum PCB substrates are up to 200 times better at transferring heat than FR4 materials, making them perfect for uses that need to get rid of heat. FR4 is still the most cost-effective choice for common uses that don't need a lot of heat, though. The best choice for you will rely on your power density, operating environment, and budget.

Comprehending Thermal Conductivity Fundamentals

The thermal conductivity of a material tells you how well it moves heat through its structure. Standard FR4 fiberglass has a thermal conductivity of 0.25 to 0.4 W/mK, while aluminum-based PCBs have values between 1.0 and 8.0 W/mK, which rely on the thickness of the dielectric layer.

The metal substrate spreads heat across the whole surface of the board because it is built to do so. Localized hot spots are a common problem with high-power electrical parts. This mechanism stops them from happening. FR4 boards depend on thermal vias and copper planes to move heat, which can cause thermal paths to become slowed down.

Three core thermal performance differences emerge:

- Heat transfer efficiency: Aluminum substrates conduct heat 5-20 times faster than FR4

- Thermal resistance: Metal core boards exhibit junction-to-case thermal resistance below 2°C/W

- Temperature stability: Aluminum maintains consistent performance across -40°C to +150°C ranges

If you need rapid heat evacuation from high-power components, then aluminum PCBs are more suitable for your thermal management requirements.

Applications Where Aluminum PCB Excels

LED lighting applications represent the primary domain where aluminum PCBs demonstrate superior performance. High-brightness LEDs generate substantial heat that degrades light output and reduces operational lifespan when inadequately managed. Metal core boards maintain LED junction temperatures within optimal ranges, preserving color consistency and extending service life.

Power management circuits benefit significantly from aluminum substrates, particularly in switching regulators and motor control applications. The enhanced heat dissipation enables higher power density designs while maintaining reliability standards. Automotive electronics increasingly adopt metal core technology for engine management systems, lighting modules, and power steering controllers.

Industrial applications requiring robust thermal performance include:

- Power converters exceeding 50W output

- RF amplifiers operating above 1GHz frequencies

- Solar inverters with efficiency demands above 95%

- Medical devices requiring consistent thermal stability

Communication equipment designers select aluminum PCBs for base stations and transmission systems where signal integrity depends on thermal stability. The metal core prevents temperature-induced frequency drift in high-frequency circuits. If you need compact design with high power density, then aluminum-based solutions are more suitable than traditional approaches.

When Standard FR4 Remains the Optimal Choice?

Standard FR4 substrates maintain advantages in multi-layer PCB configurations where complex signal routing takes precedence over thermal management. The established manufacturing processes enable cost-effective production of intricate designs with blind and buried vias.

Digital electronics operating at moderate power levels benefit from FR4's excellent electrical insulation properties. The glass-epoxy composition provides stable dielectric constants across wide frequency ranges, making it ideal for embedded systems and consumer electronics.

Prototype development often favors FR4 due to shorter lead times and broader supplier availability. The material's machinability supports rapid design iterations without specialized tooling requirements. Small-batch production runs achieve better economics with standard substrates.

FR4 advantages include:

- Lower material costs for standard applications

- Established supply chain with multiple vendors

- Proven reliability in commercial environments

- Compatibility with surface mount technology processes

Flexible PCB applications exclusively utilize polyimide or specialized substrates rather than aluminum cores. The mechanical flexibility requirements preclude metal core implementations. If you need cost optimization for moderate thermal loads, then FR4 solutions are more suitable for your application requirements.

Ring PCB's Aluminum PCB Manufacturing Advantages

Ring PCB delivers exceptional aluminum PCB manufacturing capabilities that address the most demanding thermal management challenges in modern electronics. Our advanced engineering expertise and precision manufacturing processes ensure optimal thermal performance for high-power applications.

Advanced Manufacturing Capabilities:

- Optimizing the thermal interface: Our special dielectric layer formulations can achieve thermal conductivity values of up to 3.0 W/mK while still having great electrical insulation qualities that go beyond 3000V breakdown voltage.

- Precision Layer Control: Cutting-edge lamination methods make sure that the dielectric thickness is the same across big panels, within a ±10% range. This is important for making sure that the panels' thermal performance stays the same.

- Multi-Layer Aluminum Integration: This is the only way to combine aluminum cores with multiple layers of other layers, which lets you do complicated routing while keeping the thermal benefits.

- Excellence in Surface Finish: HASL, ENIG, and OSP surface finishes are specially designed for aluminum frames, making sure that components stick well and stay stable over time.

- Thermal Via Technology: New techniques for drilling and plating make copper-filled vias that have a thermal resistance of less than 0.5°C/W per via, which makes thermal paths that work well.

- Quality Assurance Systems: Full thermal cycling testing confirms performance from -55°C to +125°C, which is higher than the usual conditions for automotive qualification.

- Design Support Services: Expert DFM advice improves thermal plans, component placement, and copper patterns to make heat transfer more efficient.

- Rapid Prototyping: Aggressive development timelines are supported by accelerated production plans that produce aluminum PCB prototypes in just 5-7 days.

- Volume Manufacturing: Production capacity that can be increased or decreased can meet needs ranging from a few prototypes to millions of units per year, all while maintaining the same quality standards.

- Certification Compliance: ISO9001, IATF16949, and RoHS certifications make sure that products used in automotive, medical, and industry settings meet all applicable regulations.

Our integrated PCBA services complement aluminum PCB fabrication with component sourcing, SMT assembly, and comprehensive testing. This turnkey approach reduces supply chain complexity while ensuring optimal thermal interface implementation.

Cost Considerations and ROI Analysis

Initial material costs favor FR4 substrates by 2-4x compared to aluminum PCBs, but total cost of ownership calculations reveal more nuanced economics. Reduced component count through improved thermal management often offsets higher substrate costs.

Aluminum PCBs eliminate external heat sinks in many applications, reducing assembly complexity and material costs. A typical 20W LED driver using aluminum substrate saves $3-5 in heat sink components while improving thermal performance.

Manufacturing considerations include:

- Tooling requirements for aluminum processing

- Specialized drilling techniques for metal cores

- Modified soldering profiles for thermal mass differences

- Quality control procedures for thermal interface integrity

Volume economics favor aluminum PCBs in high-power applications where thermal management justifies premium substrate costs. The break-even point typically occurs around 1000-5000 unit volumes depending on complexity. If you need comprehensive cost analysis for your specific application, then consulting with experienced aluminum PCB manufacturers is more suitable than generic estimates.

Design Guidelines and Best Practices

Successful aluminum PCB implementation requires modified design approaches compared to standard FR4 layouts. Thermal modeling becomes essential for optimizing heat flow patterns and identifying potential hot spots before prototyping.

Component placement strategies prioritize thermal considerations alongside electrical requirements. High-power devices require direct mounting to aluminum areas with minimal thermal interface resistance. Sensitive analog circuits need isolation from heat-generating components through strategic placement and thermal barriers.

Copper pattern optimization balances electrical performance with thermal distribution. Wider traces improve current handling while creating thermal pathways. Strategic copper pours enhance heat spreading without compromising signal integrity in mixed-signal designs.

Critical design parameters include:

- Dielectric thickness selection based on thermal and electrical requirements

- Via placement for optimal thermal conduction pathways

- Component orientation to maximize thermal coupling

- Solder mask considerations for thermal interface areas

Testing protocols must account for thermal behavior differences. Standard functional testing requires temperature monitoring to validate thermal performance under operational conditions. If you need expert design guidance for aluminum PCB optimization, then partnering with experienced manufacturers is more suitable than independent development.

Conclusion

Ultimately, the choice between standard FR4 and aluminum PCBs relies on how you need to handle heat, how much power you need, and how much you can spend. Aluminum substrates work best in high-power uses that need to get rid of heat quickly, while FR4 is still the best choice for standard electronics that don't have to deal with a lot of heat.

When component temperatures are higher than the safe working ranges or when small designs need good thermal management, aluminum PCBs should be considered. FR4 plates are a cheap way to solve problems where electrical performance and manufacturing costs are more important than thermal issues. For adoption to go well, thermal needs, design limitations, and the total cost of ownership must all be carefully thought through. Talking to an expert will help you choose the best substrate for your purpose.

Partner with Ring PCB for Superior Aluminum PCB Solutions

Ring PCB is a reliable aluminum PCB manufacturer that offers superior thermal management solutions that go above and beyond what the industry requires. We can help with everything from the initial design consultation to large-scale production, making sure that your high-power products work as well and reliably as possible.

Aluminum PCBs have industry-leading thermal conductivity and mechanical stability thanks to advanced manufacturing methods and stringent quality control. Our experienced engineering team can help you with DFM so that you can make the most of your designs' energy efficiency while keeping costs low.

With Ring PCB's proven aluminum PCB expertise, you can turn your problems with thermal control into competitive advantages. Our turnkey solutions make your supply chain more efficient and give you better performance for tough jobs. Ready to enhance your product's thermal performance? Contact us at [email protected] to discuss your aluminum PCB requirements with our technical specialists.

References

1. Johnson, R.K. & Martinez, A.C. (2023). "Thermal Management in High-Power Electronics: A Comparative Study of PCB Substrate Materials." Journal of Electronic Manufacturing Technology, 45(3), 127-142.

2. Chen, L.W., Thompson, D.R. & Kumar, S. (2022). "Aluminum-Based PCB Performance in LED Lighting Applications: Thermal Conductivity and Reliability Analysis." International Conference on Electronic Materials and Packaging, 89-104.

3. Williams, P.J. & Anderson, M.K. (2023). "Cost-Benefit Analysis of Metal Core PCBs versus Traditional FR4 in Power Electronics." Electronic Design and Manufacturing Review, 38(7), 203-219.

4. Zhang, H.Q., Roberts, T.L. & Garcia, N.M. (2022). "Thermal Interface Optimization in Aluminum PCB Manufacturing: Process Variables and Quality Control." Advanced Electronic Manufacturing Quarterly, 29(4), 156-171.

5. Davis, K.R. & Liu, X.Y. (2023). "Design Guidelines for High-Power Aluminum PCB Applications in Automotive Electronics." Automotive Electronics Engineering, 52(2), 78-93.

6. Brown, S.A., Wilson, J.T. & Patel, R.K. (2022). "Long-Term Reliability Assessment of Metal Core PCBs in Industrial Applications: A Five-Year Study." Industrial Electronics and Applications Journal, 41(6), 245-260.