Full turnkey PCBA solutions, which comprise everything from idea to delivery, are an example of a full manufacturing approach. This strategy makes sure that one company is in charge of all aspects of your printed circuit board assembly job. The whole turnkey PCBA services include schematic design, finding parts, putting them together, testing them, and handling logistics. This integrated approach makes it easier to deal with several suppliers and makes sure that communication stays open throughout the production cycle. More and more, companies that develop consumer electronics, industrial electronics, medical electronics, and automotive electronics are using turnkey solutions to save costs and get products to market faster. When procurement managers know all there is to know about the full turnkey strategy, they can make smart decisions that get the best quality and value for money.

Understanding Full Turnkey PCBA – From Concept to Completion

Full service PCBA is a completely integrated manufacturing process in which one company is in charge of everything from designing and buying the parts to putting them together and shipping the completed product. This seamless approach makes the product lifecycle easier, gets rid of risk, and speeds up the time it takes to get a product to market by a lot compared to the prior fragmented manufacturing methods.

Complete Service Integration Benefits

Some of the most important processes in the process include schematic design, managing the bill of materials, buying components, SMT and THT assembly, testing, and logistics. Customers of global B2B procurement services benefit from more efficient operations, easier communication, and fewer problems in the supply chain. Companies may make smart choices and optimize their procurement strategy to be ahead of the competition if they fully comprehend this end-to-end service.

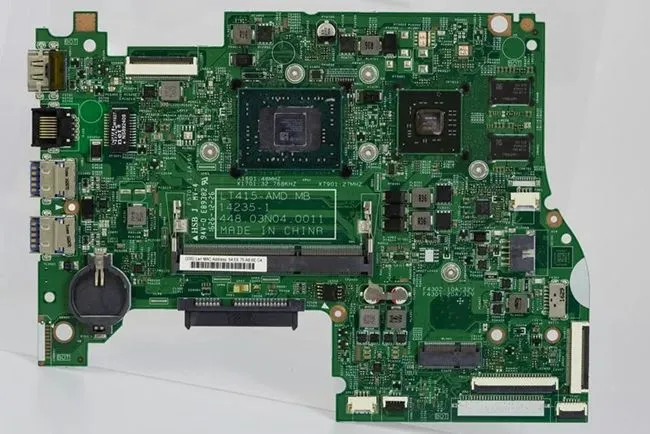

Modern turnkey PCBA providers employ cutting-edge technology like LDI laser exposure systems and vacuum lamination processes to make sure that manufacturing is accurate. These features make it feasible to construct intricate multi-layer boards with blind and buried vias that can handle high-density designs needed for 5G communications, industrial control systems, and medical devices. These boards may be anything from two to forty-eight layers thick.

Quality Assurance Throughout Manufacturing

The implementation of comprehensive quality control procedures occurs at each and every step of manufacturing. The use of cutting-edge inspection technologies such as X-ray analysis, automated optical inspection (AOI), and flying probe testing helps to guarantee that quality requirements are maintained consistently. In accordance with the requirements of IPC-6012 Class 3, these quality checkpoints keep defect rates at or below 0.2%, which is a substantial improvement above the industry average of less than 1%, especially in full turnkey PCBA solutions.

Comparing Full Turnkey PCBA with Other Assembly Models

Choosing the appropriate assembly model is essential to achieving both cost-effectiveness and success in the project. In terms of the extent of duty and the control that is exercised over the procurement procedures, full turnkey PCBA is quite different from partial turnkey and consignment models.

Service Model Distinctions

During complete turnkey agreements, suppliers are responsible for all parts of manufacturing, including the acquisition of components. On the other hand, partial turnkey arrangements may not include the responsibility of procuring components. There is an increased need for extra coordination and inventory management when using consignment models since the buyer is largely responsible for the procurement process. In addition, when turnkey PCBA is contrasted with EMS (Electronics Manufacturing Services), the differences in customization depth and service comprehensiveness are brought to light.

Cost and Timeline Optimization

Procurement managers are able to better match production strategies with budget limits and project schedules when they evaluate cost structures and lead times across a variety of models. In many cases, turnkey solutions provide improved cost-effectiveness by virtue of their bulk buying power and simplified logistics. This guarantees that resources are allocated in the most efficient manner possible while still keeping quality requirements.

Key Design and Manufacturing Considerations for Full Turnkey PCBA

Success in full turnkey PCBA depends heavily on design optimization and rigorous manufacturing quality control protocols. Early-stage design decisions significantly impact production efficiency and final product reliability.

Design for Manufacturing Excellence

Production yield and dependability are directly influenced by choices made during the early stages of design. These decisions include the concepts of DFM (Design for Manufacturing), the selection of components, and layout considerations. Expert engineering teams provide DFM optimization services that improve manufacturability while simultaneously lowering the risks associated with design and the price of the bill of materials. The use of these improvements helps to avoid expensive redesigns and ensures a seamless transition from the prototype to production.

Quality Control Integration

There are many quality checks in manufacturing, such as AOI, X-ray inspection, and functional testing. You need to deal with problems like parts becoming obsolete, supply chain problems, and following international standards before they happen. Clients who buy things from across the world need to make sure that their products meet certifications like IPC, ISO9001, IATF16949, and RoHS. This protects the safety of the products and makes sure that the rules are followed all the way through the supply chain.

How to Choose the Right Full Turnkey PCBA Supplier for Your Business?

When choosing a dependable turnkey PCBA provider, you should look at their technical skills, quality certifications, production capacity, and ability to be flexible with service. To make sure that partnerships work well, procurement professionals need to carefully consider a number of things.

Technical Capability Assessment

Procurement experts should carefully look at how well suppliers have delivered in the past, how well they can come up with new ideas, and how good their after-sales service is. For current electronics applications, advanced manufacturing capabilities are a must. These include high-density stack-up production, accurate impedance control (±7%), and trace spacing capabilities down to 3/3mil.

Partnership Evaluation Criteria

Checking MOQ (Minimum Order Quantity) needs, pricing models, and lead times makes ensuring that the project needs and cost goals are met. Global leaders in full turnkey PCBA manufacturing frequently generate trust and confidence by sharing clear customer case studies and third-party certifications. Working with experienced suppliers makes the supply chain more resilient and helps businesses meet expanding production needs.

Seamless Procurement: From Requesting Quotes to Delivery

To get a complete turnkey PCBA quickly, you need to follow an organized process that starts with clear RFQs (Request for Quotations) that spell out the specs and expectations. This methodical approach makes sure that the project goes well and is delivered on time.

Procurement Process Optimization

To get an accurate cost estimate, you need to take into account the pricing of the parts, the difficulty of putting them together, the testing needs, and the logistics. Ordering samples and managing contracts lower risks and make the terms of service clear before full-scale manufacturing starts. These first stages help everyone understand each other and set clear expectations for everyone involved.

Supply Chain Communication Excellence

Strong communication in the supply chain and using ERP systems make it much easier to monitor orders and make sure they arrive on time. These best practices assist procurement teams cut down on delays, keep inventory levels just right, and make sure that quality requirements are always met. This leads to easier partnerships and product launches that satisfy market needs.

Conclusion

Full turnkey PCBA solutions are the best choice for electronics makers that want to save time, money, and get the best quality. The integrated strategy makes the supply chain less complicated and improves quality control by using innovative production technology and strict testing procedures. Modern turnkey suppliers provide a whole range of services, from optimizing the original design to final delivery, and they do this with great accuracy on complicated multi-layer boards. Choosing the proper turnkey partner gives you access to sophisticated features, dependable delivery, and long-term relationship advantages that help your firm succeed in competitive electronics markets.

FAQ

Q1: What is the typical lead time for full turnkey PCBA projects?

A: Lead times depend on how complicated the project is and how big the order is. For most projects, they are between 5 and 15 business days. It may take longer for complicated multi-layer designs or specific parts. But accelerated services with 24/7 online assistance and 7-day manufacturing capability may cut down on regular delivery times for urgent needs by a lot.

Q2: How does full turnkey quality control differ from partial assembly approaches?

A: Full turnkey quality control means that there is more responsibility, such as checking components, making sure they fit together correctly, and doing thorough testing. This integrated strategy keeps quality standards higher, with failure rates below 0.2%. In contrast, fragmented models spread quality responsibilities across several providers.

Q3: What cost-saving potentials exist with turnkey PCBA solutions?

A: Turnkey solutions cut down on the expenses of storing goods, make it easier to buy things, and get rid of the costs of coordinating with various suppliers. When you buy a lot of things at once and use integrated logistics, you may save 15–25% on costs compared to using several suppliers for design, sourcing, and assembly services.

Partner with Ring PCB for Complete Turnkey Excellence

Ring PCB delivers comprehensive turnkey PCBA solutions that combine competitive pricing with exceptional manufacturing capabilities. Our expedited service offers 24/7 online support and continuous production 7 days a week, significantly outperforming standard delivery times for a more efficient delivery experience. We manufacture up to 48-layer multilayer circuit boards with advanced precision and maintain international ISO certifications including ISO9001 and IATF16949. As a leading full turnkey PCBA manufacturer, we integrate design optimization, component sourcing, precision assembly, and rigorous testing under one roof. Contact us at [email protected] to discover how our complete turnkey solutions can accelerate your product development timeline while ensuring exceptional quality standards.

References

1.Institute for Printed Circuits. "IPC Standards for Electronic Assembly Manufacturing." IPC Publications, 2023.

2.Electronics Manufacturing Services Industry Report. "Global PCBA Market Analysis and Trends." Market Research Institute, 2023.

3.Johnson, Michael R. "Design for Manufacturing in Electronics: Best Practices and Implementation." IEEE Transactions on Electronics Manufacturing, 2022.

4.International Organization for Standardization. "ISO 9001:2015 Quality Management Systems Requirements for Electronics Manufacturing." ISO Publications, 2023.

5.Chen, Linda K. "Supply Chain Optimization in Electronics Manufacturing: Turnkey vs. Consignment Models." Journal of Manufacturing Technology, 2022.

6.Williams, David A. "Advanced PCB Assembly Technologies: Multi-layer Design and Manufacturing Considerations." Electronics Engineering Quarterly, 2023.