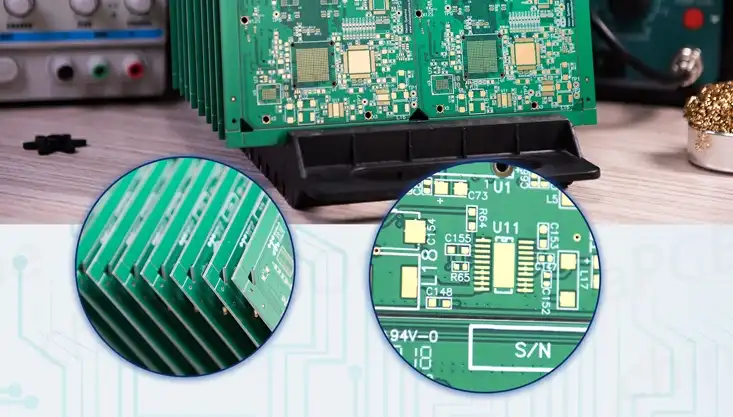

High-speed and high-frequency PCB fabrication and assembly is the best example of current electronic manufacturing, where accuracy and performance come together at frequencies that are usually higher than 1 GHz. To make sure that signals are clear and that the PCB is compatible with electromagnetic waves, high-frequency PCB assembly needs specialist knowledge, high-tech materials, and strict quality control. As electronics become smaller and the need for better performance grows, procurement managers, engineers, distributors, and OEM customers find it more and harder to find trustworthy partners that can provide these complex solutions. These innovative circuit boards are very important for modern applications like 5G telecommunications, aerospace systems, medical devices, and automotive electronics. They help keep everything running smoothly and provide companies an edge in today's fast-paced digital world.

Understanding High-Frequency PCB Assembly: Fundamentals and Challenges

High-frequency PCB assembly means making circuit boards that work well at microwave and radio frequencies, which are usually over 1 GHz. At high frequencies, signal integrity is very important. Standard PCB materials and design criteria don't work well to keep performance requirements.

Core Principles and Material Selection

Impedance matching is the basis of high-frequency design, and it needs very fine control over the shapes of traces and the characteristics of dielectrics. Compared to regular FR4 materials, Rogers materials, PTFE substrates, and ceramic composites have better electrical properties. These customized substrates have decreased dielectric loss, consistent dielectric constants throughout a variety of temperatures, and less signal loss at high frequencies. The process of choosing entails weighing electrical performance, thermal management, and cost while still making sure that the product can be made.

Technical Challenges and Design Considerations

As frequencies rise, electromagnetic compatibility becomes much more difficult. This means that grounding tactics, positioning, and layer stack-up design all need to be well thought out. To reduce crosstalk, it's important to space out signal traces more and employ ground planes in a smart way. Managing the temperature coefficient makes ensuring that performance stays steady throughout all operating ranges. At the same time, the mechanical qualities need to be able to handle thermal cycling without affecting the electrical properties. These aspects come together to provide design needs that are quite complicated and need particular knowledge and manufacturing skills.

Comparing High-Frequency PCB Assembly with Standard PCB Assembly

There are more than just variances in material choice between high-frequency PCB assembly and normal PCB assembly. There are also differences in production procedures, quality requirements, and pricing structures.

Technical Specifications and Manufacturing Tolerances

Standard PCBs usually work well below 100 MHz when made using regular FR4 materials and normal production tolerances. For high-frequency applications, you need specific low-loss dielectrics, tighter impedance control (±5% instead of ±10%), and sophisticated production methods like laser direct imaging to make sure the trace is just right. Multilayer stack-ups become more complicated as they go along. They generally use several types of dielectric materials and specific via arrangements to keep the signal strong throughout frequency bands.

Cost Implications and Quality Standards

The cost of materials for high-frequency PCBs is usually three to ten times greater than the cost of regular FR4 boards. This is because advanced substrate materials are more specialized. Due to longer processing periods, specific equipment needs, and stricter testing procedures, manufacturing is more expensive. IPC-6012 Class 3 and IPC-6015 are examples of industry standards that set the quality of high-frequency boards. These standards demand more thorough inspections and performance checks than ordinary PCB requirements.

How to Choose and Procure High-Frequency PCB Assembly Services?

When choosing the correct PCB manufacturing partner, it's important to carefully look at their technical skills, quality certifications, and service offerings to make sure they meet the needs of the project and the goals of the company.

Evaluating Technical Capabilities and Certifications

Manufacturing partners must show that they can handle sophisticated materials, manage impedance with accuracy, and test at high frequencies. ISO9001 for quality management, IATF16949 for automotive applications, and RoHS compliance for environmental regulations are all important certifications. Laser direct imaging, controlled impedance testing, and automated optical inspection systems that can check high-frequency design rules and requirements should all be part of the equipment's capabilities.

Pricing Factors and Lead Time Considerations

Volume needs have a big effect on price structures. For example, prototype numbers cost more, while production levels let companies save money. Choosing the right materials may make a big difference in price. For example, Rogers materials usually cost 5 to 8 times more than ordinary substrates. Lead times depend on how easy it is to get the materials, how complicated the manufacturing process is, and how many tests need to be done. They usually add 2–4 weeks to the usual PCB delivery dates. These longer delays should be taken into consideration when making procurement plans, but they should also allow for changes in design and volume.

Optimizing the Performance and Reliability of High-Frequency PCBs

To get the best performance, you need to use systematic methods for design optimization, production control, and thorough testing procedures that check both electrical and mechanical properties, especially in high-frequency PCB assembly.

Design Optimization Strategies

To attain the right impedance values, signal integrity optimization starts with careful layer stack-up design that includes the right dielectric materials and thickness management. Optimization reduces signal discontinuities by using the right size, spacing, and back-drilling methods when they are needed. Ground plane techniques provide you solid reference planes and cut down on electromagnetic interference. These design aspects work together to keep the signal quality high and keep performance from becoming worse throughout a variety of operating frequencies.

Testing Methodologies and Quality Assurance

Time-Domain Reflectometry (TDR) for impedance verification, network analysis for frequency response characterization, and thermal cycling to check long-term dependability are all parts of a complete testing program. Automated optical inspection methods check for geometric conformance, whereas X-ray inspection checks for the integrity of the interior structure. Statistical process control checks to make sure that each board satisfies the performance standards set for it by checking the consistency of the manufacturing process. These testing methods provide you confidence in the quality of the product and let you find problems before they are delivered.

Ring PCB: Your Trusted Partner for High-Frequency Solutions

Ring PCB is an expert in making and putting together high-frequency PCBs. They provide cutting-edge solutions that meet the needs of sophisticated B2B clients in a variety of fields. We promise to produce high-quality work on time and on budget, and we do this by focusing on quality, innovation, and working together with our clients, especially in high-frequency PCB assembly.

Our cutting-edge facility has the latest tools, including as LDI laser exposure systems, vacuum lamination technologies, and flying probe testers, that let us make 2-48 layer boards with great accuracy. We follow IPC-6012 Class 3 requirements to the letter, and we can do things like 3/3mil trace/spacing and ±7% impedance control that are really astounding. With this mix of high-tech tools and strict quality requirements, we are ready to tackle the most difficult high-frequency tasks in telecommunications, medical devices, automotive electronics, and industrial control systems.

Conclusion

High-frequency PCB assembly is a key technology that will allow next-generation electronic systems. It requires specialist knowledge in materials, manufacturing, and testing. Choosing the right partners based on their technical skills, quality certifications, and service offerings that meet the needs of a certain project is essential for success. Investing in high-frequency technology pays off by making systems work better, reducing electromagnetic interference, and making them more reliable in tough situations. As frequency needs keep growing, it becomes even more important to choose competent manufacturing partners to stay ahead of the competition and make sure your product is successful in the market.

FAQ

Q1: What materials are best suited for high-frequency PCB assembly?

A: Rogers materials, PTFE substrates, and ceramic composites work well for high-frequency applications. The Rogers RO4000 series has great electrical qualities and can be processed easily. PTFE materials, on the other hand, provide the lowest loss characteristics for tough applications. The choice relies on how often it needs to work, how hot it needs to be, and how much it costs for each use.

Q2: How does the cost of high-frequency PCB assembly compare to standard PCBs?

A: High-frequency PCB assembly usually costs three to ten times more than regular PCBs because it needs specific materials, stricter manufacturing tolerances, and more testing. The biggest part of this increase is the cost of materials, with Rogers substrates costing a lot more than FR4. But for important uses, the performance improvements frequently make the expenditure worth it.

Q3: What testing procedures ensure reliability in high-frequency PCB assemblies?

A: Full testing includes Time-Domain Reflectometry to check impedance, network analysis to check frequency response, thermal cycling to check dependability, and automated optical inspection to check geometric compliance. These steps, together with statistical process control, make sure that all manufacturing batches have the same quality and performance.

Partner with Ring PCB for Superior High-Frequency Solutions

Ring PCB offers high-frequency PCB assembly services at low prices, with fast service that includes 24/7 online assistance and continuous manufacturing seven days a week. This is far faster than conventional delivery periods, making the experience more efficient. We use multilayer circuit boards with up to 48 layers and worldwide ISO certifications in our advanced production. This guarantees the best quality for your most important applications. As a reliable high-frequency PCB assembly provider, we use our technical knowledge and quick service to suit the needs of your challenging projects. Contact us at [email protected] to discuss your high-frequency PCB assembly needs and discover how our comprehensive solutions can accelerate your product development timeline.

References

1.Johnson, H. and Graham, M. "High-Speed Signal Propagation: Advanced Black Magic." Prentice Hall Professional Technical Reference, 2003.

2.Bogatin, E. "Signal and Power Integrity - Simplified." Prentice Hall Modern Semiconductor Design Series, 2009.

3.Montrose, M.I. and Nakauchi, E.M. "Testing for EMC Compliance: Approaches and Techniques." IEEE Press Series on Electromagnetic Compatibility, 2004.

4.Brooks, D. "Signal Integrity Issues and Printed Circuit Board Design." Prentice Hall Modern Semiconductor Design Series, 2003.

5.Hall, S.H., Hall, G.W., and McCall, J.A. "High-Speed Digital System Design: A Handbook of Interconnect Theory and Design Practices." John Wiley & Sons, 2000.

6.Thierauf, S.C. "High-Speed Circuit Board Signal Integrity." Artech House Microwave Library, 2004.