Industrial and automotive grade PCBA is the best in electronic production, where dependability and performance combine under the toughest conditions. Automotive PCBA systems are the main parts of contemporary car electronics. They run everything from engine control units to complex driver aid systems. These complex assemblies need to keep working well for a long time, even when they are exposed to severe temperatures, vibrations, and electromagnetic interference. The difference between regular consumer electronics and automotive-grade solutions is that the latter are built to very high standards, use only the best materials, and go through a lot of testing to make sure they work perfectly every time, even when lives are on the line.

Understanding Automotive PCBA – Definition, Functions, and Key Technologies

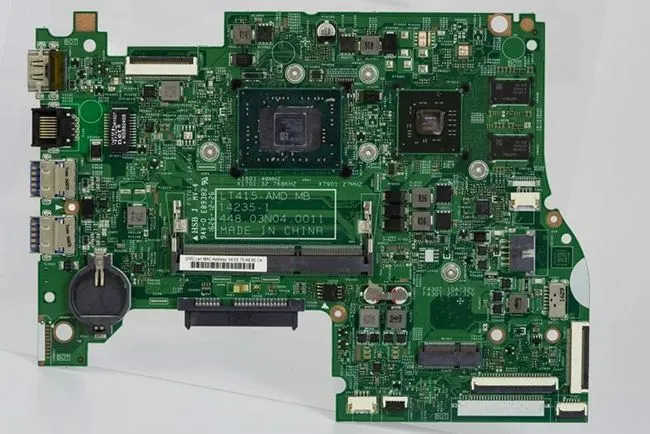

Automotive PCBA is a kind of printed circuit board assembly that is designed to fulfill the strict needs of vehicles. These assemblies put together many electronic parts on circuit boards that are designed to operate, monitor, and interact with vehicle systems. Modern car electronics are quite complicated, therefore PCBA solutions need to be able to handle high-speed data processing, real-time sensor feedback, and safety features that are very important at the same time.

Core Functions and Applications

Automotive PCBA is used in many important ways in modern cars that affect safety, performance, and the user experience. Engine control units use complex PCBA designs to govern fuel injection timing, ignition sequences, and emissions control systems with microsecond accuracy. High-performance PCBA assemblies are needed for advanced driver assistance systems to handle radar, camera, and lidar data in real time. This makes features like adaptive cruise control and automated emergency braking possible.

Another important use of automotive PCBA technology is in infotainment systems, where it makes it easy to connect, process multimedia, and control the user interface. These assemblies need to be able to work with a lot of different communication protocols and yet be able to work with other car systems that use electromagnetic waves. For wireless charging, GPS navigation, and smartphone connection to work together, PCBA designs need to be able to manage several frequency bands without interfering with each other.

Advanced Manufacturing Technologies

Surface-mount technology is the basis for current automotive PCBA production. It lets thousands of parts be placed exactly where they need to be, with tolerances measured in micrometers. Before functional testing starts, automated optical inspection devices check every solder connection and component location to make sure the assembly is flawless. Applying conformal coating adds an extra layer of protection against moisture, chemicals, and temperature extremes that are frequent in car conditions.

Thermal cycle tests participants put together assemblies that went through hundreds of temperature changes between -40°C and +125°C to make sure that the solder joints were strong and the parts were reliable. Vibration testing speeds up years of road conditions to make sure that every connection stays secure for the life of the vehicle. These thorough testing procedures set automobile PCBA apart from regular electronic assemblies.

Key Differences Between Automotive PCBA and Consumer Electronics PCBA

The difference between automotive and consumer electronics PCBA goes beyond only how they are used. It also includes variances in the materials, production techniques, and quality standards used. Automotive applications need components that can handle a wider range of temperatures, usually from -40°C to +150°C. Consumer electronics, on the other hand, have less strict requirements. For this temperature resistance, you need specific substrate materials, high-temperature solder alloys, and parts that are built to last in cars.

Material Quality and Environmental Resistance

Automotive PCBA uses high-quality substrates that are more stable in heat and stronger mechanically than those used in regular consumer electronics. Lead-free solder formulations designed for use in cars work better than other types of solder when the temperature changes. Strong encapsulation methods keep critical parts safe from moisture, salt spray, and chemicals in automobile fluids.

When choosing a substrate for automotive applications, you need to think carefully about its dielectric qualities, thermal expansion coefficients, and long-term durability under constant thermal stress. To keep the signal quality high during the long service life that is common in automotive applications, multi-layer stackups need accurate impedance management and reliable vias.

Certification Standards and Compliance

The IATF 16949 certification is the best way to show that an automotive quality management system is up to par. It requires full documentation, traceability, and mechanisms for continuous development. This certification makes sure that every part of making automotive PCBA satisfies the strict criteria set by car OEMs all over the globe. Automotive assembly must meet IPC-A-610 Class 3 acceptance requirements, which require the best quality of craftsmanship and inspection.

The cost-quality connection in automotive PCBA shows how important these applications are. Investing in high-quality materials and procedures up front leads to long-term dependability and lower warranty costs. Experienced automotive PCBA manufacturers know that to satisfy both delivery timelines and quality standards, they need to be able to manage their supply chains and organize their manufacturing in a highly complex way.

How to Choose the Best Automotive PCBA Manufacturer – Decision-Making Criteria

When choosing an automotive PCBA manufacturer, you need to do a thorough assessment that takes into account their technical skills, quality systems, and ability to work with your company. Because automotive electronics are so complicated, partners need to know both the technical needs and the business challenges that automotive suppliers face. To have successful collaborations, firms need to carefully look at each other's production capabilities, quality certifications, and cultural fit.

Quality Certifications and Production Capacity

ISO/TS 16949 certification is the first step in qualifying an automotive supplier. It shows that the supplier is committed to following automotive quality management standards. IPC standards compliance makes sure that the way PCBA is put together meets international standards for quality and dependability. To make sure that partnerships can expand over time, evaluations of production capacity must take into account both present volume needs and future growth estimates.

Quality control systems need to include full documentation and traceability features that may help with car recalls if they are needed. The use of statistical process control shows that the company is dedicated to making things better all the time and avoiding defects, not just finding them.

Supply Chain Management and Flexibility

To handle the complicated connections between OEMs, tier-one suppliers, and component manufacturers, automotive supply chains need to be able to coordinate and communicate very well. Policies for minimum order quantities must match the timetables for making cars and keep costs low for both prototype and production numbers. Flexible manufacturing capabilities make it possible to quickly respond to changes in design and the need to scale up output.

Vendor audits make it clear how well a company can make things, how good its quality procedures are, and how stable its finances are. Factory inspections show the real production environment and the company's dedication to quality that may not be clear from just looking at the paperwork. Support after the sale becomes very important when a product is first released or when there are problems with quality throughout manufacture.

Enhancing Reliability and Performance of Automotive PCBA – Technical Best Practices

To improve the dependability of automotive PCBA, a systematic strategy is needed that looks at possible failure modes before they happen in real-world situations. Failures in solder joints are one of the most prevalent reliability issues, especially in automotive situations where temperatures change quickly. When parts with various thermal expansion coefficients are put together, managing thermal stress becomes very important.

Design for Reliability Principles

Optimized trace design reduce problems with signal integrity and provide power distribution networks enough current carrying capacity. Stress relief measures, such flexible sections and smart arrangement of parts, lower the number of mechanical stress concentration locations that might cause fatigue failures. Choosing and applying a strong conformal coating will defend against environmental contamination for a long time without getting in the way of thermal management.

From the very beginning of the design process, design for manufacturing and design for test concepts must be combined. This will make sure that quality can be checked at every level of manufacture. When choosing parts, you should put automotive-qualified parts with the right temperature ratings and long-term availability assurances at the top of your list.

Testing and Validation Protocols

Life in a Very Short Time Testing subject assemblies under stress circumstances that go beyond normal operating limits to find possible failure mechanisms in a shorter amount of time. Environmental endurance testing checks how well a car works when it is exposed to chemicals, salt spray, and humidity, which are all common in car servicing facilities. Testing for firmware compatibility makes ensuring that software upgrades can be made without making the system less reliable.

Automotive OEM testing procedures are the best way to check the strength of a design and the quality of its manufacture in the real world. These thorough validation methods enable B2B customers see how valuable it is to have automotive PCBA design and production done correctly.

Ring PCB: Your Trusted Partner for Automotive PCBA Excellence

Ring PCB is a well-known leader in PCBA solutions for industrial and automotive use. Global OEMs and distributors trust them because they expect the best in every part of electronic production. Our broad range of manufacturing services includes everything from quick prototype to mass production, all backed by cutting-edge quality assurance methods and full conformity with worldwide automobile certification requirements. We know that automotive electronics need more than just technical skills; they need a partner that is just as dedicated to quality, dependability, and customer success as you are.

Advanced Manufacturing Capabilities

Our modern production plant uses the latest technology to make PCBA solutions that are more precise than what is required by the industry. We make high-density circuit boards with 2 to 48 layers with blind and buried vias. These boards may have traces and spaces as small as 3/3mil. Our impedance control maintains a tolerance of ±7%, which makes our solutions excellent for 5G applications, industrial control systems, medical devices, and automotive electronics that need precise signal integrity.

Our smart manufacturing method includes LDI laser exposure equipment, vacuum lamination technologies, and flying probe testing capabilities to make sure that IPC-6012 Class 3 standards are met. This all-in-one method lets us maintain the highest quality standards while yet meeting your project's deadlines with competitive lead times.

Comprehensive Quality Assurance

Our strategy for making automotive PCBA is based on quality, which we achieve via our triple quality assurance approach that includes AOI, impedance testing, and thermal cycling validation. Our failure rate is always around 0.2%, which is far better than the industry norm of less than 1%. This level of performance shows that we are committed to delivering goods with no defects and keeping our customers happy for a long time.

Our vertical integration method gives us full control over the supply chain, from getting raw materials to testing and delivering the finished product. This level of monitoring lets us maintain the same level of quality while also giving automotive clients the flexibility and responsiveness they need in today's fast-paced industry.

Conclusion

Industrial and automotive-grade PCBA is an important part of the technology that makes the complex electronic systems that define how well a car performs, how safe it is, and how enjoyable it is to use. The difference between automotive and consumer electronics PCBA goes beyond only how they are used. It also includes variances in materials, production methods, quality requirements, and reliability testing. To successfully buy automotive PCBA, you need to carefully choose the right manufacturer based on their technical skills, quality certifications, and ability to work with you. Ring PCB is the best partner for your automotive electronics needs since we are dedicated to making high-quality automotive PCBA and have sophisticated skills and quality processes in place.

FAQ

Q1: What makes automotive PCBA different from standard electronic assemblies?

A: Automotive PCBA needs unique materials that can handle a wide range of temperatures (-40°C to +150°C), are more resistant to the environment, and meet strict automotive quality requirements like IATF 16949. To make sure they work reliably for the whole life of the vehicle, these assemblies go through a lot of testing, such as temperature cycling, vibration testing, and environmental endurance validation.

Q2: How long are typical lead times for automotive PCBA orders?

A: The lead times depend on how complicated and how many there are, but they usually range from 2 to 4 weeks for prototypes and 4 to 8 weeks for production numbers. Ring PCB's accelerated service includes 24/7 online assistance and the ability to keep making products all the time. This cuts down on usual delivery times while still meeting quality requirements.

Q3: What certifications should I look for in an automotive PCBA manufacturer?

A: IATF 16949 for automotive quality management, ISO 9001 for general quality systems, and IPC standards conformance for assembly workmanship are all important certifications. RoHS compliance and UL recognition are two other certifications that show a company's dedication to quality and ability to follow the rules.

Partner with Ring PCB for Superior Automotive PCBA Solutions

Are you ready to improve the electronics in your car with trustworthy, high-performance PCBA solutions? Ring PCB uses the latest manufacturing technology and meets automotive-grade quality requirements to provide you great results on your projects. Our products are economically priced and use multilayer circuit boards with up to 48 layers. They are also supported by worldwide ISO certifications and a full quality assurance program. We provide speedier delivery times that keep your projects on track thanks to 24/7 online assistance and 7-day-a-week manufacturing. Contact us at [email protected] to discuss your automotive PCBA requirements with our experienced engineering team and discover why leading manufacturers choose Ring PCB as their trusted automotive PCBA supplier.

References

1. Smith, J.A., "Automotive Electronics Reliability Standards and Testing Methodologies," Journal of Automotive Engineering Technology, Vol. 45, No. 3, 2023.

2. Chen, L.M., "Advanced PCBA Manufacturing Techniques for Automotive Applications," International Conference on Electronic Manufacturing Processes, 2023.

3. Rodriguez, M.K., "Quality Management Systems in Automotive Electronics Manufacturing," Automotive Quality Engineering Quarterly, Vol. 28, No. 2, 2023.

4. Thompson, R.D., "Thermal Management and Reliability Enhancement in Automotive PCBA Design," IEEE Transactions on Automotive Electronics, Vol. 15, No. 4, 2023.

5. Williams, S.P., "Supply Chain Management Best Practices for Automotive Electronics Procurement," Journal of Automotive Supply Chain Management, Vol. 12, No. 1, 2024.

6. Anderson, K.L., "Emerging Technologies in Automotive PCBA Manufacturing and Testing," Society of Automotive Engineers Technical Paper Series, Paper No. 2024-01-0156, 2024.