In order to find certified Turnkey PCB assembly manufacturers in China, you need to know how to use key evaluation factors, quality standards, and strategic sourcing approaches. Chinese companies make most of the electronics that are put together around the world. They offer full solutions, from making PCBs to checking the finished products. To be successful, you need to find partners who have strong certifications, proven technical skills, and quality management systems that work and meet foreign standards.

China's Manufacturing Excellence in Electronic Assembly

Advanced Infrastructure and Technology Integration

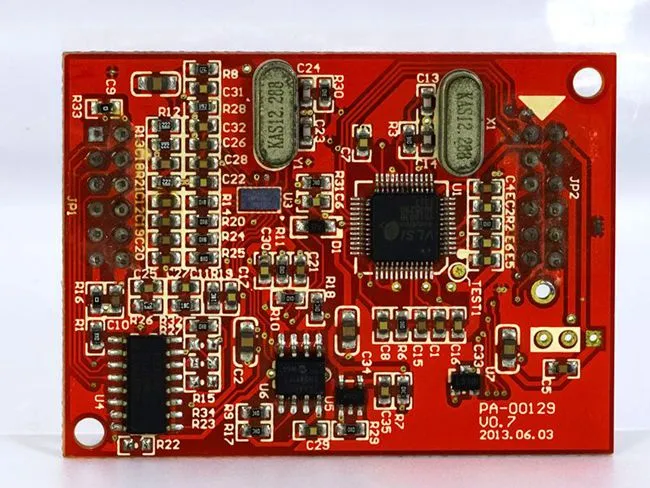

Over the past ten years, China has put a lot of money into building up its industrial infrastructure to the highest standards. Automated optical inspection systems, precise pick and place tools, and high-tech solder paste printing equipment can be found in modern facilities. Because of these improvements in technology, manufacturers can now make complex multilayer PCBs with trace spacing as small as 3/3mil and still get very high yield rates.

Comprehensive Supply Chain Ecosystem

An ecosystem that is unmatched is made up of a lot of producers of electronic parts, raw materials, and specialized services. This integration makes it easier to find the right bill of materials, cuts down on wait times, and offers cheap prototype assembly services. Manufacturers can usually get parts within 24 to 48 hours, which greatly shortens the time it takes to finish a job.

Skilled Workforce and Engineering Expertise

Chinese companies that make things have highly trained tech teams that focus on making designs easier to make. These professionals work closely with clients to spot early on possible production problems, suggest ways to make designs better, and put cost-cutting plans into action without lowering quality standards

Strategic Approaches for Manufacturer Selection

Technical Capability Assessment

Look at possible partners' equipment specs and how well they can do your process. Look for companies that have advanced lines for surface mount technology, automated inspection systems, and full testing centers. Ask for thorough lists of their equipment and process flow diagrams to see if they can meet your needs.

Quality Management System Evaluation

Check out the company's quality control methods, such as inspecting incoming materials, keeping an eye on the production process, and making sure the end product meets all standards. Partners you can trust keep thorough records of quality metrics, use statistical process control, and give full test reports for every shipment.

Customer Reference and Case Study Analysis

Ask for customer reviews and in-depth case studies from businesses or uses that are similar to yours. Pay attention to examples that show the manufacturer can handle difficult technical problems, meet tight deadlines, and keep quality consistent across multiple production runs. For example, look at Turnkey PCB assembly solutions that show how well they can handle the whole production process.

Communication and Project Management Capabilities

Check out the communication systems that the manufacturer uses, such as the project managers, engineering support teams, and real-time monitoring systems for output. Clear communication keeps everyone on the same page and makes sure that the project goes smoothly from the initial quote to the final delivery.

Financial Stability and Business Continuity

Check the manufacturer's financial health by looking at proof of business registration, proof of facility ownership, and long-term customer ties. Stable partners keep upgrading their tools and keep up the same level of service even when the market changes.

Essential Certification Standards and Compliance Requirements

ISO Quality Management Certifications

Getting ISO 9001 certification shows that you follow the rules for quality control around the world. For uses in the automotive business, IATF 16949 certification makes sure that the requirements of that industry are met. Medical device makers should give more weight to ISO 13485-certified centers that know how to follow regulations for medical electronics.

Environmental and Safety Compliance

RoHS compliance makes sure that goods follow the rules set by the European Union for dangerous substances. Getting a WEEE license shows that you know how to properly handle electronic waste. These certifications show that you care about the environment and make it easier for finished goods to get sold around the world.

Industry-Specific Certifications

UL certification proves that electrical goods going to North American markets meet safety standards. IPC certification makes sure that industry standards for electronics assembly are followed. For example, IPC-6012 Class 3 requirements for high-reliability uses are met.

Effective Sourcing Channels and Platform Strategies

Professional B2B Platforms

Alibaba and Made-in-China serve as primary discovery platforms, but success requires careful supplier verification. Focus on Gold Supplier status, trade assurance programs, and verified facility assessments. Use platform messaging systems to document all communications and maintain audit trails.

Industry Trade Shows and Exhibitions

Events like Electronica China and NEPCON provide opportunities for face-to-face meetings with potential suppliers. These venues allow hands-on evaluation of sample products, direct technical discussions, and relationship building with key personnel, including those offering Turnkey PCB assembly solutions that demonstrate comprehensive manufacturing capabilities.

Professional Referrals and Industry Networks

Leverage existing supplier relationships for referrals to trusted assembly partners. Industry associations and professional networks often provide vetted supplier recommendations based on member experiences and performance data.

OEM/ODM Partnership Development Strategies

Intellectual Property Protection

Establish comprehensive non-disclosure agreements before sharing technical documentation. Verify the manufacturer's IP protection policies and previous customer confidentiality track records. Consider splitting design files across multiple suppliers for sensitive applications.

Design Collaboration and Engineering Support

Partner with manufacturers offering design for assembly consulting services. These collaborations often result in 15-30% cost reductions through component standardization, process optimization, and yield improvement initiatives.

Long-term Partnership Development

Structure agreements that encourage continuous improvement and cost reduction over time. Implement performance metrics, regular business reviews, and shared development roadmaps that align both parties' interests.

MOQ Optimization and Cost Negotiation Techniques

Volume Commitment Strategies

To get better prices, bundle more than one product line or agree to annual volume forecasts. Many manufacturers offer big discounts to customers who buy from them more than once, which makes specialized production line setups worthwhile.

Flexible MOQ Arrangements

Talk about graduated MOQ frameworks that can be used as the business grows. Start with higher prices per unit for smaller amounts at first, and then move to more optimal pricing as the amounts go up. This method lowers the original investment while setting up relationships for production.

Total Cost of Ownership Analysis

Look at the total delivered costs of each plan, which should include the costs of testing, packaging, logistics, and making the tools. When complete service packages get rid of the need to work with multiple vendors, higher assembly costs can lead to lower total program costs.

Factory Audit Protocols and Quality Assurance

Pre-qualification Audit Procedures

Conduct comprehensive facility assessments covering equipment capabilities, quality systems, and workforce qualifications. Use standardized audit checklists that evaluate critical control points throughout the assembly process.

Ongoing Performance Monitoring

Implement regular quality reviews, delivery performance tracking, and customer satisfaction surveys. Establish clear corrective action procedures for addressing performance deficiencies and continuous improvement initiatives, including Turnkey PCB assembly services to optimize production workflows and enhance overall service delivery.

Supply Chain Risk Management

Assess supplier diversification strategies, backup facility capabilities, and business continuity planning. Understanding risk mitigation approaches helps ensure uninterrupted production during unexpected disruptions.

Leading Supplier Characteristics for 2026

Digital Manufacturing Integration

Industry 4.0 technologies, such as real-time output monitoring, predictive maintenance systems, and automated quality feedback loops, are used by the best suppliers. These features make things run more smoothly and give customers a whole new level of information about how work is going.

Sustainability and Environmental Responsibility

Major producers put money into programs that reduce waste, use renewable energy, and create a circular economy. These promises lessen the damage to the environment and often save money that lowers prices for customers.

Advanced Technical Capabilities

Some of the specialized services that premier providers offer are signal integrity analysis, thermal management consulting, and embedded software integration. These features that add value help customers speed up the time it takes to get a product to market while also lowering the overall cost of development.

Conclusion

To find the best turnkey PCB assembly maker in China, you need to carefully look at their technical skills, quality systems, and how they run their business. To be successful, you need to do your research, be clear about what you need, and form partnerships that are good for both sides. The best makers use cutting-edge technology, have a lot of certifications, and have a history of making customers happy. Companies can build relationships that give them big competitive benefits by lowering costs, raising quality, and shortening the time it takes to make a new product by using structured selection processes and keeping expectations realistic.

FAQ

What is the lowest amount of PCB assembly that I can buy from a Chinese company?

MOQs are very different depending on how complicated the product is and how well the maker can make it. MOQs for simple assemblies can be as low as 100 pieces, but MOQs for complicated multilayer boards are usually between 500 and 1000 pieces. There are a lot of producers that are flexible about how many prototypes they make and how much they cost.

How can I make sure that a company's claims about licensing are true?

Ask for original certification papers and use the databases of the organizations that issued them to make sure they are real. Reliable makers give out certificate numbers that can be checked by anyone else. Think about getting third-party audits for applications that are very important and need the highest level of trust.

How long do most turnkey assembly jobs take to finish?

Typical lead times are two to three weeks for easy assemblies and four to six weeks for complicated projects that need unique parts. You can pay extra for expedited orders, but for the best cost-effectiveness, big orders usually need 6 to 8 weeks to be processed.

Partner with Ring PCB for Superior Turnkey PCB Assembly Solutions

Ring PCB combines advanced manufacturing capabilities with comprehensive quality assurance to deliver exceptional turnkey PCB assembly services. Our self-owned facility features cutting-edge equipment including LDI laser exposure systems and automated optical inspection technology, ensuring consistent quality across all production volumes. With ISO9001 and IATF16949 certifications, we maintain defect rates below 0.2% while providing complete design for manufacturability support. Contact us at [email protected] to discuss your specific requirements with our experienced engineering team.

References

1. Institute for Printed Circuits. "IPC-6012 Qualification and Performance Specification for Rigid Printed Boards." IPC Standards Manual, 2023 Edition.

2. Chen, Wei and Liu, Xiaoming. "Quality Management Systems in Chinese Electronics Manufacturing: A Comparative Analysis." Journal of Manufacturing Technology, Volume 45, Issue 3, 2024.

3. European Electronics Manufacturing Association. "Global PCB Assembly Market Analysis and Certification Requirements." Annual Industry Report, 2024.

4. Zhang, Lei et al. "Supply Chain Optimization in Asian Electronics Manufacturing Hubs." International Journal of Production Research, Volume 62, Issue 8, 2024.

5. International Quality Standards Organization. "ISO 9001:2015 Implementation Guidelines for Electronics Assembly Operations." Quality Management Handbook, 2024 Revision.

6. Thompson, Mark and Singh, Raj. "Emerging Trends in Turnkey PCB Assembly: Technology and Market Dynamics." Electronics Manufacturing Quarterly, Spring 2024 Issue.