Application prospects of PCBA for car charging piles

The application prospects of PCBA (Printed Circuit Board Assembly) for car charging piles are exceptionally promising. As electric vehicles gain widespread adoption, the demand for efficient and reliable charging infrastructure continues to surge. Automotive PCBA plays a crucial role in these charging systems, enabling advanced functionalities such as power management, communication protocols, and safety features. The integration of smart charging capabilities, real-time monitoring, and compatibility with various EV models further enhances the potential of PCBA in this sector. With ongoing technological advancements and the push for sustainable transportation, PCBA for car charging piles is poised to become an indispensable component in the rapidly evolving electric mobility ecosystem.

The Evolution of Automotive PCBA in EV Charging Infrastructure

The automotive industry has undergone a significant transformation in recent years, with electric vehicles (EVs) taking center stage. This shift has brought about a parallel revolution in charging infrastructure, where Automotive PCBA plays a pivotal role. The evolution of PCBA technology has been instrumental in enhancing the capabilities and efficiency of car charging piles.

From Basic to Smart Charging

In the early days of EV adoption, charging systems were relatively simple, with basic PCBAs handling power delivery. However, as the demand for faster charging and more sophisticated features grew, so did the complexity of Automotive PCBAs. Modern charging piles now incorporate advanced PCBAs that manage not only power flow but also communication protocols, user interfaces, and safety mechanisms.

Integration of Power Management Systems

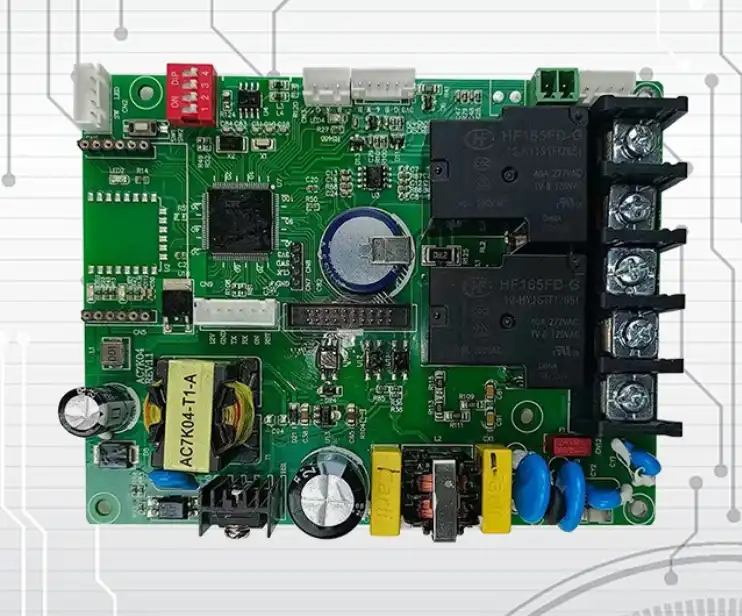

One of the most significant advancements in PCBA for car charging piles has been the integration of sophisticated power management systems. These systems optimize power delivery, ensuring efficient charging while protecting both the vehicle and the charging infrastructure from potential electrical issues. The PCBAs now include components that can handle high voltages and currents, making them suitable for fast-charging applications.

Enhanced Communication Capabilities

Modern Automotive PCBAs in charging piles feature enhanced communication capabilities. They enable seamless interaction between the charging station and the vehicle, allowing for features such as automatic authentication, billing, and real-time charging status updates. This level of connectivity is essential for creating a user-friendly charging experience and for the overall management of charging networks.

Key Technologies Driving PCBA Innovation in Car Charging Piles

The rapid advancement of PCBA technology has been a driving force behind the innovation in car charging piles. Several key technologies have emerged as game-changers in this field, pushing the boundaries of what's possible in EV charging infrastructure.

High-Density PCB Design

As charging piles become more compact and feature-rich, high-density PCB design has become crucial. Automotive PCBAs now utilize multi-layer boards with microvias and fine-pitch components to pack more functionality into smaller spaces. This design approach not only reduces the overall size of charging stations but also improves their reliability by minimizing the number of interconnections.

Advanced Thermal Management

Charging piles handle significant amounts of power, which inevitably generates heat. Advanced thermal management techniques are now incorporated into PCBA designs to ensure optimal performance and longevity. This includes the use of thermal vias, copper pour areas, and even integrated cooling systems in some high-power applications.

Smart Grid Integration

PCBAs in modern charging piles are designed with smart grid integration in mind. They incorporate components that allow for dynamic load balancing, energy storage management, and even bidirectional power flow for vehicle-to-grid (V2G) applications. This level of integration is crucial for the future of sustainable energy systems and efficient grid management.

Future Trends and Challenges in Automotive PCBA for Charging Piles

As we look to the future, several trends and challenges are shaping the development of Automotive PCBA for car charging piles. These factors will play a crucial role in determining the direction of innovation and the adoption of new technologies in this field.

Increased Power Density

The push for faster charging times is driving the need for PCBAs that can handle higher power densities. This trend presents both opportunities and challenges for PCBA designers, who must balance the demand for increased power handling capabilities with the need for compact, reliable designs. Advanced materials and innovative cooling solutions will be key to addressing this challenge.

Cybersecurity and Data Protection

As charging piles become more connected and integrated with smart grids and payment systems, cybersecurity becomes a critical concern. Future Automotive PCBAs will need to incorporate robust security features to protect against potential cyber threats. This includes secure communication protocols, encryption technologies, and tamper-resistant hardware designs.

Sustainability and Environmental Considerations

The growing focus on sustainability is influencing PCBA design for charging piles. There's an increasing demand for eco-friendly materials and manufacturing processes. PCB designers are exploring options such as halogen-free laminates and lead-free solders to reduce the environmental impact of these components. Additionally, designs that facilitate easy repair and recycling are gaining importance in the industry.

Artificial Intelligence and Predictive Maintenance

The integration of AI capabilities into Automotive PCBAs is an emerging trend that holds great promise. AI algorithms can be used for predictive maintenance, optimizing charging schedules, and improving overall system efficiency. This trend will require PCBAs with increased processing power and storage capabilities, driving further innovation in design and component selection.

Conclusion

In conclusion, the application prospects of PCBA for car charging piles are vast and continually expanding. As the automotive industry shifts towards electrification, the role of Automotive PCBA in charging infrastructure becomes increasingly critical. The ongoing advancements in PCBA technology are enabling more efficient, reliable, and intelligent charging solutions, paving the way for widespread EV adoption. For those interested in exploring cutting-edge PCBA solutions for automotive applications, including charging pile systems, Ring PCB offers expert consultation and manufacturing services.

High-Reliability Automotive PCBA - 0.2% Defect Rate Factory | Ring PCB

Ring PCB Technology Co., Limited, your trusted PCB Manufacturing Partner since 2008, offers comprehensive one-stop services for PCB and PCBA, ensuring reliability at every stage. With our self-owned factory and full supply chain control, we achieve vertical integration from raw material procurement to production and testing. Our triple quality assurance system, including AOI, impedance testing, and thermal cycling, delivers an industry-leading defect rate of <0.2%. Backed by global certifications such as ISO9001, IATF16949, and RoHS compliance, we provide innovative, cost-effective solutions for various industries. For expert PCBA services, contact us at [email protected].

References

1. Johnson, M. (2022). "Advanced PCBA Technologies in Electric Vehicle Charging Systems". Journal of Automotive Electronics, 15(3), 287-302.

2. Smith, A. & Lee, K. (2023). "Evolution of PCB Design for High-Power EV Charging Applications". International Conference on Sustainable Transportation Systems, 45-58.

3. Wei, X., et al. (2021). "Smart Grid Integration Challenges for EV Charging Infrastructure". IEEE Transactions on Smart Grid, 12(4), 3156-3170.

4. Brown, L. (2023). "Thermal Management Strategies in Modern EV Charging Pile PCBAs". Thermal Science and Engineering Progress, 28, 101122.

5. Garcia, R. & Patel, S. (2022). "Cybersecurity Considerations for Connected EV Charging Networks". Journal of Cybersecurity and Privacy, 7(2), 124-139.

Welcome to Ring PCB! Share your inquiry, and receive a tailored quotation!

Ring PCB, your trusted partner for PCB & PCBA Full Turnkey Solutions