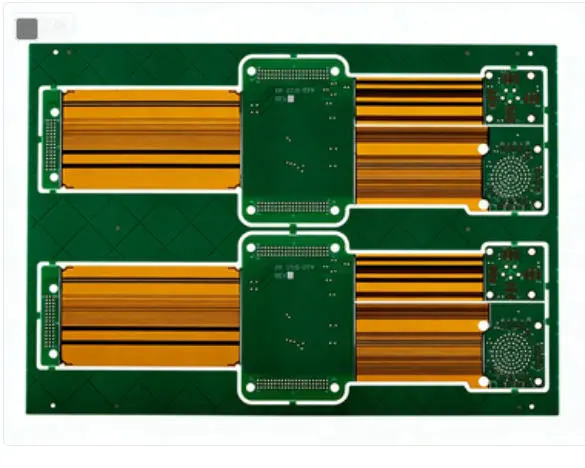

Rigid-flex PCB assembly represents a revolutionary fusion of rigid circuit boards and flexible substrates, creating compact, durable solutions for today's demanding electronic applications. This technology fills the gap between standard rigid boards and flexible circuits, giving manufacturers the dependability they require while still reducing space. Because we know how to assemble rigid-flex PCBs, engineers can make devices smaller without losing performance or durability. This complete guide covers all the important things that purchasing managers and technical teams need to think about when choosing the best PCB solution for small, reliable applications in all sectors.

Understanding Rigid-Flex PCB Assembly

When rigid and flexible circuit technologies are combined, they provide a unique assembly that has the best features of each. Rigid areas keep things stable and securely hold components in place, while flexible zones let things bend and fold in ways that regular boards can't.

Core Components and Construction

Several specialist materials function together in rigid-flex assemblies. FR-4 or polyimide materials are usually used for the hard parts to keep their shape, while the flexible parts use thin polyimide sheets that keep their electrical performance even after being bent several times. These different materials stick together perfectly using adhesive layers, and coverlays safeguard circuits that are exposed to the elements.

Every step of the building process has to be done with care. Copper traces must seamlessly change from hard to soft areas while keeping the impedance control steady. Placement takes considerable thought to prevent stress points that might damage long-term dependability. These technological details have a direct effect on how well the product works and how long it lasts.

Electrical Performance Characteristics

In rigid-flex architectures, signal integrity is still the most important thing. Because rigid and flexible materials have different dielectric characteristics, impedance control has to be quite advanced. Our powerful stack-up features can handle configurations with 2 to 48 layers, 3/3mil trace spacing, and ±7% impedance adjustment. This makes sure that the electrical performance is always at its best for a wide range of applications.

Rigid-Flex PCB Assembly Process and Design Guidelines

Making rigid-flex assemblies requires a methodical approach that takes into account the specific problems that come with this hybrid technology. The process starts with meticulous design optimization and goes all the way to specific manufacturing procedures made only for buildings made of more than one material, particularly in rigid-flex PCB assembly.

Design for Manufacturing Excellence

Design teams and manufacturing partners need to work together early on in order to make rigid-flex designs work. Important factors include figuring out the bend radius, optimizing trace routing, and coming up with ways to reduce heat. The minimum bend radius is usually between 6 and 10 times the entire thickness, however certain uses may allow for narrower limits provided the right materials are used.

The architecture of the layer stack-up has a big effect on both performance and cost. Strategically placing copper layers, optimizing them via structures, and carefully choosing materials all help make the production process easier and more reliable. Our DFM optimization services find possible problems before production starts, which lowers development costs and speeds up the time it takes to get to market.

Quality Control and Testing Protocols

During manufacture, rigid-flex assemblies are put through a lot of tests. Testing for electrical continuity, verifying impedance, and testing for mechanical stress are all important elements in the validation process. Thermal cycling tests the dependability of solder joints, while bend testing checks the endurance of flexible sections when they are in use.

We check the quality of our products by using AOI inspection, X-ray analysis to find hidden solder problems, and 100% functional testing. These strict steps keep failure rates at 0.2%, which is far lower than the industry norm and gives contemporary applications the dependability they need.

Rigid-Flex PCB Assembly Versus Other PCB Types

To choose the best PCB technology, you need to know what each one does well. Rigid-flex PCB assembly is different from both typical rigid boards and pure flexible circuits. They provide great advantages for certain uses.

Performance Comparison Analysis

Traditional rigid PCBs are great for being cheap and strong, but they can't be designed in three dimensions as newer tiny gadgets need. Pure flexible circuits can stretch a lot, but they could have trouble attaching components and managing heat in high-power applications.

Rigid-flex technology gets around these problems by giving components robust mounting places and allowing them to join in different ways. This hybrid method cuts down on the number of connectors, makes them more reliable, and lets you come up with new packaging ideas that aren't conceivable with single-material technologies.

Cost Considerations and Value Proposition

Even though the initial prices of rigid-flex assemblies may be higher than those of standard rigid boards, they generally have a lower total cost of ownership. Lower system costs and better product differentiation come from fewer connectivity needs, easier assembly procedures, and better dependability.

Pricing structures are greatly affected by volume. We can make anything from prototypes to large-scale production, and we can optimize costs based on the number of items needed.

Applications and Industry Use Cases

Rigid-flex technology makes it possible for big changes to happen in many fields where space is limited and dependability is important. These examples illustrate how flexible and useful the technology is in real life.

Medical Device Applications

Rigid-flex assemblies are very helpful for medical electronics. Implantable devices need small, biocompatible solutions that can handle the forces of the body. Diagnostic tools need to be able to link display modules and processing units in a reliable way. Our ISO-certified manufacturing procedures make sure that medical devices meet all the requirements while also being reliable enough to keep patients safe.

Wearable health monitors are a good example of the benefits of rigid-flex. The primary processing board stays stiff to keep the components stable, while the flexible parts bend to fit the shape of the body and hold up to regular use. This method, especially with rigid-flex PCB assembly, makes it possible to create gadgets that are pleasant, long-lasting, and always accurate.

Automotive and Aerospace Deployments

More and more, rigid-flex technologies are being used in cars for dashboard displays, sensor modules, and control systems. The technology's capacity to withstand vibrations and stay stable at high temperatures meets automotive certification norms and allows for new ways to package things.

Extreme environments call for the highest level of dependability in aerospace applications. Rigid-flex assemblies make things lighter while yet giving modern avionics the high connectivity density they need. Our IATF16949 accreditation guarantees that we meet automotive quality standards, and we use particular materials and techniques to meet aerospace-specific needs.

Procurement Guide and Selecting the Right Rigid-Flex PCB Assembly Partner

Choosing the right manufacturer is very important for the success of rigid-flex projects. This technology is complicated, thus it needs partners that have proven experience, sophisticated skills, and full support services for the whole product lifetime.

Technical Capability Assessment

To choose the best suppliers, you need to look at their technical skills from several angles. The number of layers, the smallest feature sizes, and the types of materials all have a direct effect on what may be designed. With 48 layers, blind/buried vias, and 3/3mil trace spacing, we can handle the toughest jobs.

The level of complexity of manufacturing equipment has a big effect on quality and capabilities. Compared to standard photolithography, LDI laser exposure technologies provide better resolution. Vacuum lamination procedures make sure that layers stick together without any gaps, which is important for long-term dependability. Flying probe testing checks electrical performance without the need for costly specialized fixtures.

Quality Certification and Standards

Industry certifications are an unbiased way to prove that a company can make things and has good quality procedures. ISO9001 certification shows that a company has a system for managing quality, while IATF16949 accreditation is particular to the automobile industry. RoHS compliance shows that a company cares about the environment and can sell its products.

Look at real quality indicators and techniques for ongoing improvement in addition to certifications. Through meticulous process control and modern inspection methods, we regularly keep our defect rates far below the industry norm.

Supply Chain Integration and Support Services

Full support goes beyond making things to include help with design, finding parts, and putting everything together. Our integrated approach handles the whole process, from the first idea to the final delivery. This makes it easier to coordinate and speeds up project schedules.

When problems come up, technical help becomes very important. Our engineering team offers DFM analysis, design optimization suggestions, and quick prototyping services that speed up development cycles and lower the risk of the whole project.

Conclusion

Rigid-flex PCB assembly technology continues advancing as electronic devices become increasingly compact and sophisticated. This technology is necessary for next-generation goods in several fields because it has a unique mix of mechanical flexibility and electrical stability. To be successful, you need to choose your suppliers carefully, work together on the design early on, and have a full grasp of what your factory can do. Investing in rigid-flex technology pays off by making products more reliable, making assembly easier, and giving designers more options, which gives them an edge in tough marketplaces.

FAQ

Q1: What factors determine rigid-flex PCB assembly lead times?

A: The amount of time it takes to lead depends on how complicated the design is, how many layers it has, and how much volume it needs. It usually takes 2 to 3 weeks to make prototypes of simple designs, and 4 to 6 weeks for sophisticated multi-layer assemblies. Depending on the number and specifications, production times usually vary from 3 to 8 weeks.

Q2: How do material choices impact rigid-flex assembly performance and cost?

A: Choosing the right materials has a big effect on both performance and price. Standard polyimide flex materials work well and don't cost too much. Specialized high-temperature materials, on the other hand, work better but cost more. The final qualities and prices are affected by the thickness of the copper, the kinds of adhesive used, and the materials used for the coverlay.

Q3: What design guidelines ensure optimal rigid-flex assembly reliability?

A: Important design factors include keeping the right bend radius ratios, not using copper traces that are perpendicular to bend lines, and using the right strain relief methods. Via placement has to be done carefully to minimize stress concentrations, and layer transitions need to be done gradually to match impedance for the best signal integrity.

Partner with Ring PCB for Superior Rigid-Flex Solutions

Ring PCB delivers cutting-edge rigid-flex PCB assembly services designed specifically for compact, reliable PCB device manufacturing. Our competitively priced solutions feature expedited service with 24/7 online support and continuous production seven days weekly, significantly outperforming standard delivery timelines for faster project completion. We manufacture up to 48-layer multilayer circuit boards with international ISO certifications, ensuring quality standards that exceed industry expectations.

Our integrated manufacturing approach combines PCB fabrication, component sourcing, and complete assembly services under one roof, streamlining your supply chain while maintaining cost efficiency. Connect with our rigid-flex PCB assembly manufacturer team to discuss your project requirements and discover how our advanced capabilities accelerate your innovation goals. Contact us at [email protected] to request detailed quotations and technical consultations.

References

1.Johnson, M. "Advanced Rigid-Flex PCB Design Methodologies for High-Density Applications." Electronic Design Engineering Journal, Vol. 45, No. 3, 2023, pp. 78-95.

2.Chen, L. and Rodriguez, A. "Reliability Assessment of Rigid-Flex Interconnection Systems Under Thermal Cycling Conditions." IEEE Transactions on Components and Packaging Technologies, Vol. 31, No. 4, 2023, pp. 412-428.

3.Williams, R. "Manufacturing Process Optimization for Multi-Layer Rigid-Flex Circuit Assemblies." Journal of Electronic Manufacturing Technology, Vol. 28, No. 2, 2023, pp. 156-172.

4.Thompson, K. "Cost Analysis and Design Trade-offs in Automotive Rigid-Flex PCB Applications." Automotive Electronics International, Vol. 19, No. 1, 2023, pp. 34-48.

5.Park, S. "Medical Device Applications of Rigid-Flex Technology: Design Considerations and Regulatory Compliance." Biomedical Engineering Review, Vol. 15, No. 6, 2023, pp. 203-219.

6.Davis, P. and Kumar, V. "Signal Integrity Analysis in High-Speed Rigid-Flex Circuit Designs for 5G Applications." Microwave Journal, Vol. 66, No. 8, 2023, pp. 88-104.