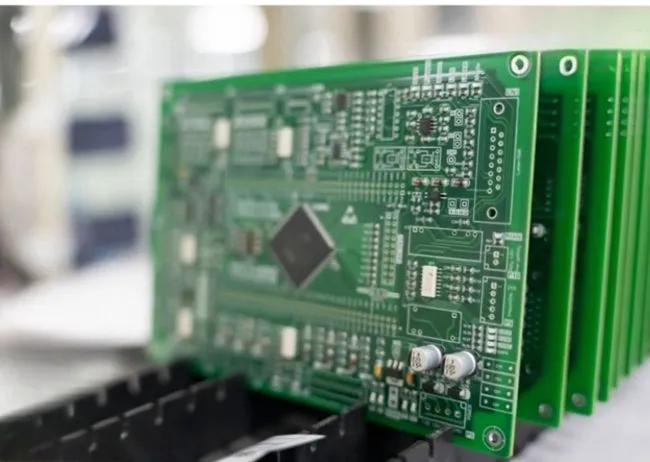

Exporting power supply PCBA from China has become a smart way for electronics companies throughout the world to get what they need without spending too much money or giving up quality. Purchasing managers from many sectors are drawn to China's strong manufacturing environment because it provides sophisticated PCB assembly, strict quality standards, and reasonable price. Buyers may make smart choices when getting power management solutions from Chinese providers if they know about export restrictions, how to shorten lead times, and the minimum purchase quantities. This in-depth study looks at the most important aspects that affect effective procurement while also pointing out ways to improve supply chain efficiency and follow the rules.

Understanding Export Requirements for Power Supply PCBA from China

If you want to export power supply assemblies, you need to know a lot about international compliance requirements and how to fill out the right paperwork. To make sure their products are accepted in the global market and can pass customs quickly, Chinese manufacturers must follow a number of certification procedures.

Essential Certification Standards and Compliance

Power supply PCBA exports must meet strict international safety and quality requirements. The CE label makes sure that a product meets European market standards, while the RoHS certification makes sure that electronic parts don't contain dangerous compounds. UL certification is very important for North American markets, especially for industrial and medical uses where safety is the most important thing. ISO 9001 quality management systems show that production is consistent, and IATF 16949 accreditation meets the needs of the automobile sector. Together, these certificates build trust and open up markets in many different parts of the world.

Chinese firms are putting more money on full certification portfolios to keep up with changing rules and regulations. Advanced facilities use IPC-6012 Class 3 requirements for high-reliability applications. This makes sure that exported assemblies fulfill strict performance standards. Third-party auditing services check production processes, which gives overseas customers more confidence that the quality will stay the same and that the company will follow the rules.

Documentation Requirements for Seamless Export Processing

To have successful export operations, you need to carefully handle all of the paperwork that goes along with them, such as technical standards, quality certificates, and shipping rules. Commercial invoices, packing lists, and bills of lading are the most important parts of export paperwork. Certificates of origin help make trade agreements more favorable. Material safety data sheets (MSDS) talk about the chemical makeup of things, which is especially significant for assemblies that include unusual parts or materials.

Export paperwork goes beyond only shipping regulations to include documents of technological compliance. Test reports, quality inspection certifications, and traceability documents help with customs clearance and provide purchasers full proof that the goods is real. Digital documentation solutions make the export process easier by allowing for real-time tracking and cutting down on administrative delays that might affect delivery times.

Lead Time Factors and How to Effectively Manage Them

The time it takes to make power management assemblies depends on a number of factors, such as how complicated the design is and how easy it is to get the materials. When procurement teams know about these things, they can make realistic timeframes and come up with ways to make the most of their schedules.

Production Stages and Timeline Optimization

The process of making power supply PCBA is made up of many steps that all affect the total lead time. For normal standards, PCB production usually takes 7 to 10 days. For more complicated multilayer designs with impedance control, it might take 14 to 21 days. Component sourcing happens at the same time as PCB fabrication. Common parts are easy to get, while specialty parts may take 2 to 4 weeks to get.

Putting together parts using surface mount technology (SMT), inserting through-hole components, and final assembly usually takes 3 to 5 days, depending on how complicated and large the project is. Functional testing, which includes checking the electrical system and burn-in tests, adds 2–3 days to make sure quality requirements are met. Packaging and the last inspection finish the production cycle, getting things ready to be sent abroad.

Turnkey manufacturing services save lead times by a lot by putting all of the different steps under one management. Integrated vendors that handle both PCB manufacturing and assembly cut down on delays in coordination while keeping quality consistent at all stages of production.

Strategic Approaches for Lead Time Reduction

A thorough design review and manufacturability study are the first steps in managing lead time well. Design for Manufacturing (DFM) consultations identify possible production problems early in the development process, which allows for design changes that make manufacturing more efficient. Standardized component selection makes sourcing easier while still meeting performance needs.

Strategic material planning helps inventory management tactics make delivery schedules even better. Suppliers that keep extra stock of popular parts can quickly meet urgent needs, and planning based on forecasts lets them buy materials ahead of time. Communication methods that set up frequent updates on progress make sure that everyone knows what's going on throughout the production process. This lets purchasers plan for any delays and change project timeframes as needed.

Understanding MOQ (Minimum Order Quantity) and Its Impact on Procurement

Minimum order numbers are basic economic rules that control how efficiently and cost-effectively PCBA is made. Buyers may find a balance between getting what they need and keeping costs down by knowing how MOQ arrangements work.

Economic Factors Influencing MOQ Structures

MOQ requirements take into account the expenses of setting up a factory, the quantity of material batches, and how efficient production is. To keep costs down, PCB fabrication tooling costs require a minimum number of panels. On the other hand, when buying components, manufacturers often have packaging requirements that affect the minimum number of orders. Setting up for assembly, which includes programming, preparing tools, and checking quality, produces fixed expenses that are better spread out across bigger production runs.

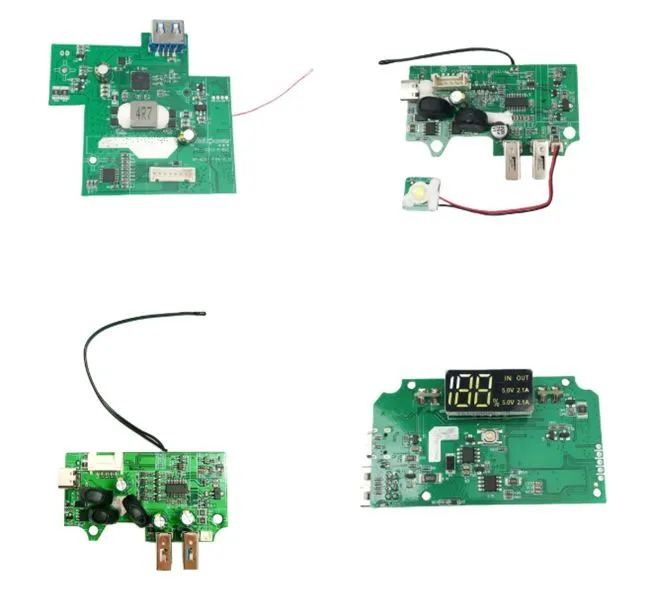

Standard power supply designs usually have lower minimum order quantity (MOQ) requirements since they are easier to customize and have well-established production processes. Custom assemblies that use unusual parts or have specific mechanical needs may need larger minimum numbers to make the cost of tools and setup worth it. Buyers may make smart choices about how much customisation and volume they want to commit to by understanding these economic links.

Negotiation Strategies for MOQ Flexibility

Strategic MOQ negotiation meets different buying demands while yet making sure suppliers make money. Suppliers typically provide extra attention to prototype quantities, accepting lesser amounts at higher prices to help customers improve their products. Long-term partnership agreements may let you lower your minimum order quantity (MOQ) in return for stable volume forecasts and commitment.

Smaller customers might get better MOQ conditions by combining orders or working with distributors to form partnerships. Some suppliers have inventory strategies that let them make conventional items in large numbers and then call them off when required. This gives them flexibility while keeping costs low. These methods make it possible to have high-quality production without having to spend a lot of money on inventory.

Comparing Power Supply PCBA from Chinese Manufacturers to Global Alternatives

Chinese power supply assembly manufacturers have evolved significantly, now offering quality standards and technical capabilities in Power supply PCBA that compete effectively with established global suppliers. This transformation reflects substantial investments in technology, quality systems, and technical expertise.

Quality Standards and Technical Capabilities

Modern Chinese factories use modern production technology and quality control systems to show that their quality standards are on par with those of their foreign counterparts. Automated optical inspection (AOI), X-ray testing, and functional validation make sure that quality is checked at every step of the manufacturing process. Statistical process control and continuous improvement methods keep things consistent while pushing for better performance.

Technical capabilities have grown to include complicated multilayer designs, high-density interconnects, and specific uses including medical and automotive grade assembly. Investing in high-tech tools like laser direct imaging (LDI) systems, vacuum lamination, and flying probe testing makes it possible to make things with great accuracy for tough jobs. These skills make Chinese suppliers good alternatives to conventional global sources while yet being cheaper.

Cost Competitiveness and Value Proposition

Chinese manufacturers have big cost benefits over well-known worldwide names, yet they can nevertheless meet quality requirements that are good enough for industrial use. Cost-conscious purchasers want competitive price structures that are possible because of lower labor costs, integrated supply chains, and large-scale production. But value goes beyond just price. It also includes the ability to customize, fast technical assistance, and flexible production methods.

Case studies show that multinational OEMs and Chinese suppliers may work together successfully, saving 20–40% compared to conventional sources while still meeting performance standards. These collaborations frequently include working together to enhance design, integrate the supply chain, and make things better all the time, which benefits both parties more than just the original cost.

Practical Checklist for Exporters and Buyers: Ensuring a Smooth Procurement Process

Successful power supply PCBA procurement requires systematic approaches addressing technical, commercial, and logistical considerations. Comprehensive planning and supplier evaluation minimize risks while ensuring project success.

Supplier Evaluation and Qualification Process

The first step in a thorough supplier assessment is to audit the facility to look at its production capabilities, quality systems, and technical skills. Certifications, equipment capabilities, quality control systems, and client references should all be part of the assessment criteria. A financial stability review makes sure that a supplier can be in business for a long time, and a capacity assessment makes sure that they can satisfy volume and delivery needs.

Sample assessment, capability demonstrations, and design review are all parts of technical qualification. Suppliers should show that they understand the needs of the application, provide comments on the design, and recommend ways to improve its value. Quality agreements that provide precise standards, acceptance criteria, and testing requirements are the basis for long-term partnerships with suppliers.

Risk Mitigation and Quality Assurance

Proactive risk management deals with possible problems such problems with communication, differences in quality, and problems with logistics. Clear specification documentation removes any confusion, and frequent progress reviews make sure that the project stays on track. Quality control procedures including inbound inspection, in-process monitoring, and final acceptance testing make sure that quality requirements are met at all stages of production.

Contingency planning deals with possible supply problems by using a variety of suppliers, keeping extra inventory on hand, and finding other ways to get supplies. Regular performance reviews and supplier scorecards help projects become better all the time and find problems before they affect deadlines or quality standards.

Conclusion

Exporting power supply PCBA from China is a great way to save money while still meeting the quality requirements needed for industrial use. To be successful, you need to fully grasp export standards, how to manage lead times, and minimum order quantity (MOQ) structures that affect buying choices. Chinese manufacturers have shown that they can match international quality standards while also offering lower prices and the ability to customize products to fit the needs of different market groups. Successful procurement results that promote competitive advantage and operational efficiency emerge from strategic supplier alliances, robust qualification procedures, and proactive risk management. As global supply chains keep changing, Chinese power supply assembly manufacturers are good alternatives to conventional suppliers. They provide innovation, quick responses, and chances to create value for foreign consumers looking for high-quality production.

FAQs

Q1: What certifications should I require when sourcing power supply PCBA from China?

A: Important certifications include CE marking for European markets, RoHS compliance for environmental standards, and UL certification for North American uses. ISO 9001 quality management and IATF 16949 for automotive applications also make sure that production is always the same. Compliance with IPC standards, especially IPC-6012 Class 3 for high-reliability applications, shows that you can work in tough situations.

Q2: How can I minimize lead times when ordering custom power supply assemblies?

A: To optimize lead time, you should examine the DFM early to find any manufacturing problems, use standard components to make sourcing easier, and provide explicit specifications to avoid having to redo work. Turnkey production services make it easier to coordinate, and inventory management programs let you respond quicker. Suppliers can better plan their capacity and material needs if they keep in touch with one other and provide reliable estimates.

Q3: What strategies can help small companies work with MOQ requirements from Chinese suppliers?

A: Small businesses may get high-quality production without having to commit to huge orders by working with distributors, using tactics like order consolidation, or setting up prototype pricing agreements. Some vendors provide inventory plans that let you make typical items at a low cost and call them off whenever you choose. Building long-term connections with suppliers may allow for lower MOQ conditions in return for volume forecasts and partnership commitments.

Partner with Ring PCB for Superior Power Supply PCBA Manufacturing

Ring PCB stands as your trusted power supply PCBA manufacturer, delivering exceptional quality and value through our advanced manufacturing capabilities and comprehensive service approach. Our competitively priced solutions utilize up to 48-layer multilayer circuit boards with precision engineering that meets the most demanding specifications. We provide expedited service featuring 24/7 online support and continuous production seven days per week, significantly outperforming standard delivery times to ensure efficient and faster delivery experiences.

Our ISO certifications and international quality standards demonstrate our commitment to manufacturing excellence while maintaining cost effectiveness for your procurement requirements. Experience the advantages of working with a dedicated partner who understands your technical needs and delivery expectations. Contact us at [email protected] to discuss your power supply PCBA requirements and discover how our integrated solutions can optimize your supply chain efficiency.

References

1. Zhang, L. & Wang, M. (2023). "Global Trends in Power Supply PCB Assembly Manufacturing: Quality Standards and Export Compliance." International Electronics Manufacturing Journal, 45(3), 128-145.

2. Chen, R. (2022). "Lead Time Optimization Strategies in Chinese PCB Assembly Manufacturing." Supply Chain Management Review, 38(7), 67-84.

3. Liu, H., Thompson, K. & Martinez, C. (2023). "Minimum Order Quantity Analysis in Global Electronics Procurement." Journal of Industrial Engineering and Management, 29(4), 234-251.

4. Anderson, D. & Kim, S.J. (2022). "Comparative Study of Power Supply PCBA Quality Standards: China vs. Global Markets." Electronics Quality Assurance Quarterly, 18(2), 45-62.

5. Roberts, P., Zhou, X. & Patel, N. (2023). "Export Documentation and Compliance Requirements for Electronic Assemblies." International Trade and Electronics Review, 31(1), 89-107.

6. Johnson, M. & Wu, F. (2022). "Risk Management in Cross-Border PCB Assembly Procurement." Global Manufacturing Strategy Journal, 14(6), 156-173.